Method for increasing PHA yield by inhibiting halophilic archaea EPS yield

A technology for improving production and halophilic archaea, which is applied in the field of microbial fermentation to produce polymers, can solve the problems of high cost of recombinant strains, difficult engineering implementation, and complicated operation, so as to control fermentation costs, reduce sterilization costs, and simplify sterilization. The effect of the bacterial process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

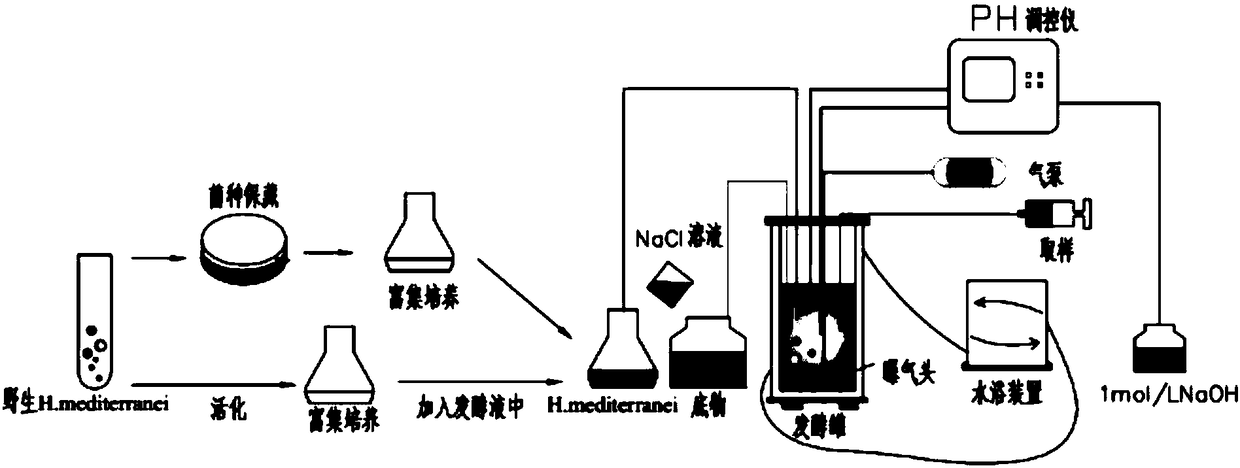

Method used

Image

Examples

Embodiment 1

[0037] In the embodiment, the strain used is Haloferax mediterranei, strain number ATCC 33500.

[0038] The seed medium of the strain contains: 7.5g of peptone per 1L of deionized water, 10g of yeast extract, 3g of sodium citrate, 20g of magnesium sulfate, 2g of potassium chloride, 0.01g of ferrous ion, and 200g of sodium chloride. And adjust the pH to 7.2.

[0039] The medium formula for fermentation is 200g of sodium chloride, 10g of glucose, 0.48g of ammonium chloride, 13g of magnesium chloride hexahydrate, 0.69g of calcium chloride dihydrate, 20g of magnesium sulfate heptahydrate, 4g of potassium chloride, and hydrogen carbonate per 1L of distilled water. Sodium 0.25g, sodium bromide 0.5g, potassium dihydrogen phosphate 0.439g, trace element solution 1ml (trace element solution is prepared by a known method, every 100ml of trace element solution contains zinc sulfate heptahydrate 0.1g, magnesium chloride tetrahydrate 0.03g, boric acid 0.3g, cobalt chloride hexahydrate 0.2...

Embodiment 2

[0046] In the embodiment, the strain used is Haloferax mediterranei, strain number ATCC 33500.

[0047] The seed medium of the strain contains: 7.5g of peptone per 1L of deionized water, 10g of yeast extract, 3g of sodium citrate, 20g of magnesium sulfate, 2g of potassium chloride, 0.01g of ferrous ion, and 200g of sodium chloride. And adjust the pH to 7.2.

[0048] The medium formula for fermentation is 250g of sodium chloride, 10g of glucose, 0.48g of ammonium chloride, 13g of magnesium chloride hexahydrate, 0.69g of calcium chloride dihydrate, 20g of magnesium sulfate heptahydrate, 4g of potassium chloride, and hydrogen carbonate per 1L of distilled water. Sodium 0.25g, sodium bromide 0.5g, potassium dihydrogen phosphate 0.439g, trace element solution 1ml (trace element solution is prepared by a known method, every 100ml of trace element solution contains zinc sulfate heptahydrate 0.1g, magnesium chloride tetrahydrate 0.03g, boric acid 0.3g, cobalt chloride hexahydrate 0.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com