CsPbBr3 Nanocrystal and method to synthesize CsPbBr3 nanocrystals of different dimensions based on microwave method

A nanocrystal and microwave method technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve fine control, simple and controllable process, and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take 690mg PbBr 2 , 25ml of octadecene (ODE) and 25ml of diethylene glycol butyl ether (DGBE) were placed in a three-necked flask, heated to 120°C for 1 hour under vacuum, and injected with 9ml of dry oleic acid (OA) and 1ml of oleylamine (OAm), Then warm up to 150°C until PbBr 2 After completely dissolving, cool naturally to room temperature for later use.

[0034] Take 0.8g Cs 2 CO 3 , 2.4ml OA and 30ml ODE were placed in a three-necked flask, heated to 120°C for 1 hour under vacuum, and then heated to 150°C until Cs 2 CO 3 Cool to room temperature after complete dissolution. The Cs precursor needs to be heated to 100 °C before use to avoid the precipitation of Cs-oleate from the ODE.

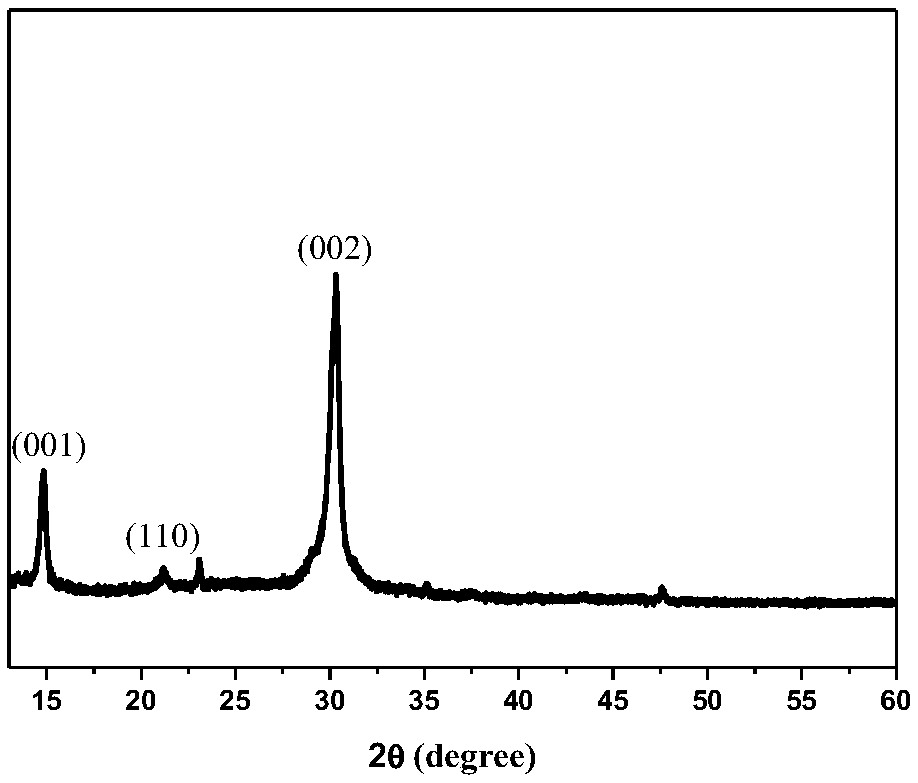

[0035] Take 5ml of the above PbBr 2 The precursor and 0.4ml of the above Cs precursor were placed in a 2 Mix in a 10ml glass bottle of gas, and then put it into a microwave oven to synthesize at 400W. After 1min, take out the glass bottle and put it in ice water to cool down, s...

Embodiment 2

[0038] The only difference with embodiment 1 is that this embodiment PbBr 2 In the preparation of the precursor, 8 ml of oleic acid (OA) and 2 ml of oleylamine (OAm) were used, and the others were the same as those in Example 1, which will not be repeated here.

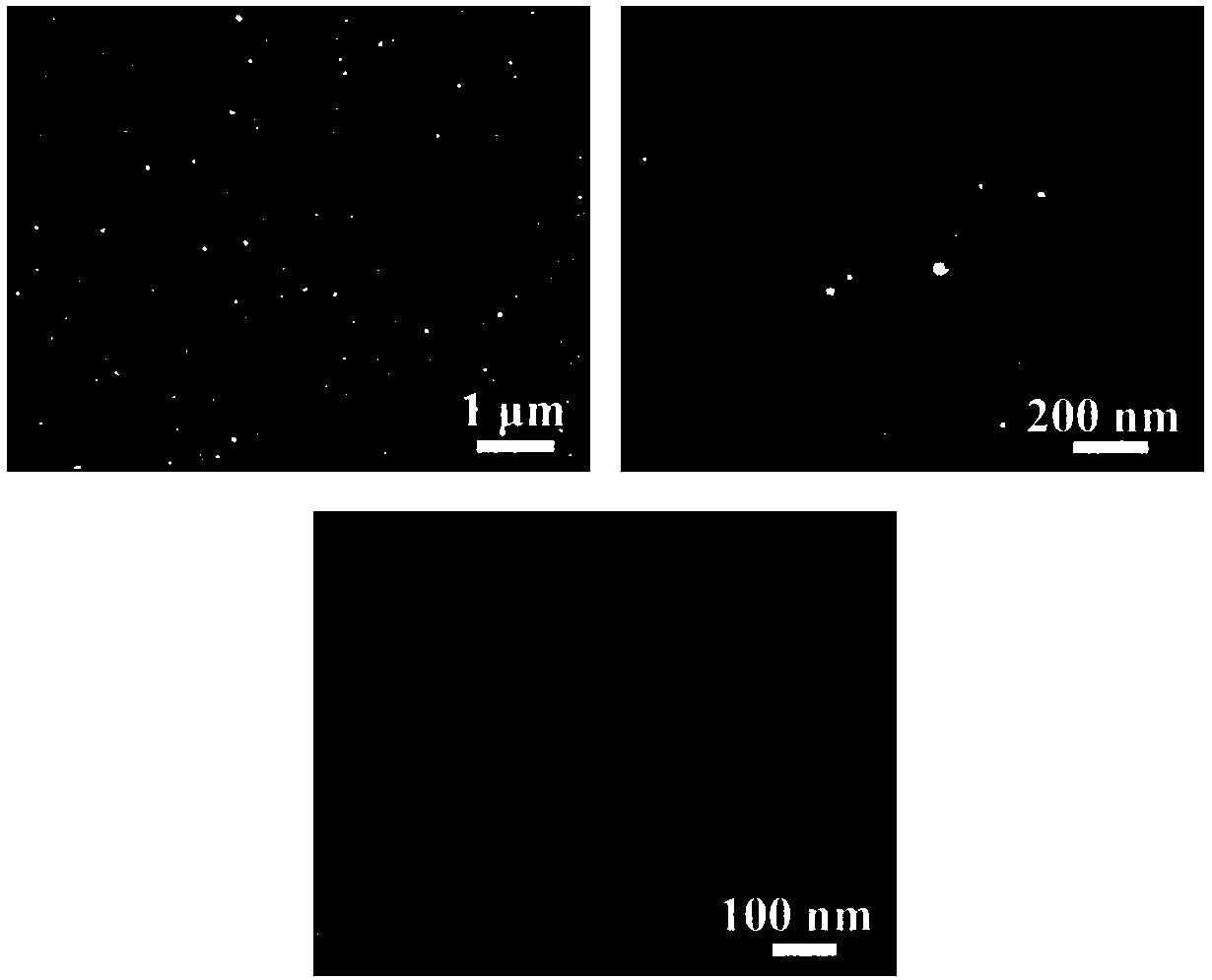

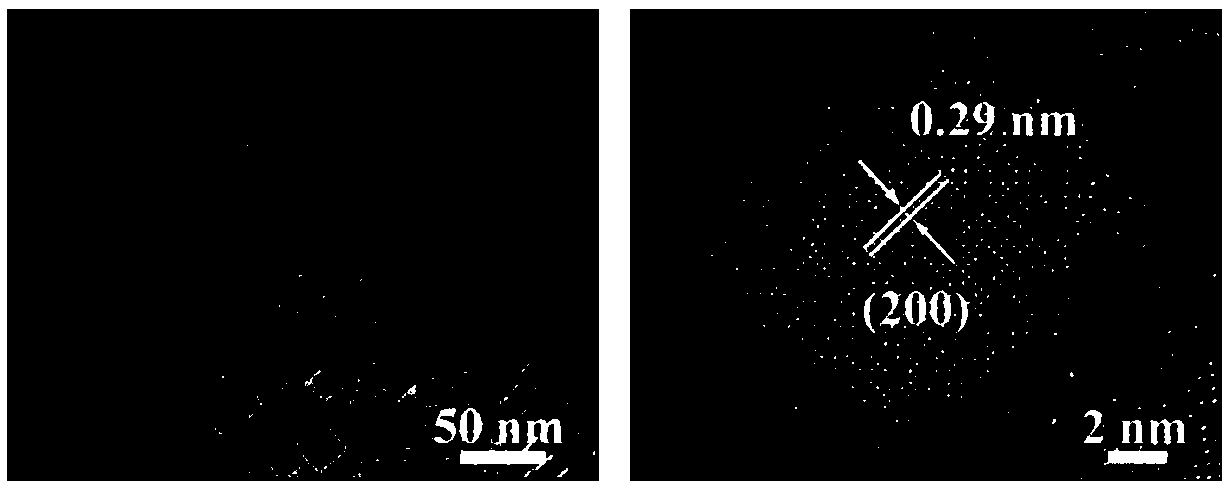

[0039] The CsPbBr prepared by this embodiment 3 Scanning electron microscope (SEM) and transmission electron microscope (TEM) images of perovskite nanocrystals at different magnifications Figure 5 with Image 6 , indicating that the as-prepared material is 1D CsPbBr 3 Nano stave.

Embodiment 3

[0041] The only difference with embodiment 1 is that this embodiment PbBr 2 In the preparation of the precursor, 6.5 ml of oleic acid (OA) and 4 ml of oleylamine (OAm) were used, and the others were the same as those in Example 1, which will not be repeated here.

[0042] The CsPbBr prepared by this embodiment 3 Scanning electron microscope (SEM) and transmission electron microscope (TEM) images of perovskite nanocrystals at different magnifications Figure 7 with Figure 8 , indicating that the as-prepared material is a 2D CsPbBr 3 Nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com