Soil conditioner and preparation method thereof

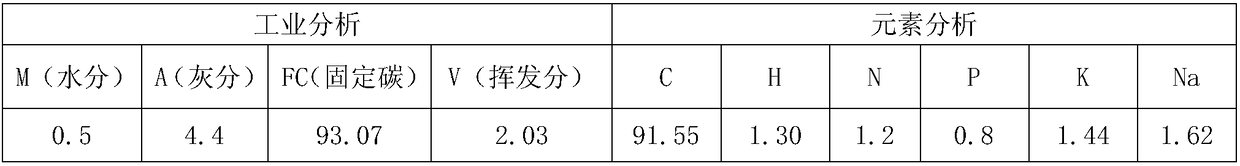

A technology of soil improver and semi-coke powder, which is applied in the field of soil improver and its preparation, can solve the problems of increasing new uses of semi-coke powder, and achieve the effect of superior performance, small particle size, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation process of the soil conditioner of the present embodiment is as follows:

[0035] Soak low-modified pulverized coal in a mixed acid with a mass ratio of nitric acid and phosphoric acid of 3:1, heat to 60°C, and stir for 2 hours at a stirring rate of 3600r / h. In order to protect the pyrolysis equipment in the later stage, adjust the pH to neutral, filter and dry to obtain ash-free and low-deterioration pulverized coal. Low-temperature dry distillation of deashed and low-modified pulverized coal in an electric furnace. The heating rate of the electric furnace is set at 10°C / min, the final pyrolysis temperature is 800°C, and the residence time is 40min. Grind to 300 mesh, after activating the pores, soak in a mixture of sodium nitrate and potassium phosphate with a mass ratio of 1:1, heat to 40°C, and stir for 0.5h at a stirring rate of 1800r / h to absorb the necessary sodium, Potassium, nitrogen, phosphorus and other elements until the adsorption is satura...

Embodiment 2

[0040] The preparation process of the soil conditioner of the present embodiment is as follows:

[0041] Soak low-modified pulverized coal in a mixed acid with a mass ratio of nitric acid and phosphoric acid of 3:1, heat to 60°C, and stir for 2 hours at a stirring rate of 3600r / h. In order to protect the pyrolysis equipment in the later stage, adjust the pH to neutral, filter and dry to obtain ash-free and low-deterioration pulverized coal. Low-temperature dry distillation of deashed and low-modified pulverized coal in an electric furnace. The heating rate of the electric furnace is set at 10°C / min, the final pyrolysis temperature is 800°C, and the residence time is 40min. Grind to 200 mesh, after activating the pores, soak in a mixture of sodium nitrate and potassium phosphate with a mass ratio of 1:1, heat to 40°C, and stir for 0.5h at a stirring rate of 1800r / h to absorb the necessary sodium, Potassium, nitrogen, phosphorus and other elements until the adsorption is satura...

Embodiment 3

[0043] The preparation process of the soil conditioner of the present embodiment is as follows:

[0044] Soak low-modified pulverized coal in a mixed acid with a mass ratio of nitric acid and phosphoric acid of 5:1, heat to 80°C, and stir for 4 hours at a stirring rate of 4800r / h. In order to protect the pyrolysis equipment in the later stage, adjust the pH to neutral, filter and dry to obtain ash-free and low-deterioration pulverized coal. Low-temperature dry distillation of deashed and low-modified pulverized coal in an electric furnace. The heating rate of the electric furnace is set at 10°C / min, the final pyrolysis temperature is 800°C, and the residence time is 40min. Grind to 250 mesh, after activating the pores, soak in a mixture of sodium nitrate and potassium phosphate with a mass ratio of 2:1, heat to 60°C, and stir for 1 hour at a stirring rate of 3000r / h to absorb sodium and potassium necessary for crops , nitrogen, phosphorus and other elements until the adsorpti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com