Perovskite quantum dot optical function board and preparation method thereof

An optical function, quantum dot technology, applied in chemical instruments and methods, luminescent materials, synthetic resin layered products, etc., can solve the problems of high assembly cost and single function, improve production controllability, simplify preparation methods, The effect of high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

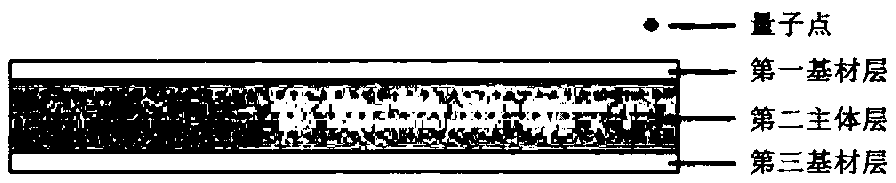

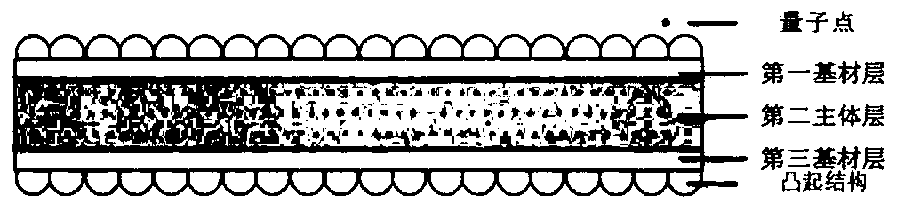

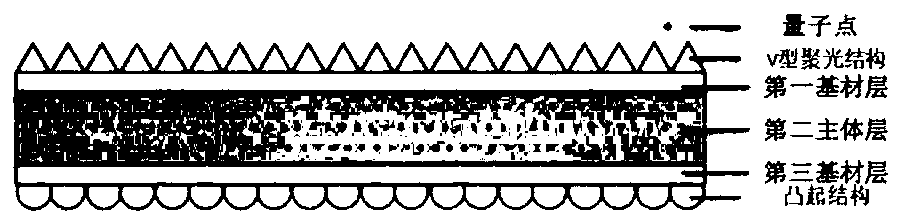

Embodiment 1

[0037] A perovskite quantum dot optical functional plate with a three-layer structure, the structure includes a first substrate layer, a second main body layer and a third substrate layer, and the main body layer is sandwiched between the first substrate layer and the third substrate layer between. The first base material layer is a thin layer made of an optical material with good adhesiveness and high light transmittance, and has good light transmittance, and the material of the third base material layer is a modified plastic with a relatively low melting point. The two base layers are extruded into a thin layer after the polymer particles are melted, and the thickness is less than 100 μm. The material can be polymethyl methacrylate (PMMA), polystyrene (PS), polycarbonate ( PC), polypropylene (PP) and other polymers or copolymers, the modification of materials is generally achieved by adding diffusing agents, UV absorbers, light stabilizers, antioxidants and other formulation...

Embodiment 2

[0042] The difference between the present embodiment and the first embodiment lies in that: the manufacturing method of the main functional layer of the quantum dot optical functional plate is different. The preparation method is as follows:

[0043] 1. Preparation of precursor solution: PbBr 2 (76.0 g, 0.207 mol) and CsBr (44.0 g, 0.207 mol) were dissolved in N,N - Dimethylformamide (DMF), then add 120 mL oleic acid and 60 mL oleylamine, stir and mix evenly to form a relatively stable precursor solution, ready for use;

[0044] 2. In situ synthesis of CsPbBr 3 Perovskite quantum dot optical function board: 20 kg polystyrene pellets ( M n = 82200 gmol -1 , M w = 212700 gmol -1 , M w / M n = 2.51), added to the hopper of the extruder, heated to 200 o C. After the polymer particles are in a molten flow state, argon gas is introduced to form a protective atmosphere, and the above precursor solution is added. Use the extruder screw to mix the system evenly, turn o...

Embodiment 3

[0046] The difference between this embodiment and Embodiment 1 is that the main functional layer of the quantum dot optical function board is prepared by first preparing quantum dot polymer particles in situ in a granulator, and then melt-extruding them in an extruder. Out into the board. The preparation method is as follows:

[0047] 1. Preparation of precursor cesium oleate: as described in Example 1;

[0048] 2. In situ synthesis of CsPbBr 3 Perovskite quantum dot polystyrene pellets: After the granulator is turned on and preheated, set the temperature from zone 1 to zone 10 of the granulator to 140~195 o C, membrane head and melt temperature set to 200 o C; 76.0 g lead bromide (PbBr 2 ), 60mL oleylamine mixed with 20 kg polystyrene pellets ( M n = 82200 gmol -1 , M w = 212700 gmol -1 , M w / M n = 2.51), feed the material at the feed port of the granulator, and inject argon gas to form a protective atmosphere. After setting the host speed, suction speed, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com