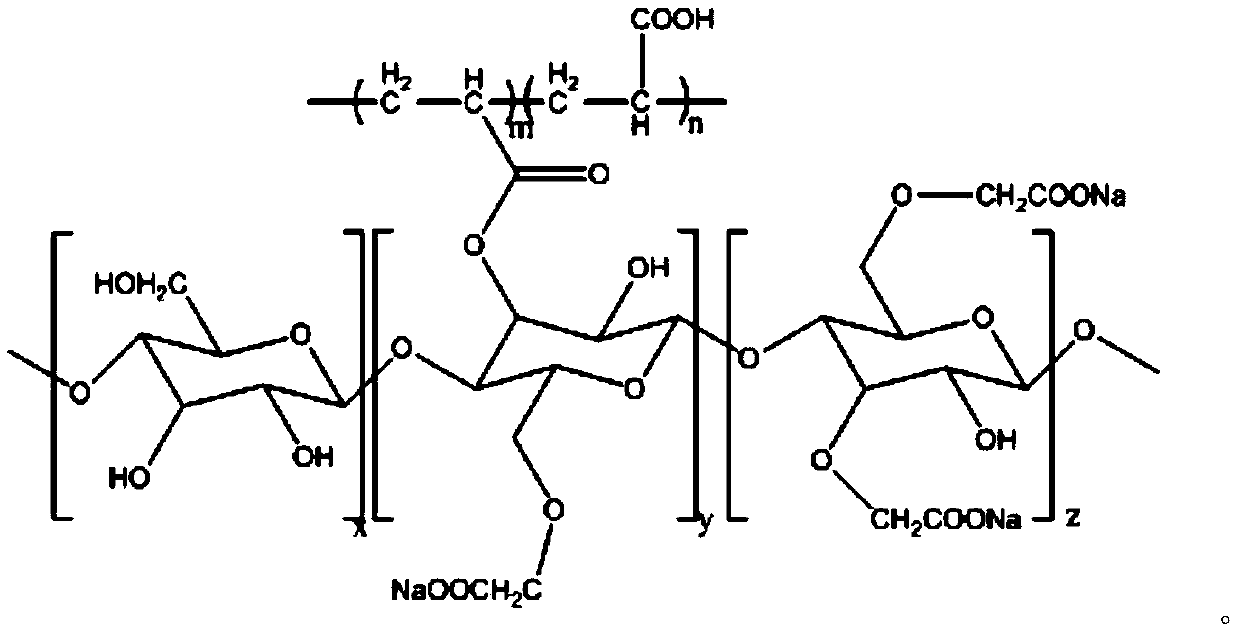

A kind of polymer copolymer material with hemostatic effect and preparation method thereof

A technology of high molecular copolymer and hemostatic effect, which can be used in drug delivery, pharmaceutical formulations, bandages, etc. It can solve the problems of unstable hemostatic effect, difficulty in controlling the amount of powder, and washing away, so as to achieve good hemostatic effect, low cost, and human body safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

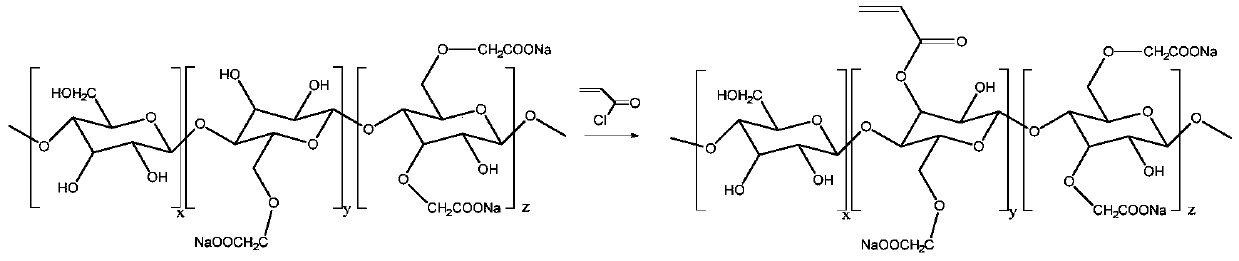

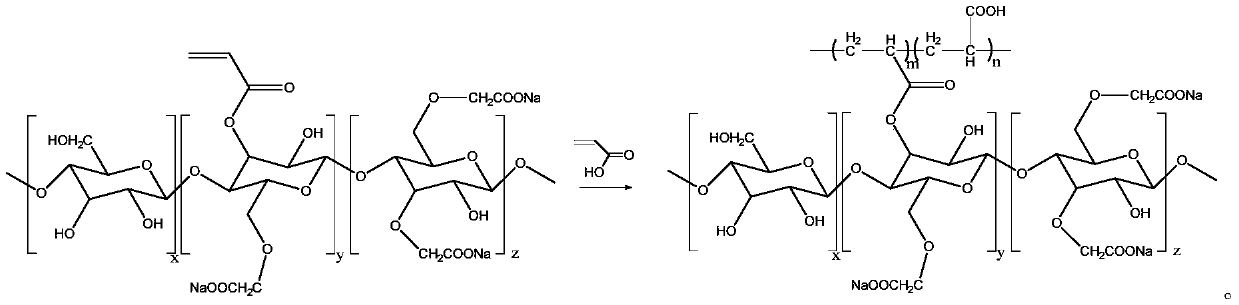

Method used

Image

Examples

Embodiment 1

[0037] (1) Taking carboxymethyl cellulose gauze as raw material, putting it into a NaOH solution with a mass fraction of 20% to carry out dipping and alkalization, the dipping time is 32min, and the alkalization temperature is 15°C to become alkalized cellulose;

[0038] (2) Centrifuge the alkalized cellulose, the mass ratio of the alkalized cellulose before and after pressing is 3.5:1, put it into the ethanol solution of chloroacetic acid with a concentration of 0.5mol / L, heat, the temperature is 65°C, and carry out ether Etherification reaction, etherification time 30min, obtain etherification product, etherification product is the carboxymethyl cellulose gauze of different degree of substitution, the carboxyl mass fraction of described carboxymethyl cellulose gauze is 10%;

[0039] (3) Centrifuge the etherification product, wash it with ethanol solution, then remove ethanol by centrifugation, dry it in a vacuum drying oven less than 50°C, and cut it;

[0040] (4) Arrange th...

Embodiment 2

[0043] (1) Use clean regenerated cellulose gauze as the raw material, place it in a temperature-controllable flat alkalization tank, spread it on the bottom of the alkalization tank, and put it into the NaOH solution with a mass fraction of 25% for dipping and alkalization , to become alkalized cellulose, wherein the mass volume ratio of regenerated cellulose gauze to NaOH solution is 1g:12ml, and the soaking time is 25min. During dipping, a roller is used to repeatedly squeeze the gauze to ensure sufficient dipping and alkali solution absorption, alkalized The temperature is controlled at 10°C;

[0044] (2) Take out the alkalized cellulose from the alkalization tank, place it in a low-speed centrifuge for centrifugal pressing, remove excess lye, the mass ratio of alkalized cellulose before and after centrifugal pressing is 3:1, and chloroacetic ethanol The solution is placed in an etherification reaction tank, wherein the mass ratio of chloroacetic acid to regenerated fiber is ...

Embodiment 3

[0049] (1) Use clean regenerated cellulose gauze as raw material, place it in a temperature-controllable flat alkalization tank, spread it on the bottom of the alkalization tank, and put it into the NaOH solution with a mass fraction of 20% for dipping and alkalization , to become alkalized cellulose, wherein the mass volume ratio of carboxymethyl cellulose gauze to NaOH solution is 1g:16ml, and the soaking time is 30min. During dipping, a roller is used to repeatedly squeeze the gauze to ensure sufficient soaking and the absorption of alkali solution. The melting temperature is controlled at 20°C;

[0050] (2) Take out the alkalized cellulose from the alkalization tank, place it in a low-speed centrifuge for centrifugal pressing, remove excess lye, the mass ratio of alkalized cellulose before and after centrifugal pressing is 4:1, and chloroacetic ethanol The solution is placed in an etherification reaction tank, wherein the mass ratio of chloroacetic acid to alkalized cellul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com