Processing equipment and method of multi-layer parquet for floor heating

A technology of solid wood composite flooring and processing equipment, which is applied in the direction of wood processing equipment, the joining of wooden veneers, chemical instruments and methods, etc., and can solve the problems of increased formaldehyde emission, poor thermal conductivity, and affecting the scope of application. Achieve the effect of reducing formaldehyde release, reducing dosage and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

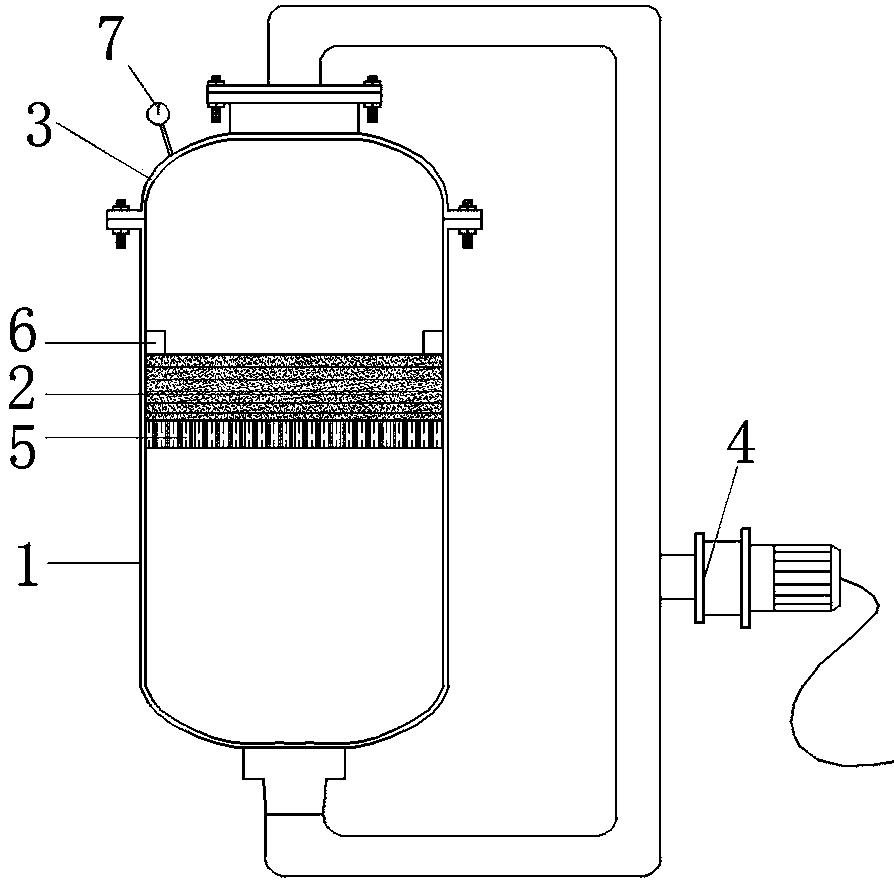

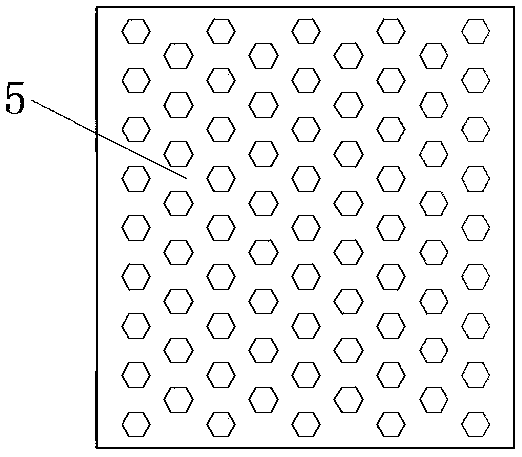

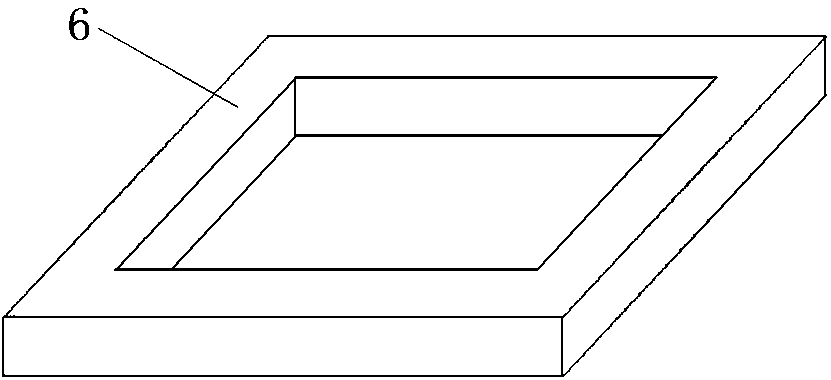

[0031] Such as Figure 1-3 As shown in the structural diagram of the processing equipment of this embodiment, the sealed container (1) is in the shape of a cuboid, and the size of the inner cavity is equal to that of the plate (2). The width of the inner cavity is 1800 mm, and the length is 2200 mm. There is a sealing cover (3) on the top, and a fixing plate (5) densely covered with microholes is arranged in the middle, and the diameter of the microholes is 4mm. A circulating pump (4) is connected between the upper and lower sides of the sealed container through the impregnating liquid pipeline; multiple layers of plates to be impregnated are stacked above the fixed plate, and a pressure ring (6) is arranged on the upper periphery of the plates to be impregnated.

[0032] The specific processing method is

[0033] (1) Preparation of impregnation solution: Take water, heat-conducting carbon fiber powder, alumina, and molybdenum disulfide powder, and mix them according to the m...

Embodiment 2

[0041] Such as Figure 1-3 As shown in the structural diagram of the processing equipment of this embodiment, the sealed container (1) is in the shape of a cuboid, and the size of the inner cavity is equal to that of the plate (2). The width of the inner cavity is 800 mm, and the length is 800 mm. There is a sealing cover (3) on the top, and a fixing plate (5) densely covered with micro-holes is arranged in the middle, and the diameter of the micro-holes is 2mm. A circulating pump (4) is connected between the upper and lower sides of the sealed container through the impregnating liquid pipeline; multiple layers of plates to be impregnated are stacked above the fixed plate, and a pressure ring (6) is arranged on the upper periphery of the plates to be impregnated.

[0042] The specific processing method is

[0043] (1) Preparation of impregnation solution: Take water, heat-conducting carbon fiber powder, alumina, and molybdenum disulfide powder, and mix them according to the m...

Embodiment 3

[0051] Such as Figure 1-3 As shown in the structural diagram of the processing equipment of this embodiment, the sealed container (1) is in the shape of a cuboid, and the size of the inner cavity is equal to that of the plate (2). The width of the inner cavity is 1350 mm, and the length is 1800 mm. There is a sealing cover (3) on the top, and a fixing plate (5) densely covered with micro-holes is arranged in the middle, and the diameter of the micro-holes is 3mm. A circulating pump (4) is connected between the upper and lower sides of the sealed container through the impregnating liquid pipeline; multiple layers of plates to be impregnated are stacked above the fixed plate, and a pressure ring (6) is arranged on the upper periphery of the plates to be impregnated.

[0052] The specific processing method is

[0053] (1) Preparation of impregnation solution: Take water, heat-conducting carbon fiber powder, alumina, and molybdenum disulfide powder, and mix them according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com