Method for preparing zirconia from solid waste zirconium

A zirconia and solid technology, applied in the field of resource utilization of solid waste, can solve the problems of low production cost, environmental pollution, etc., achieve the effects of low equipment requirements, broad market prospects, and avoid disposal problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

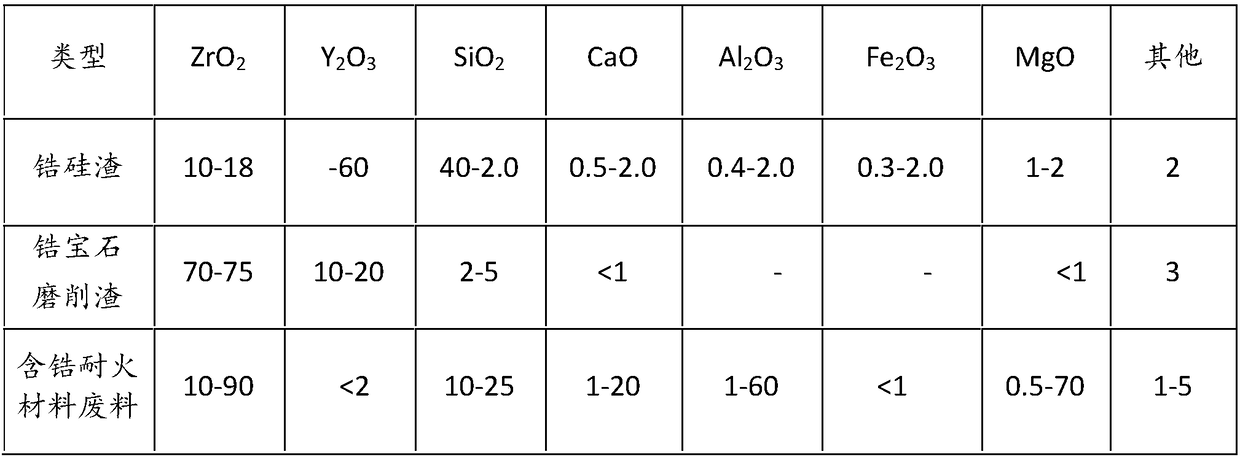

[0059] A method for preparing zirconia with solid waste zirconium, comprising the following steps:

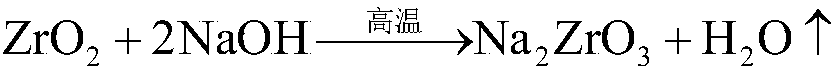

[0060] (1) The zirconia ceramic waste is pulverized and ground, and mixed with NaOH at a mass ratio of 1:1.1. After mixing, it is moved into a stainless steel pot and roasted at 800 ° C for 3 hours to obtain zirconium salt;

[0061] (2) washing the zirconium salt with deionized water, then adding it to hydrochloric acid with a concentration of 21 wt % and heating for 3 h to obtain a reaction product, and carrying out solid-liquid separation on the reaction product to obtain a transformation liquid, to the described Sulfuric acid is added in the transformation liquid to carry out the primary reaction to obtain basic zirconium sulfate as the first precipitate, the first precipitate is further reacted with sulfuric acid to obtain zirconium sulfate, and the zirconium sulfate is prepared as 0.25mol / L zirconium sulfate solution for backup;

[0062] (3) 0.25mol / L NaOH solution was dr...

Embodiment 2

[0067] A method for preparing zirconia with solid waste zirconium, comprising the following steps:

[0068] (1) The zirconia artificial gemstone processing and grinding slag is pulverized and ground, and mixed with NaOH at a mass ratio of 1:1.5. After mixing, it is moved into a stainless steel pot and roasted at 700 ° C for 3 hours to obtain zirconium salt;

[0069] (2) washing the zirconium salt with deionized water, then adding it to hydrochloric acid with a concentration of 23wt% and heating for 3h to obtain a reaction product, and carrying out solid-liquid separation on the reaction product to obtain a transformation liquid, and to the described Sulfuric acid is added in the transformation liquid to carry out the initial reaction, to obtain basic zirconium sulfate as the first precipitate, the first precipitate is further reacted with sulfuric acid to obtain zirconium sulfate, and the zirconium sulfate is prepared into 0.5 mol / L zirconium sulfate solution for backup;

[0...

Embodiment 3

[0075] A method for preparing zirconia with solid waste zirconium, comprising the following steps:

[0076] (1) The zirconia composite refractory waste processing and grinding slag is pulverized and ground, and mixed with NH 4 OH was mixed at a mass ratio of 1:1.3, and then moved into a stainless steel pot after mixing, and calcined at 1000 °C for 3 hours to obtain zirconium salt;

[0077] (2) washing the zirconium salt with deionized water, then adding it to hydrochloric acid with a concentration of 24 wt % and heating for 3 h to obtain a reaction product. The reaction product is subjected to solid-liquid separation to obtain a transformation liquid. Sulfuric acid is added in the transformation liquid to carry out the initial reaction, to obtain basic zirconium sulfate as the first precipitate, the first precipitate is further reacted with sulfuric acid to obtain zirconium sulfate, and the zirconium sulfate is prepared into 3.0 mol / L zirconium sulfate solution for backup;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com