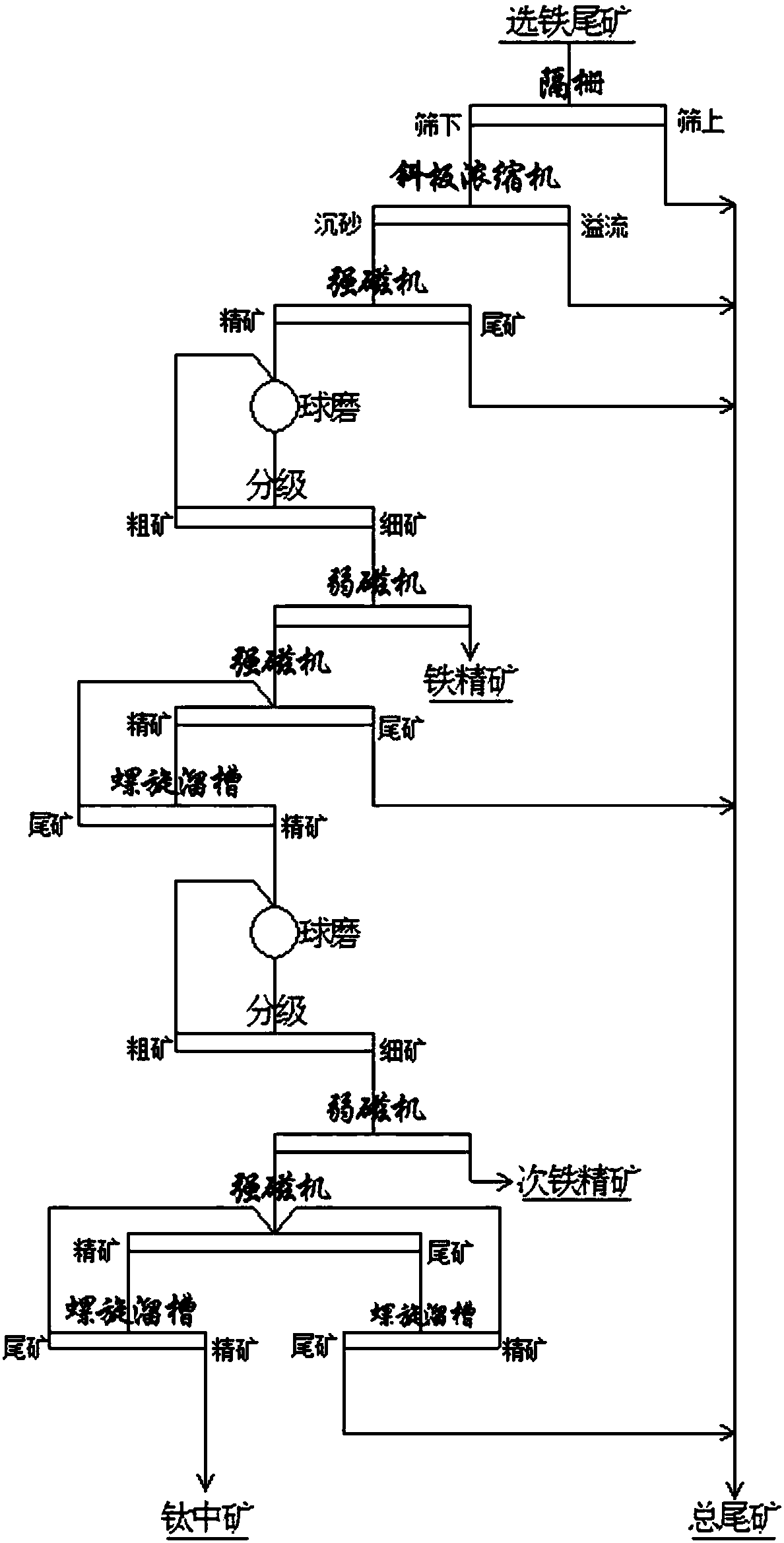

Method for sorting titanium middling from iron-separating tailings

A technology for medium titanium ore and tailings, which is applied in the field of separating titanium medium ore from iron beneficiation tailings, can solve the problems of high energy consumption and low metal recovery rate, and achieves high metal recovery rate, simple process flow, and reduced power consumption. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043]The various technical indicators in the raw ore are: silicon grade 28.1wt%, sulfur grade 3.8wt%, titanium grade 3.8wt%, fineness 18wt%.

[0044] This implementation provides a kind of method for separating titanium medium ore from iron-selection tailings, comprising the following steps:

[0045] Step 1. Pass the iron dressing tailings through the screen to remove impurities in the slurry, and then concentrate through the inclined plate thickener. The inclined plate grit concentration is 20.5wt%, and the content of ≥ 45 micron minerals in the inclined plate overflow is 4.6wt%.

[0046] Step 2, high-strength magnetic separator throwing tails: the concentrated ore pulp is subjected to strong magnetic separation to obtain magnetic materials and non-magnetic materials. The titanium grade of the magnetic materials is 9.3wt%, and the non-magnetic materials are directly used as magnetic separation tailings emission;

[0047] Step 3, one-stage grinding: the magnetic material is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com