Preparation method of polymer particles with wrinkling surfaces

A technology of polymers and particles, which is applied in the field of preparation of surface wrinkled polymer particles, can solve problems such as difficult to remove, affect the performance of polymers, and easy aging of polymers, and achieve large shape controllability, low cost, Easy post-processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

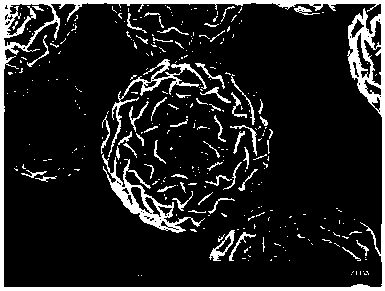

[0017] Example 1: Polyglycidyl methacrylate initiates polymerization of ethylene glycol dimethacrylate to prepare surface wrinkled polymer particles

[0018] Mix 6g of polyglycidyl methacrylate, 40g of ethylene glycol dimethacrylate, and 100g of water, stir and emulsify at room temperature for 10 minutes, heat to 60°C, and react for 12 hours, then fully wash to remove unpolymerized dimethylformaldehyde Polyethylene glycol acrylate and polyglycidyl methacrylate dissolved in water to obtain polyethylene dimethacrylate surface wrinkled polymer particles.

Embodiment 2

[0019] Example 2: Polyglycidyl methacrylate initiates divinylbenzene polymerization to prepare surface wrinkled polymer particles

[0020] Mix 4g of polyglycidyl methacrylate, 40g of divinylbenzene monomer, and 100g of water, stir and emulsify at room temperature for 10 minutes, heat to 70°C, and react for 12 hours, then fully wash to remove unpolymerized divinylbenzene and polyglycidyl methacrylate dissolved in water to obtain polydivinylbenzene surface wrinkled polymer particles.

Embodiment 3

[0021] Example 3: Polyglycidyl methacrylate initiates bismaleimide polymerization to prepare surface wrinkled polymer particles

[0022] Mix 4g of polyglycidyl methacrylate, 40g of bismaleimide, and 100g of water, stir and emulsify at room temperature for 30 minutes, heat to 70°C, and react for 12 hours, then fully wash to remove unpolymerized bismaleimide imine and polyglycidyl methacrylate dissolved in water to obtain polybismaleimide surface wrinkled polymer particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com