Three-dimensional heat-structure coupling analysis method for carbon fiber wrapped composite material cylinders

A technology of winding composite materials and coupling analysis, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the complex thermal-structural coupling analysis, and it is difficult to find thermal-structural coupling performance analysis methods for carbon fiber winding composite materials and other problems, to achieve the effect of simple analysis method, significant practical significance, and wide application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

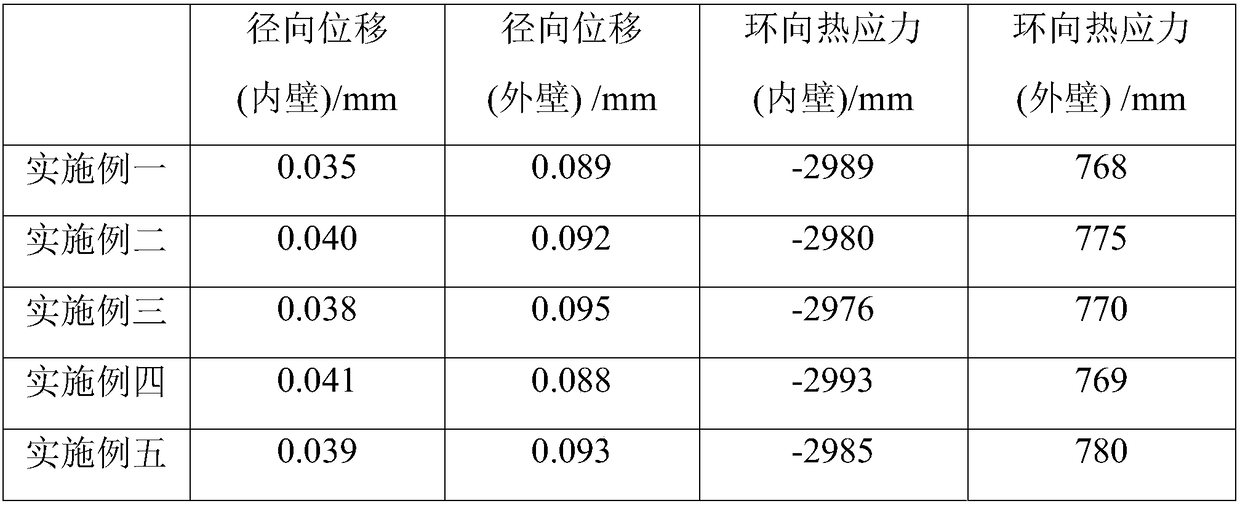

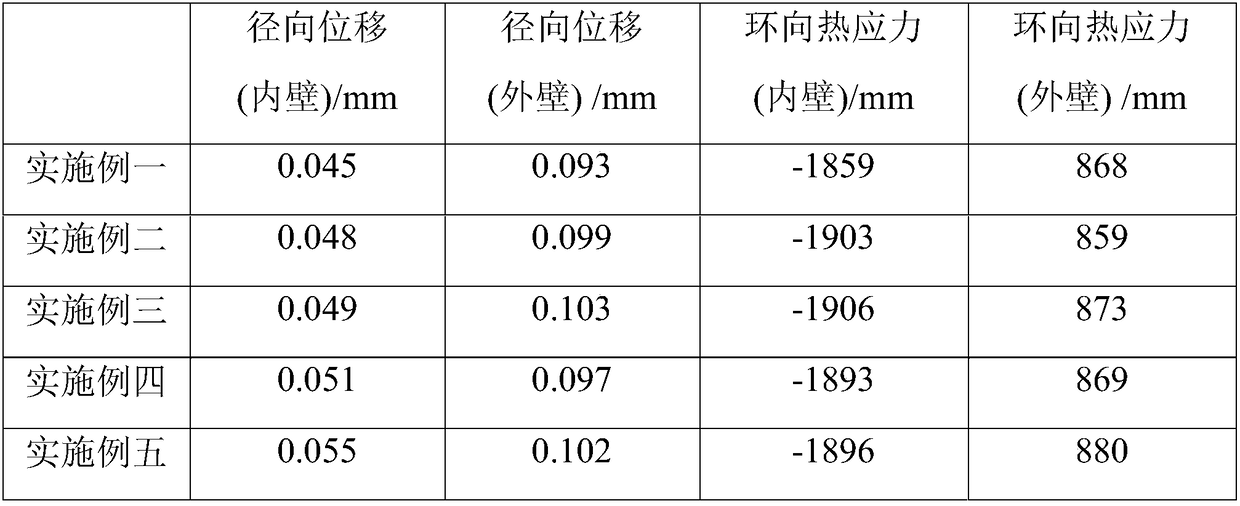

Embodiment 1

[0033] The invention provides a three-dimensional thermal-structural coupling analysis method of a carbon fiber wound composite material cylinder, comprising the following steps:

[0034] S101: Establish an overall finite element analysis model of the carbon fiber wound composite material in the finite element analysis software ANSYS. Among them, the raw material components of the carbon fiber winding composite material include: 43 parts by weight of carbon fiber, 1 part by weight of polypropylene with a number average molecular weight of 300000, 1 part by weight of polycarbonate with a number average molecular weight of 80000, and 1 part by weight of polycarbonate with a number average molecular weight of 1 part by weight of polysulfone of 30000, 3 parts by weight of magnesium, 2 parts by weight of europium, 9 parts by weight of manganese, and 2 parts by weight of aluminum.

[0035] S102: Carry out mesh division on the three-dimensional model obtained by modeling in S101. Am...

Embodiment 2

[0039] The invention provides a three-dimensional thermal-structural coupling analysis method of a carbon fiber wound composite material cylinder, comprising the following steps:

[0040] S101: Establish an overall finite element analysis model of the carbon fiber wound composite material in the finite element analysis software ANSYS. Among them, the raw material components of the carbon fiber winding composite material include: 50 parts by weight of carbon fiber, 2 parts by weight of polyamide with a number average molecular weight of 100000, 2 parts by weight of polyvinyl chloride with a number average molecular weight of 90000, and 6 parts by weight of lanthanum 6 parts by weight, 6 parts by weight of manganese and 6 parts by weight of aluminum.

[0041] S102: Carry out mesh division on the three-dimensional model obtained by modeling in S101. Among them, the grid division specifically includes: using 20-node three-dimensional solid coupling elements, each node includes 3 ...

Embodiment 3

[0045] The invention provides a three-dimensional thermal-structural coupling analysis method of a carbon fiber wound composite material cylinder, comprising the following steps:

[0046] S101: Establish an overall finite element analysis model of the carbon fiber wound composite material in the finite element analysis software ANSYS. Among them, the raw material components of the carbon fiber winding composite material include: 35 parts by weight of carbon fiber, 2 parts by weight of polyphenylene ether with a number average molecular weight of 200,000, 2 parts by weight of polycarbonate with a number average molecular weight of 50,000, magnesium 5 parts by weight, 6 parts by weight of copper and 6 parts by weight of aluminum.

[0047] S102: Carry out mesh division on the three-dimensional model obtained by modeling in S101. Among them, the grid division specifically includes: using 20-node three-dimensional solid coupling elements, each node includes 3 degrees of freedom of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com