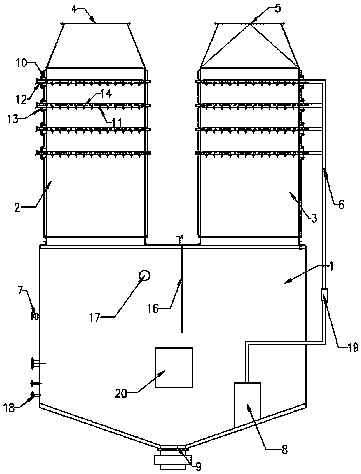

Hydrogen sulfide absorbing tower

An absorption tower, hydrogen sulfide technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of difficult maintenance, poor absorption effect, heavy equipment maintenance workload, etc., to ensure continuous operation and improve absorption. effect, the effect of reducing maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

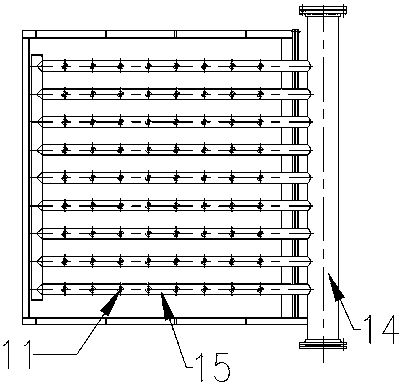

[0027] The present embodiment, as the best embodiment of the present invention, discloses a hydrogen sulfide absorption tower, comprising complex iron storage tank 1, the first spray tower 2 and the second spray tower 3, the first spray tower The tower 2 and the second spray tower 3 communicate with the complexed iron storage tank 1 at the same time, the top of the first spray tower 2 is provided with an air inlet 4, and the top of the first spray tower 2 is sequentially arranged from top to bottom There are 4 installation holes 10, and each installation hole 10 is provided with a spray branch pipe connected to the spray pipe 12, and the spray branch pipe is fixedly connected with the first spray tower through connecting bolts; 8 spray heads are provided; the top of the second spray tower is provided with an air outlet and a spray branch pipe and a spray head with the same structure as the first spray tower; on the side wall of the complex iron storage tank A feed inlet and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com