Technology for centralized recycling of coal gas and oil gas in coal chemical engineering industry

A technology of coal chemical industry and gas, which is applied in the direction of chemical instruments and methods, combined devices, and separation of dispersed particles, to achieve the effects of less pollution, safety assurance, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

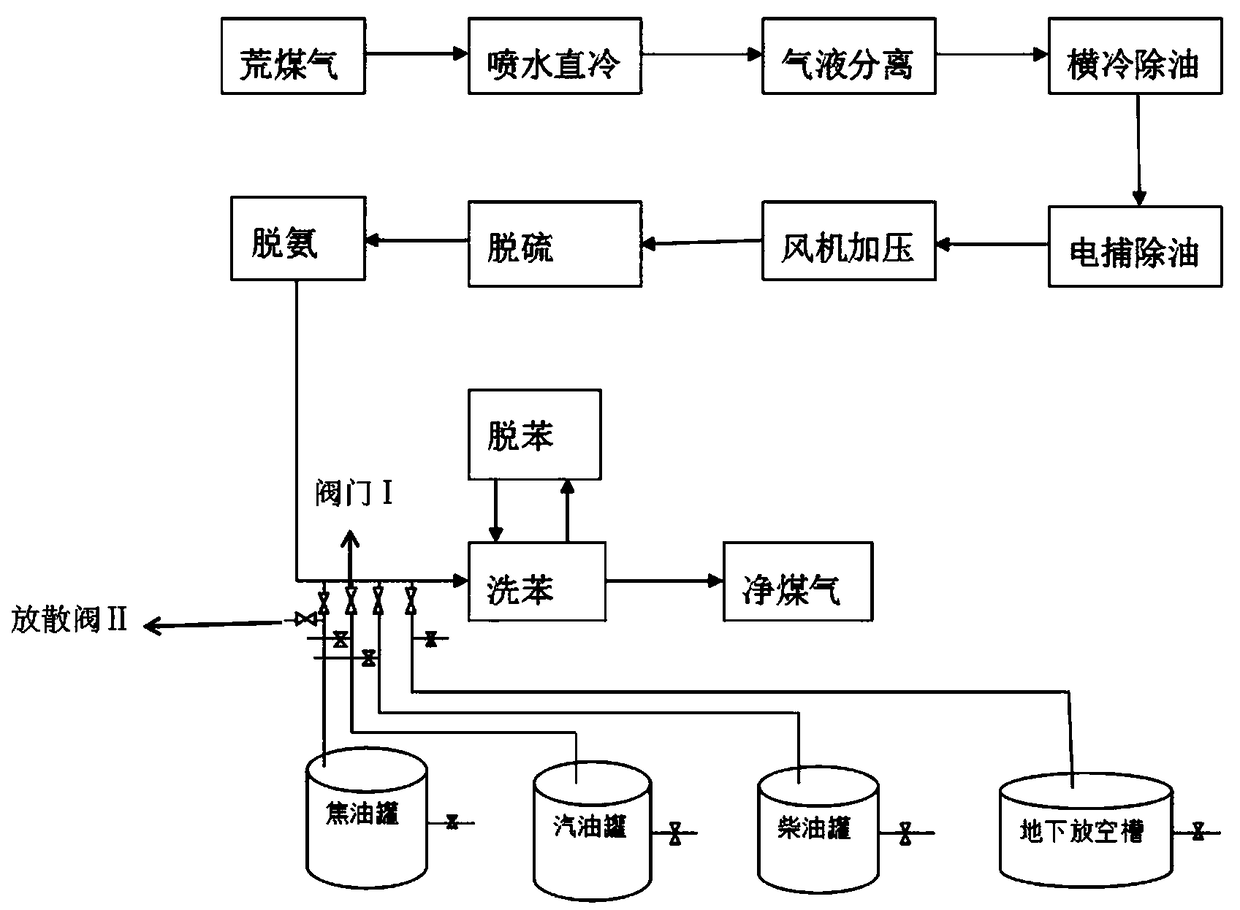

[0028] Such as figure 1 As shown, the coal gas purification process is that the raw coal gas produced by coal pyrolysis is directly cooled by spraying water → gas-liquid separation → horizontal cooling for oil removal → electric capture for oil removal → fan pressurization → desulfurization → deammonization → benzene elution.

[0029] A process for the centralized recovery of coal gas and oil gas in the coal chemical industry. The tar tanks in the coal chemical industry and the co-production of tar to produce gasoline and diesel oil tanks and diesel tanks, and the tank tops of underground emptying tanks are respectively equipped with breathing pipes. The breathing pipeline is connected with the gas positive pressure pipeline before the benzene eluting device after the pressurized fan in the gas purification to form a pipe network together, and the gas pressure in the pipe network is consistent.

[0030] The gas pressure in each tank is consistent with the gas space of the enti...

Embodiment 2

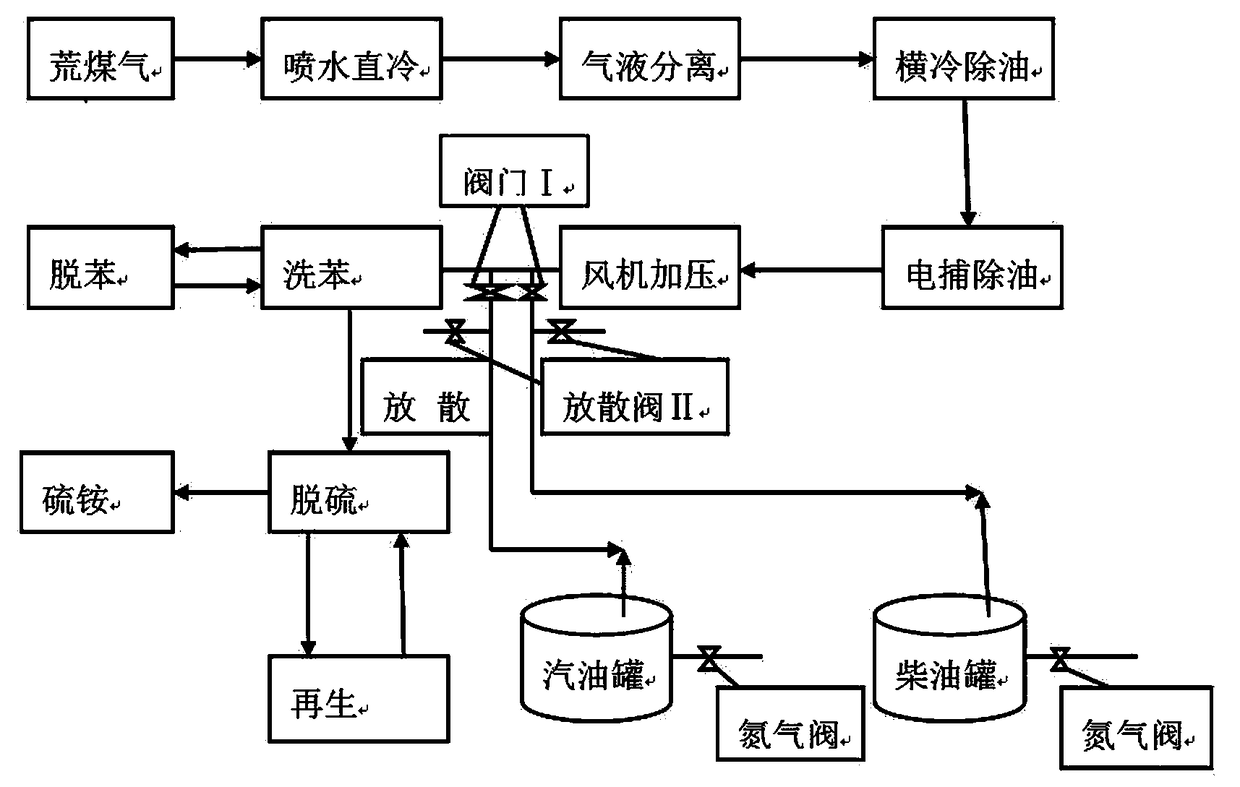

[0034] Such as figure 2 As shown, the purification process of coal gas is that the raw coal gas produced by coal pyrolysis is directly cooled by spraying water → gas-liquid separation → horizontal cooling for oil removal → electric capture for oil removal → fan pressurization → benzene elution → desulfurization → ammonium sulfate, gas get cleansed.

[0035] The tar tanks and tar co-production gasoline and diesel tanks for producing gasoline and diesel oil, and the breathing pipes on the top of the tanks in the underground emptying tanks are still connected to the gas positive pressure pipes in front of the benzene eluting device after the pressurized fan in the gas purification process. Form a pipe network.

[0036] The difference from the gas purification process in Example 1 is that the benzene elution process in Example 2 is placed in front of the desulfurization and ammonium sulfate process. The purpose is to remove the organic matter before the gas desulfurization, so a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com