Efficient adsorbent

An adsorbent, high-efficiency technology, applied in the fields of adsorption water/sewage treatment, inorganic chemistry, water/sludge/sewage treatment, etc. Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

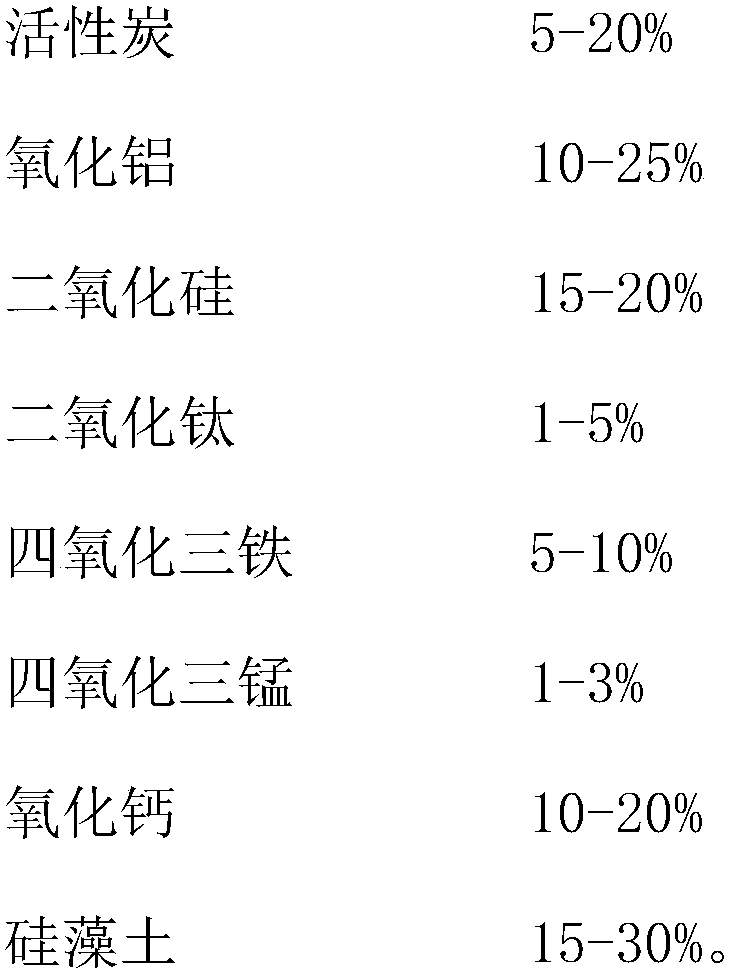

[0021] A high-efficiency adsorbent, which includes the following components by mass:

[0022]

[0023] The adsorbent has a core-shell structure. Alumina, silica, titanium dioxide, ferroferric oxide, manganese tetroxide and calcium oxide are all nanometers. The bulk density of diatomaceous earth is 0.29g / mL. The particle size is 18 microns, and its specific surface area is 53m 2 / g.

[0024] Mix and dissolve aluminum ammonium sulfate, titanium sulfate, ferrous sulfate and manganese sulfate to obtain a mixed solution, then add ammonium carbonate and ammonia water under stirring to control the pH of the solution to 9.9 and the reaction temperature to 39°C. The ammonium carbonate and the aluminum, The ratio of the total moles of titanium, ferrous iron and manganese is 2.5:1. After the reaction is completed, it is dried after washing, and then passed through a 90-mesh sieve. Then the dried material is added to the sodium silicate solution for slurrying. After finishing, add calcium chl...

Embodiment 2

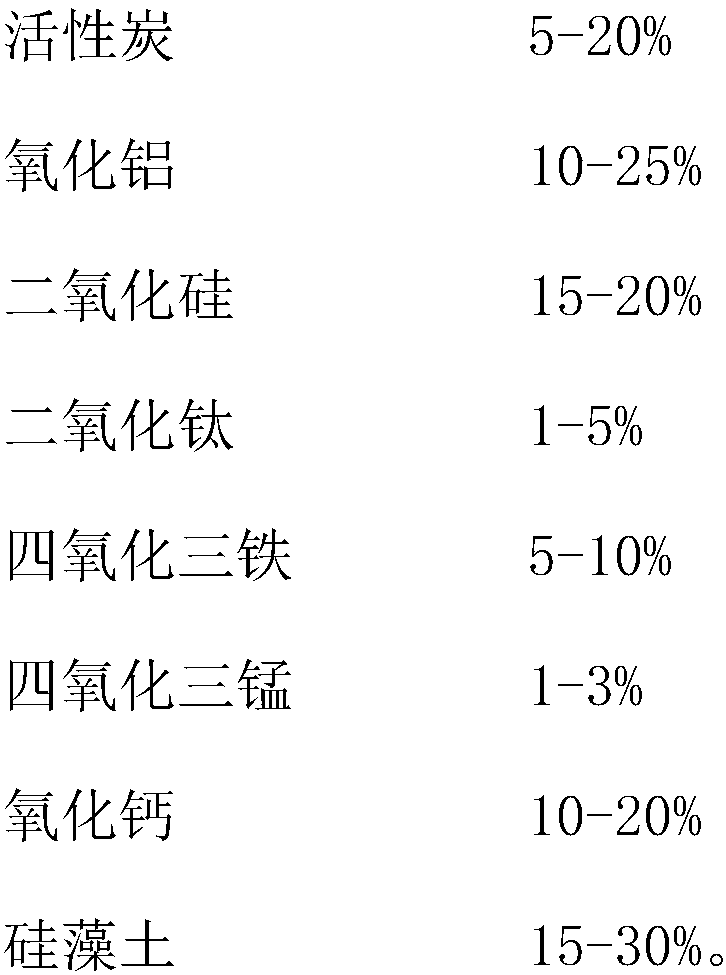

[0029] A high-efficiency adsorbent, which includes the following components by mass:

[0030]

[0031]

[0032] The adsorbent has a core-shell structure. Alumina, silica, titanium dioxide, ferroferric oxide, manganese tetroxide and calcium oxide are all nanometers. The bulk density of diatomaceous earth is 0.29g / mL. The particle size is 18 microns, and its specific surface area is 54m 2 / g.

[0033] Mix and dissolve aluminum ammonium sulfate, titanium sulfate, ferrous sulfate, and manganese sulfate to obtain a mixed solution, then add ammonium carbonate and ammonia water under stirring to control the pH of the solution to 10.2 and the reaction temperature to 42°C. The ammonium carbonate and the aluminum, The ratio of the total moles of titanium, ferrous iron and manganese is 2.8:1. After the reaction is completed, it is dried after washing, and then passed through a 100-mesh sieve, and then the dried material is added to the sodium silicate solution for slurrying. After finishing,...

Embodiment 3

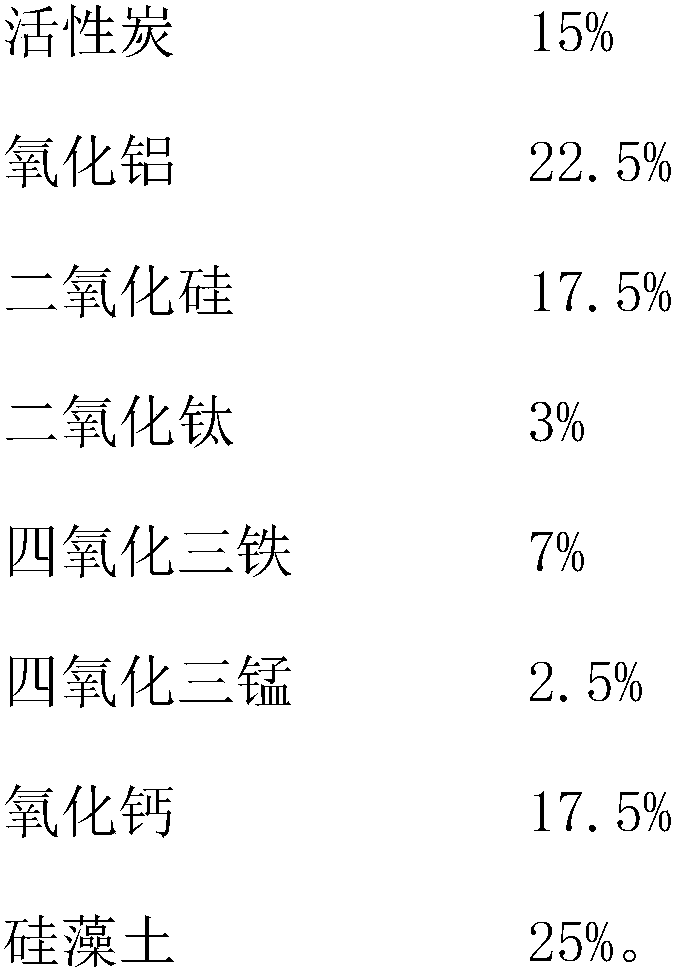

[0038] A high-efficiency adsorbent, which includes the following components by mass:

[0039]

[0040] The adsorbent has a core-shell structure. Alumina, silica, titanium dioxide, ferroferric oxide, manganese tetroxide and calcium oxide are all nanometers. The bulk density of diatomaceous earth is 0.31g / mL. The particle size is 18 microns, and its specific surface area is 57m 2 / g.

[0041] Mix and dissolve aluminum ammonium sulfate, titanium sulfate, ferrous sulfate and manganese sulfate to obtain a mixed solution, then add ammonium carbonate and ammonia water under stirring to control the pH of the solution to 10.25 and the reaction temperature to 38°C. The ammonium carbonate and the aluminum, The ratio of the total moles of titanium, ferrous iron and manganese is 2.8:1. After the reaction is complete, it is dried after washing, and then passed through a 90-mesh sieve, and then the dried materials are added to the sodium silicate solution for slurrying. After finishing, add calc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com