Chlorosilane liquid neutralization treatment device and treatment method

A processing device and liquid processing technology, applied in chemical instruments and methods, chemical/physical/physical-chemical processes, chemical/physical/physical-chemical stationary reactors, etc. problem, to achieve the effect of simple structure, reducing corrosion and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

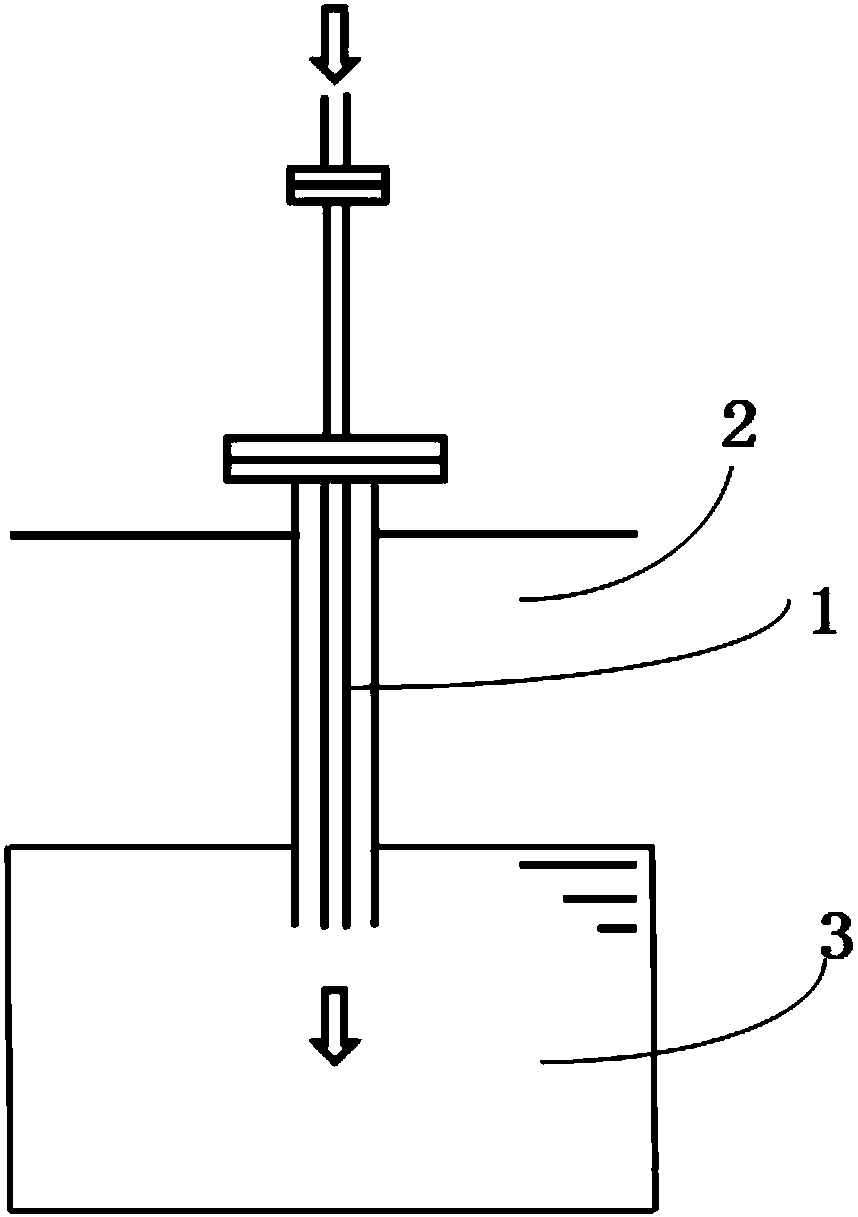

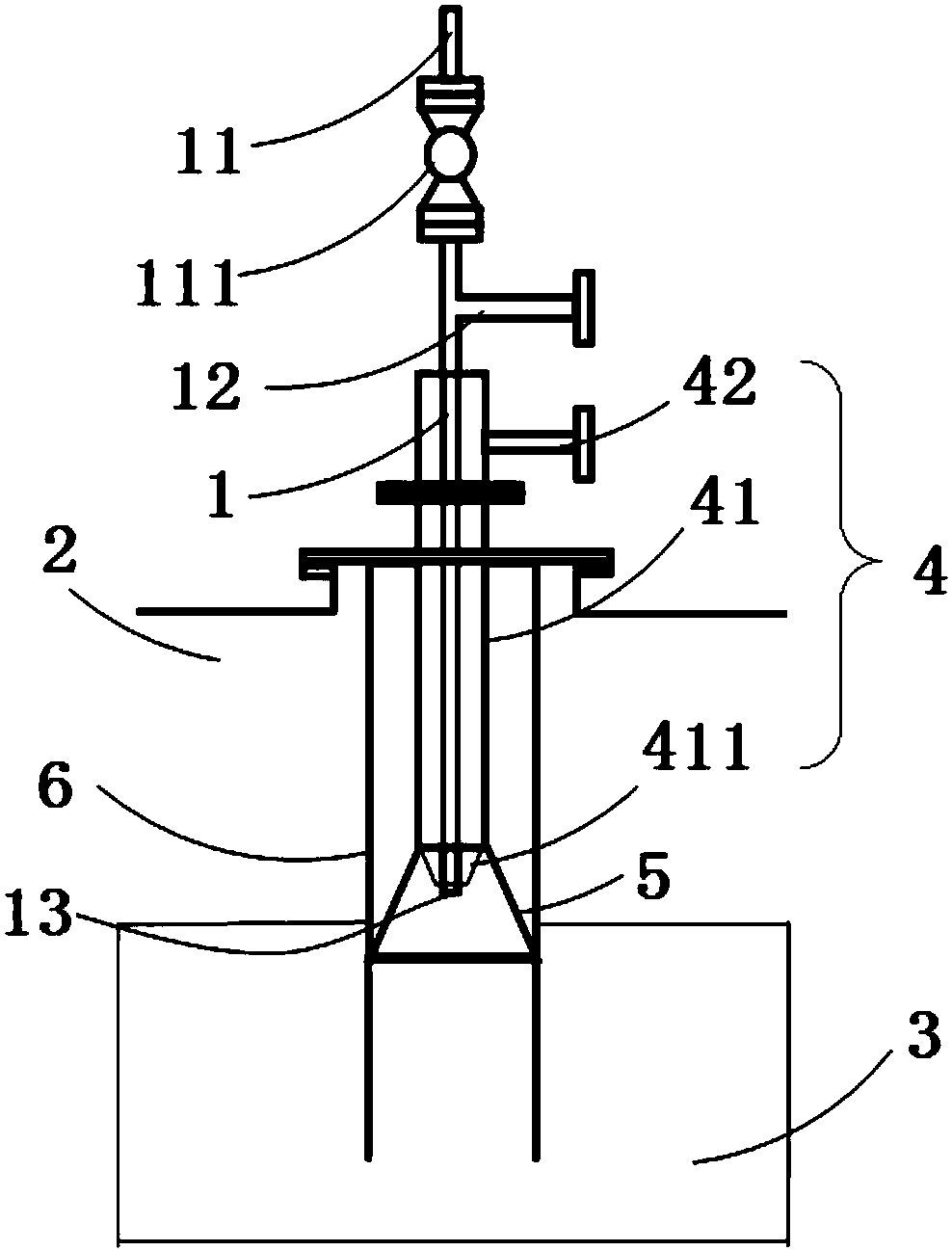

[0052] use as figure 2 The shown chlorosilane liquid neutralization treatment device performs neutralization treatment of chlorosilane liquid. The chlorosilane liquid used in this embodiment is the distillation residue of trichlorosilane synthesized by the reaction of metal silicon and hydrogen chloride (the content of silicon tetrachloride is 70% by mass; the solid content formed by metal chloride is 70% by mass. 2%), what is stored in the storage tank 2 is that the mass fraction is 10% sodium hydroxide aqueous solution.

[0053] The chlorosilane liquid supplied by the supply pipe 1 flows into the storage tank 2 along the liquid surface of the alkaline neutralizing liquid 3 to react with the alkaline neutralizing liquid 3, and the injection pipe 4 flows toward the liquid outlet Inert gas is sprayed around the side walls. Wherein, from the chlorosilane supply line 1, the amount per square meter (0.33L / second) of the liquid outlet 13 of the chlorosilane liquid supply pipe 1 ...

Embodiment example 2

[0058] In the modification example 1, the condition of supplying the above-mentioned chlorosilane liquid from the chlorosilane supply line 1 with the amount per square meter (0.33 L / sec) of the liquid outlet surface of the chlorosilane liquid supply pipe 1 is supplied, and at the same time, the injection pipe 4 Nitrogen gas in the gas is sprayed at the amount per square meter (0.72NL / second) of the gas outlet surface, and the supply rate relative to the above-mentioned chlorosilane liquid is 2.2NL / L, and the others are the same as the above-mentioned embodiment 1. Neutralization of chlorosilane liquids.

[0059] While replenishing the alkaline neutralizing solution 3 in the storage tank 2, the pH of the alkaline neutralizing solution 3 was controlled at 8 to 12, and the neutralization treatment was continued for 1 hour, but the liquid outflow from the chlorine supply pipe 1 did not occur. 13 clogging problems. After that, the neutralization treatment was carried out continuou...

comparative example 1

[0061] For Embodiment 1, the chlorosilane liquid was supplied from the chlorosilane supply line 1 while nitrogen gas was not injected from the injection pipe 4 , and the same neutralization treatment of the chlorosilane liquid was performed as in Embodiment 1 above.

[0062] While replenishing the alkaline neutralizing solution 3 in the storage tank 2, the pH of the alkaline neutralizing solution 3 was controlled at 8 to 12, and the neutralization treatment was carried out continuously for 1 hour, but the liquid outlet 13 of the chlorosilane supply line 1 A blockage has occurred at the end and processing cannot continue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com