Recycling method of nigrosine mud iron

A nigrosine and iron slime technology, applied in the field of nigrosine, can solve the problems of inapplicable iron slime recovery and recovery, and achieve the effects of realizing economic benefits and environmental protection, reducing environmental pollution, and reducing product loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

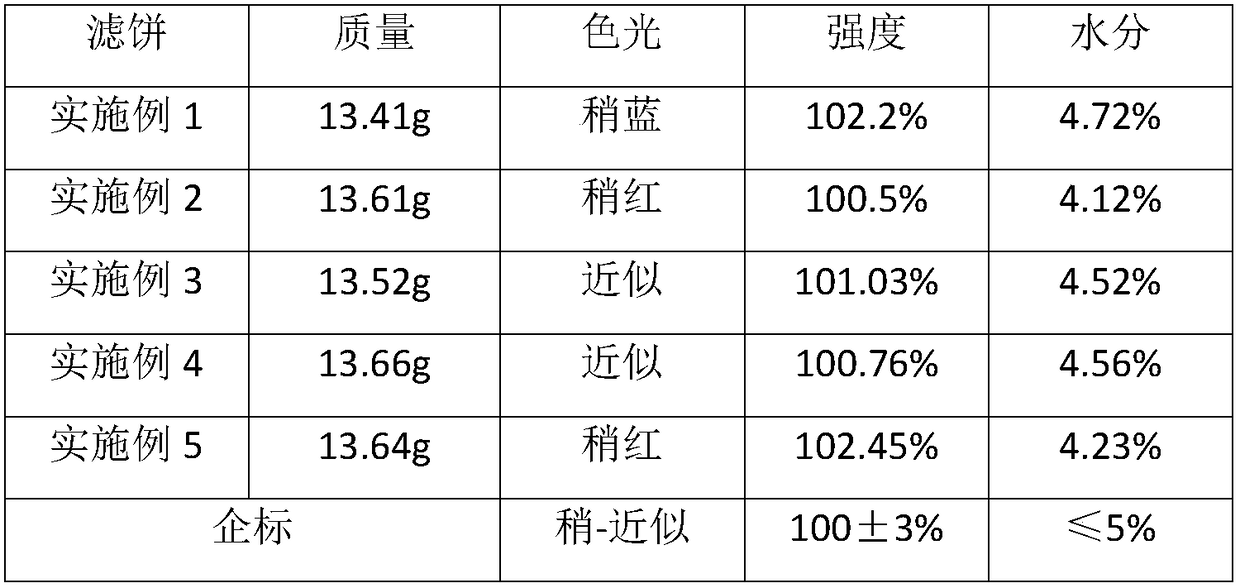

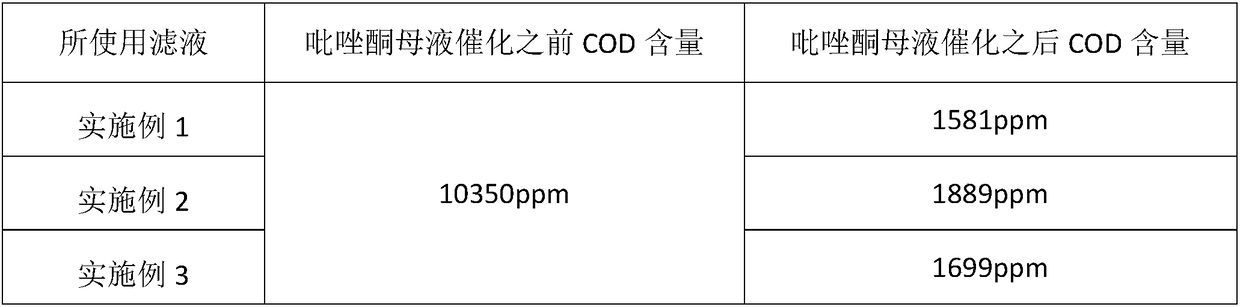

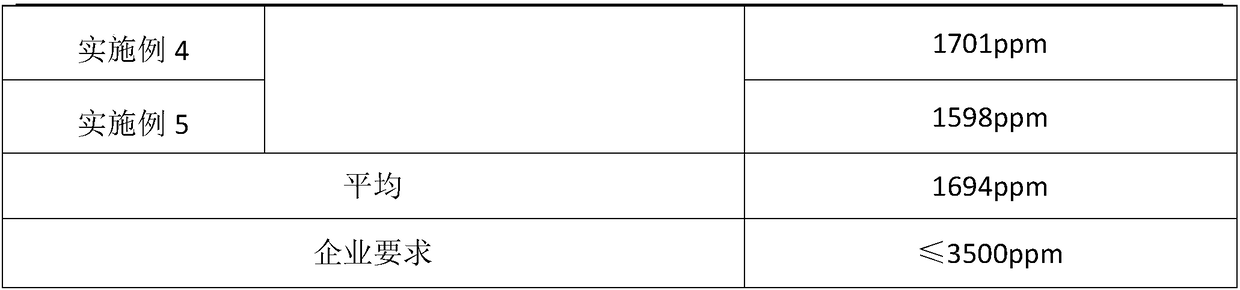

Examples

Embodiment 1

[0057] 1) Beat 50g of aniline black iron mud wet product with 400ml water for 30min;

[0058] 2) Add 62g of concentrated sulfuric acid dropwise to the beaten iron mud, heat up to 60°C, stir and react for 2h;

[0059] 3) After the reaction is over, filter while it is hot, and recover the filtrate; the filter cake is washed with about 100ml of water, dried, recovered, and used as a plastic ink product;

[0060] 4) The filtrate recovered in step 3) is used to treat the phenylpyrazolone mother liquor wastewater.

Embodiment 2

[0062] 1) Beat 46g of wet aniline black iron mud with 400ml water for 25min;

[0063] 2) Add 55.2g of concentrated sulfuric acid dropwise to the beaten iron mud, heat up to 65°C, and stir for 1.5h;

[0064] 3) After the reaction is over, filter while it is hot, and recover the filtrate; the filter cake is washed with about 100ml of water, dried, recovered, and used as a plastic ink product;

[0065] 4) The filtrate recovered in step 3) is used to treat the phenylpyrazolone mother liquor wastewater.

Embodiment 3

[0067] 1) Beat 54g of aniline black iron mud wet product (with a water content of 55%) with 400ml of water for 35min;

[0068] 2) Add 70.2g of concentrated sulfuric acid dropwise to the beaten iron mud, heat up to 62°C, stir and react for 2.5h;

[0069] 3) After the reaction is over, filter while it is hot, and recover the filtrate; the filter cake is washed with about 100ml of water, dried, recovered, and used as a plastic ink product;

[0070] 4) The filtrate recovered in step 3) is used to treat the phenylpyrazolone mother liquor wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com