Preparation method of citral

A technology of citral and aldehyde diprenyl acetal, which is applied in the field of citral preparation, can solve the problems of long residence time, heavy component generation, and increased production energy consumption, so as to shorten the reaction time and make full use of energy , The effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

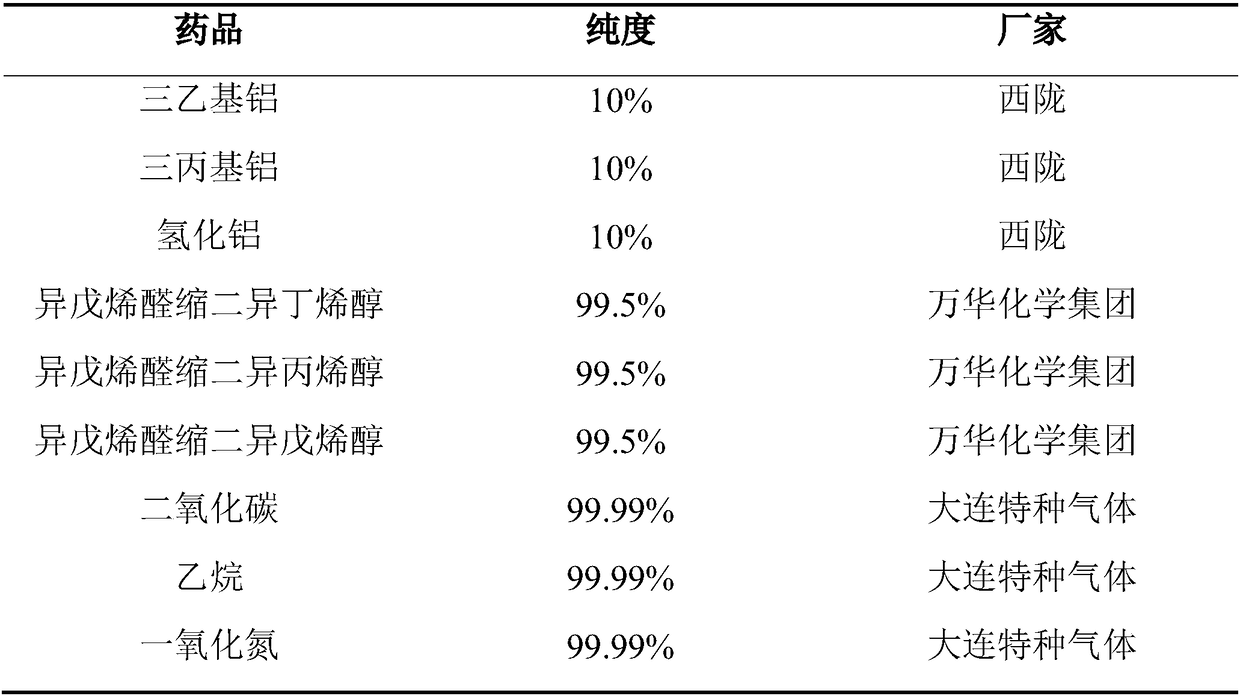

Embodiment 1

[0029] Add 0.0718g of triethylaluminum to the flash tank, raise the temperature of the flash tank to 150°C, replace it with 0.5MPa carbon dioxide gas for 5 times, then press the flash tank to 3MPa with carbon dioxide gas, and keep the pressure with the back pressure valve. Add 238g of prenyl diprenyl acetal to the autoclave, use 0.5MPa carbon dioxide gas to replace it 5 times, feed carbon dioxide into the autoclave until the absolute pressure reaches 8MPa and raise the temperature to 150°C to start thermal cracking Reaction, after reacting for 20 minutes, open the discharge port of the reactor, so that all the thermal cracking reaction products enter the flash tank through the mass flow meter, the flow rate is 30g / min, close the discharge port of the reactor after feeding, and start the rearrangement reaction Timing, after observing that there is no obvious fluctuation in the back pressure gauge of the flash tank, continue the reaction, and the total reaction time of flash evap...

Embodiment 2

[0032] Add 0.00714g of tripropylaluminum to the flash tank, raise the temperature of the flash tank to 120°C, replace it with 0.5MPa ethane gas for 5 times, then press the flash tank to 10MPa with ethane gas, and keep the pressure with the back pressure valve . Add 238g of prenyl diisopropenyl acetal into the autoclave, replace it with 0.5MPa ethane gas for 5 times, feed ethane into the autoclave until the absolute pressure reaches 0.5MPa and raise the temperature to 200°C, start Thermal cracking reaction, after reacting for 5 minutes, open the discharge port of the reactor, so that all the thermal cracking reaction products enter the flash tank through the mass flow meter, the flow rate is 30g / min, close the discharge port of the reactor after feeding, and start to re- Arrange the reaction timing, observe that there is no obvious fluctuation in the back pressure gauge of the flash tank, then continue the reaction, the total reaction time of flash evaporation and rearrangement...

Embodiment 3

[0035] Add 0.710g of aluminum hydride to the flash tank, raise the temperature of the flash tank to 180°C, replace it with 0.5MPa carbon dioxide gas for 5 times, then press the flash tank to 5MPa with carbon dioxide gas, and keep the pressure with the back pressure valve. Add 238g of prenyl diprenyl acetal to the autoclave, use 0.5MPa carbon dioxide gas to replace 5 times, pass carbon dioxide into the autoclave until the absolute pressure reaches 20MPa and raise the temperature to 120°C to start thermal cracking Reaction, after reacting for 40 minutes, open the discharge port of the reactor, so that all the thermal cracking reaction products enter the flash tank through the mass flow meter, the flow rate is 30g / min, close the discharge port of the reactor after feeding, and start the rearrangement reaction Timing, after observing that there is no obvious fluctuation in the back pressure gauge of the flash tank, continue the reaction, and the total reaction time of flash evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com