HCCI diesel engine fuel oil mist spray testing device

A test device, diesel engine technology, applied in the direction of fuel injection device, measurement device, engine test, etc., can solve problems such as difficulties, and achieve the effect of high injection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

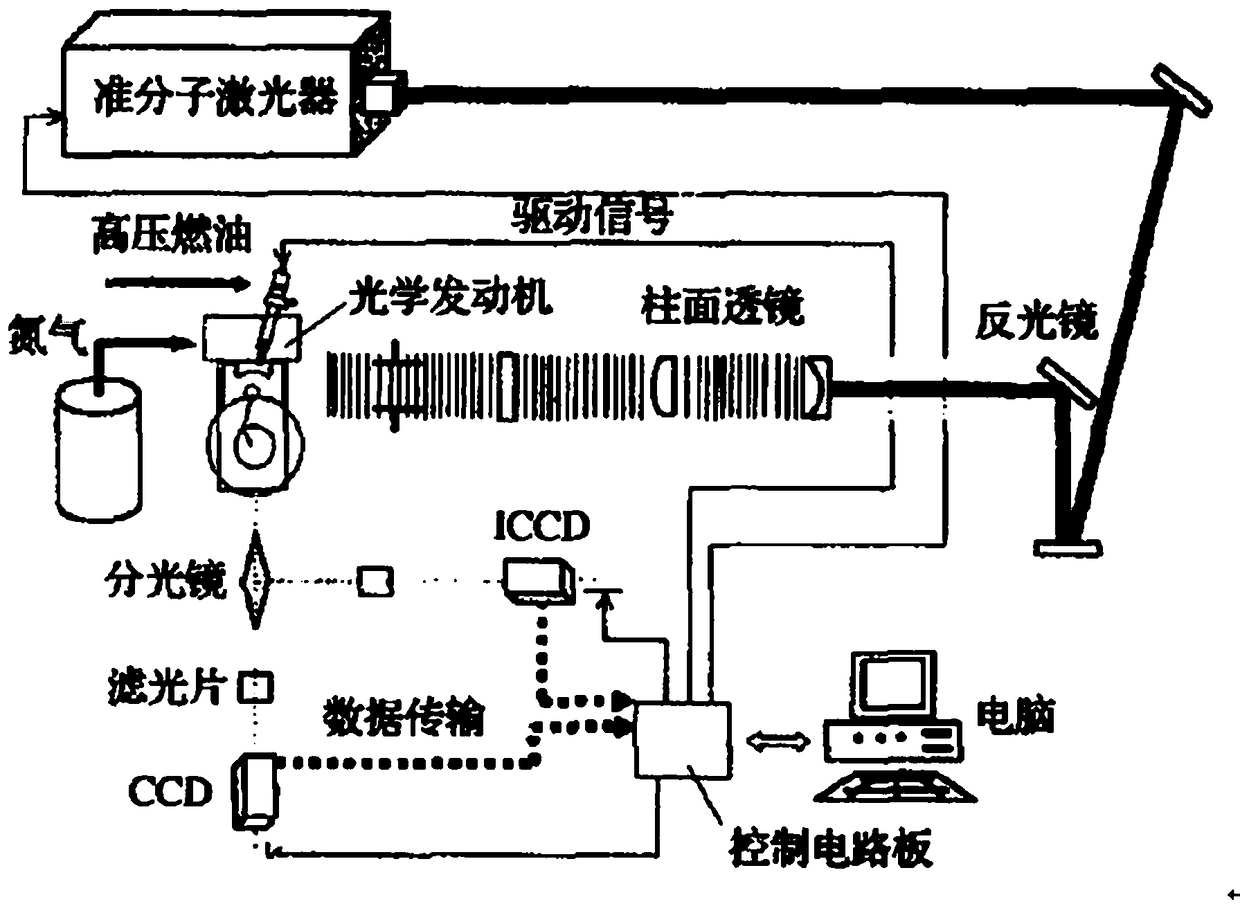

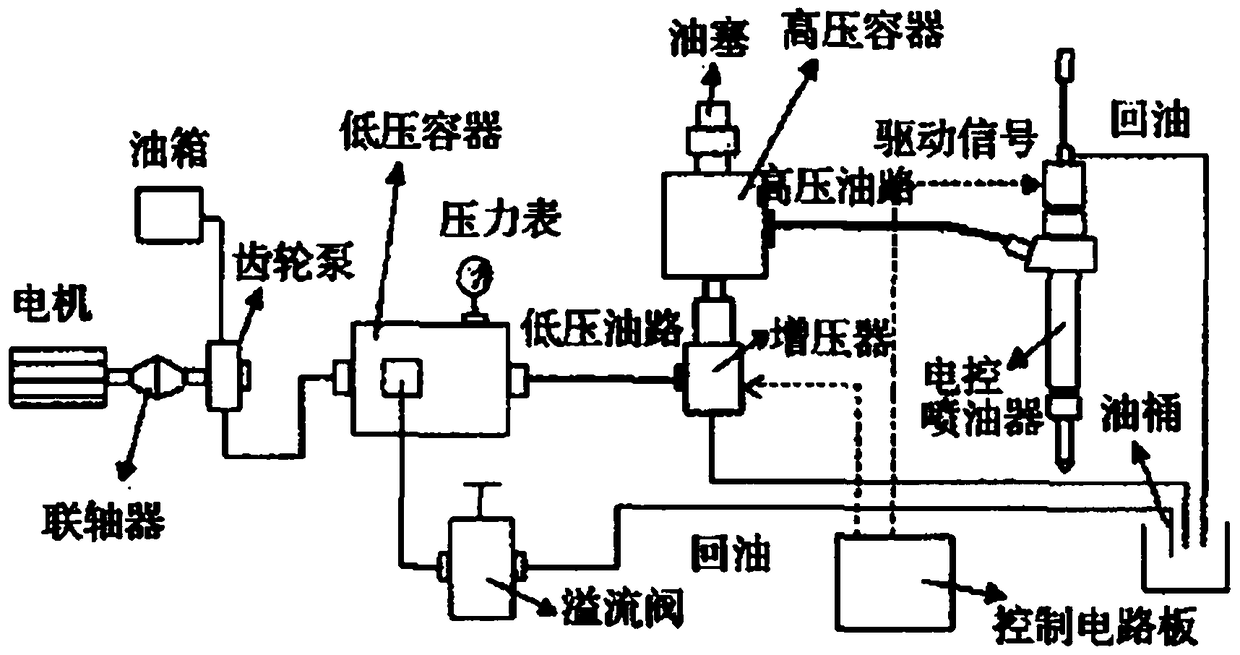

[0020] like figure 1 , in the experimental device of the laser-induced fluorescence test system based on high-voltage electronically controlled fuel injection, the test system consists of a laser and optical system, a visual engine dragged backwards by a motor, an engine intake system, a high-pressure fuel injection system and a control system based on a microcomputer. The system uses COMPex102 type excimer laser, the light source wavelength is 308nm. After the laser is reflected by the mirror, it is expanded, collimated and compressed to form a laser sheet, which is shot from the quartz window onto the spray oil beam in the cylinder of the visualized engine, and the fluorescent additive is excited to emit fluorescence.

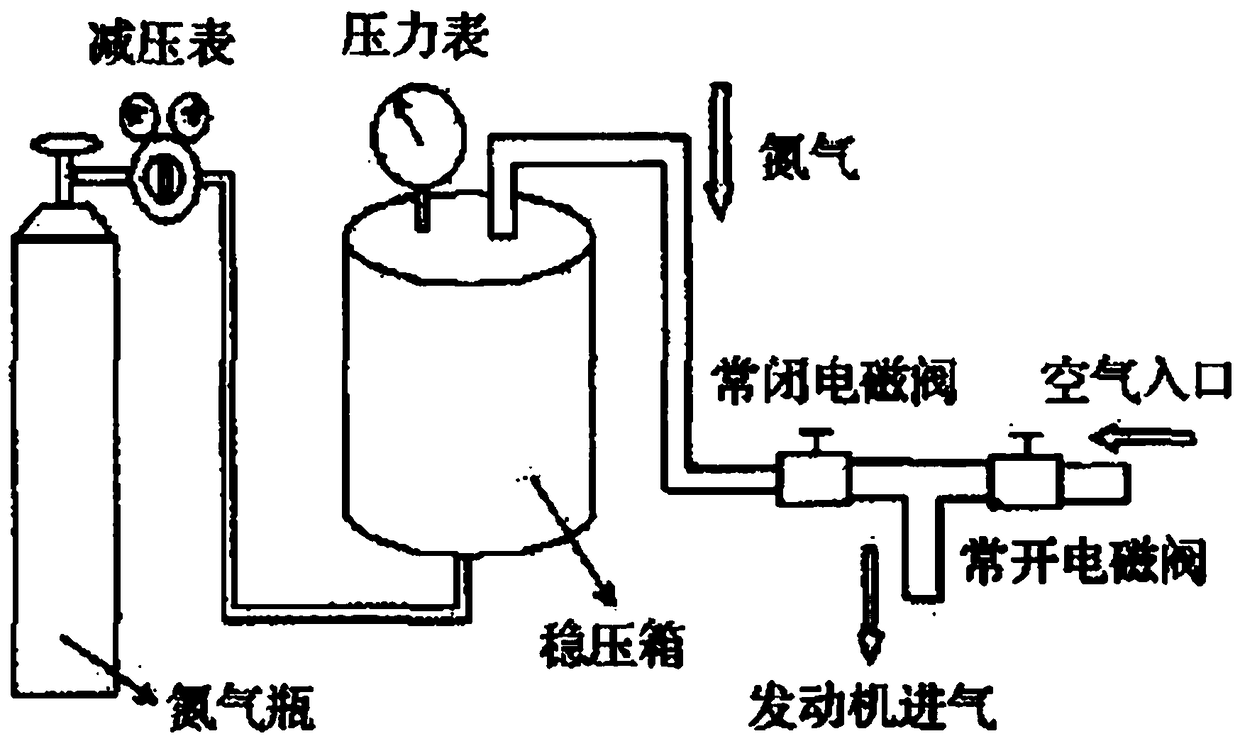

[0021] like figure 2 , The nitrogen supply system of the engine, the nitrogen is decompressed to roughly one atmospheric pressure by the pressure g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com