Fuel battery catalyst modified by metal-organic framework and preparation method

An organic framework and fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor anti-toxicity, high price, and CO poisoning, and achieve reduced modification costs, reduced dependence, and excellent catalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

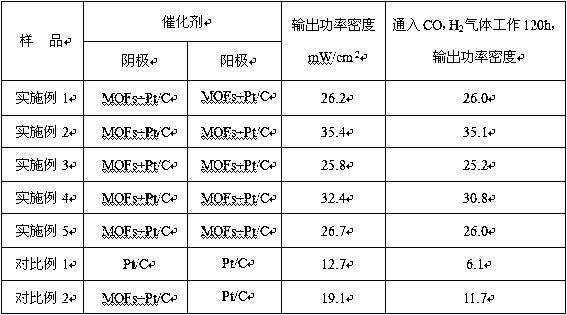

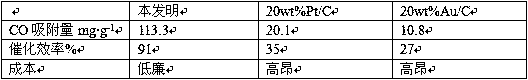

Examples

Embodiment 1

[0033] (1) Mix 3 parts of iron powder with 20 parts of nitric acid in parts by weight. After the iron powder is completely dissolved, add 2 parts of benzoic acid and 1 part of hydrofluoric acid, stir evenly and carry out hydrothermal treatment. The hydrothermal temperature is controlled at 98°C , after centrifugation and precipitation, the speed of centrifugation is controlled at 500rpm, the precipitation is filtered out, and then freeze-dried, the treatment temperature of freeze-drying is -40°C, and the air pressure is controlled at 700Pa to obtain metal-organic framework crystal materials;

[0034](2) adding the metal-organic framework crystal material into a dry-process ball mill, the media balls of the ball mill are corundum media, the speed of the ball mill is controlled at 800 rpm, and the ball mill is pulverized to obtain a metal-organic framework powder with a particle size of 300 μm and a skeleton structure;

[0035] (3) Coat the first surface of the carbon fiber layer...

Embodiment 2

[0038] (1) Mix 7 parts of iron powder with 18 parts of nitric acid in parts by weight. After the iron powder is completely dissolved, add 2 parts of phthalic acid and 1 part of hydrofluoric acid, stir well and then carry out hydrothermal treatment. The hydrothermal temperature is controlled at 85 ℃, after centrifugation and precipitation, the speed of centrifugation is controlled at 2000rpm, the precipitation is filtered out, and then freeze-dried, the treatment temperature of freeze-drying is -34℃, the air pressure is controlled at 10Pa, and the metal-organic framework crystal material is obtained;

[0039] (2) adding the metal-organic framework crystal material into a dry-process ball mill, the media balls of the ball mill are corundum media, the speed of the ball mill is controlled at 800 rpm, and the ball mill is pulverized to obtain a metal-organic framework powder with a particle size of 120 μm and a skeleton structure;

[0040] (3) Coat the first surface of the carbon fi...

Embodiment 3

[0043] (1) Mix 5 parts of iron powder with 20 parts of nitric acid in parts by weight. After the iron powder is completely dissolved, add 3 parts of phenylacetic acid and 1 part of hydrofluoric acid, stir well and then carry out hydrothermal treatment. The temperature of the hydrothermal treatment is controlled at 88°C , after centrifugation and precipitation, the speed of centrifugation is controlled at 1300rpm, the precipitation is filtered out, and then freeze-dried, the treatment temperature of freeze-drying is -20°C, and the air pressure is controlled at 10Pa to obtain metal-organic framework crystal materials;

[0044] (2) adding the metal-organic framework crystal material into a dry-process ball mill, the media balls for ball milling are corundum media, and the speed of the ball mill is controlled at 2000rpm to obtain a metal-organic framework powder with a particle size of 100 μm and a skeleton structure;

[0045] (3) Coat the first surface of the carbon fiber layer wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com