Medium for fermentation production of FR901379 and method thereof

A FR901379, fermentation culture technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of FR901379 low fermentation unit, low dissolved oxygen, high viscosity of fermentation broth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Transfer 3% of the cultured seeds into 30L fermentation medium sterilized at 120°C for 30 minutes and then cooled to 24-26°C. The composition of the fermentation medium, the mass (g) / volume (L) ratio is: fructose 130. Corn gluten powder 17, casein 8, yeast peptone 8, magnesium sulfate 2, dipotassium hydrogen phosphate 0.75, calcium carbonate 3, defoamer 1, and the rest is water.

[0031] During the fermentation process, the temperature is 24-26°C, the ventilation volume is 1VVM, and the initial rotation speed is 150rpm. During the process, the rotation speed is adjusted between 150 and 600rpm so that the dissolved oxygen is not lower than 20%.

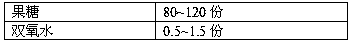

[0032] The fructose was prepared into a 500g / L aqueous solution and sterilized at 120°C for 30 minutes before use, and diluted with hydrogen peroxide to a 30% aqueous solution for use. Fermentation starts at 90 hours, and fructose and hydrogen peroxide are added to the fermenter respectively. The method of addition is continuous...

Embodiment 2

[0034] Transfer the cultured seeds to 300L fermentation medium at 120°C for 30 minutes and then cool to 24-26°C at a ratio of 3%. The composition of the fermentation medium is as follows: fructose 140. Corn gluten powder 15, casein 7.5, yeast peptone 9, magnesium sulfate 2, dipotassium hydrogen phosphate 0.8, calcium carbonate 3, defoamer 1, and the rest is water.

[0035] During the fermentation process, the temperature is 24-26°C, the ventilation rate is 1VVM, and the initial speed is 80rpm. During the process, the speed is adjusted between 80~250rpm so that the dissolved oxygen is not lower than 20%.

[0036] The fructose was prepared into a 500g / L aqueous solution and sterilized at 120°C for 30 minutes before use, and diluted with hydrogen peroxide to a 30% aqueous solution for use. Fermentation starts at 80 hours, and fructose and hydrogen peroxide are added to the fermenter respectively. The method of addition is continuous and uninterrupted, and the addition is stopped ...

Embodiment 3

[0038] Transfer the cultured seeds into 3000L fermentation medium at 120°C for 30 minutes and cool to 24-26°C at a ratio of 2.5%. The composition of the fermentation medium is: mass (g) / volume (L) ratio: fructose 150, corn gluten powder 20, casein 7.5, yeast peptone 5, magnesium sulfate 2, dipotassium hydrogen phosphate 0.6, calcium carbonate 3, defoamer 0.7, and the rest is water.

[0039] During the fermentation process, the temperature is 24-26°C, the ventilation rate is 1VVM, and the initial speed is 60rpm. During the process, the speed is adjusted between 60 and 200rpm so that the dissolved oxygen is not lower than 20%.

[0040] The fructose was prepared into a 500g / L aqueous solution and sterilized at 120°C for 30 minutes before use, and diluted with hydrogen peroxide to a 30% aqueous solution for use. Fermentation starts at 76 hours, and fructose and hydrogen peroxide are added to the fermenter respectively. The method of addition is continuous and uninterrupted, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com