Circulating water zero drainage separate recycling treating device and treating method thereof

A treatment device and a technology of quality separation and reuse, which are applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Increased consumption and other issues, to achieve the effect of reducing treatment costs, zero discharge, and reducing the amount of supplementary water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

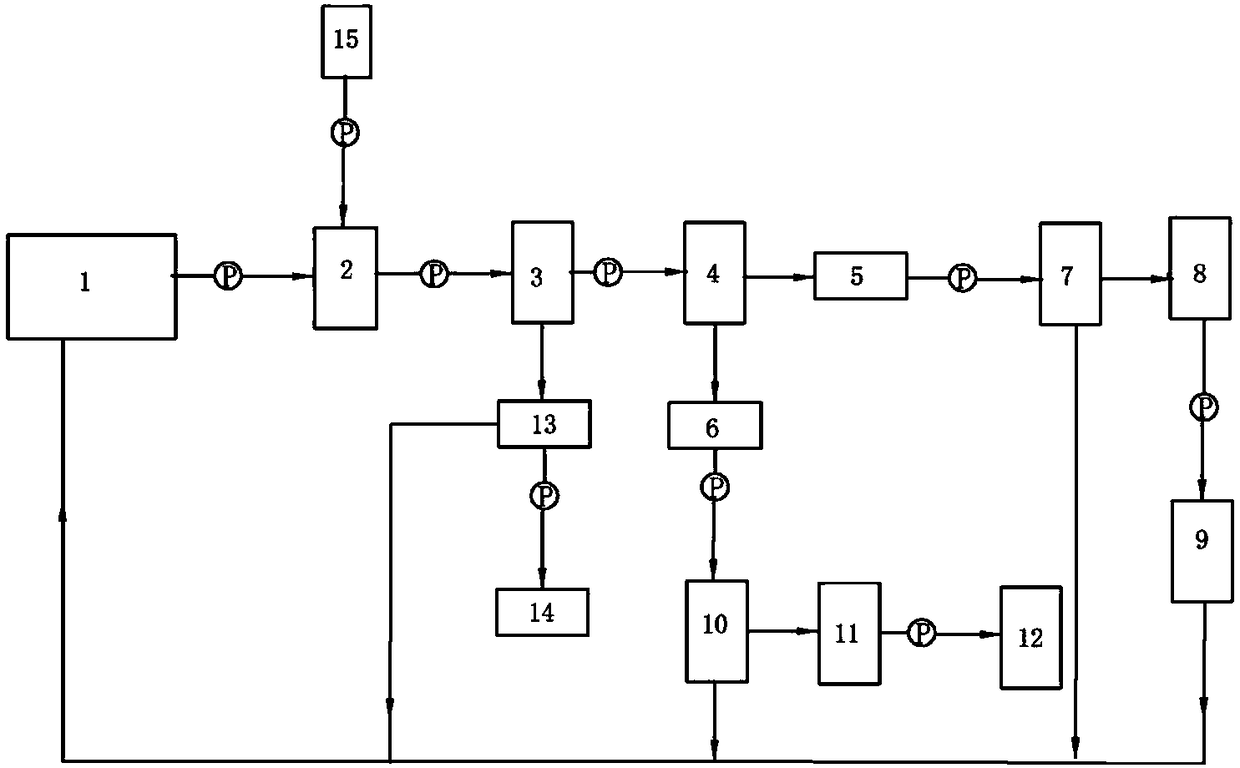

[0029] same figure 1 It is a structural schematic diagram of an embodiment of the present invention applied in a circulating water system.

[0030] The device of the recycling water zero efflux treatment method according to the present invention comprises a circulating water sump 1, a mixing device 2, a filter aid dosing system 15, a filtering device 3, a sewage pool 13, and a filter press 14. Nanofiltration device 4, nanofiltration filtrate collection tank 5, nanofiltration retentate collection tank 6, electrodialysis devices 7, 10, electrodialysis concentrated water collection tanks 8, 11, evaporation crystallizer 12, electrochemical treatment device 9 .

[0031] The filter aid dosing system 15 includes a chemical tank, a diaphragm metering pump, and a pipeline mixer. The filter aid and the sewage from the circulating water sump 1 enter the mixing device 2 after passing through the manifold of the pipeline mixer.

[0032] The filter device 3 is a secondary filter device, i...

Embodiment 2

[0044] The quality-based recycling treatment of circulating water with zero effluent is the same as that in Example 1. An enterprise's circulating cooling open circuit system, the conductance of circulating water and sewage is 1860μS / cm, Cl - About 320mg / L, total hardness 350mg / L, turbidity 13NTU, treated water volume 100m 3 / h.

[0045] The method adopted in this embodiment includes the following steps:

[0046] (1) Filter aid pretreatment: Discharge 100m of circulating water in the circulating water collection tank 1 3 / h and the filter aid 0.02mg / L polyaluminum chloride and 0.01mg / L polyacrylamide drawn from the filter aid dosing device 15 are added to the mixing device 2 through the pipeline mixer, and passed through the filter device 3 successively through the multi-media Filter to remove impurities with a particle size of 10 μm or more in the sewage. Through a precision filter, remove impurities with a particle size of 5 μm or more to reduce suspended solids and turbid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com