System and method for continuously preparing alcohol ethers by microwave catalysis

A microwave catalysis and alcohol ether technology, which is applied in the preparation of ether from alkylene oxide, ether preparation, organic chemistry, etc., can solve the problems of few catalyst active sites, low alcohol ether selectivity and yield, and unfavorable large-scale production, etc. Achieve the effect of shortening heat conduction time, improving production efficiency, and strengthening instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

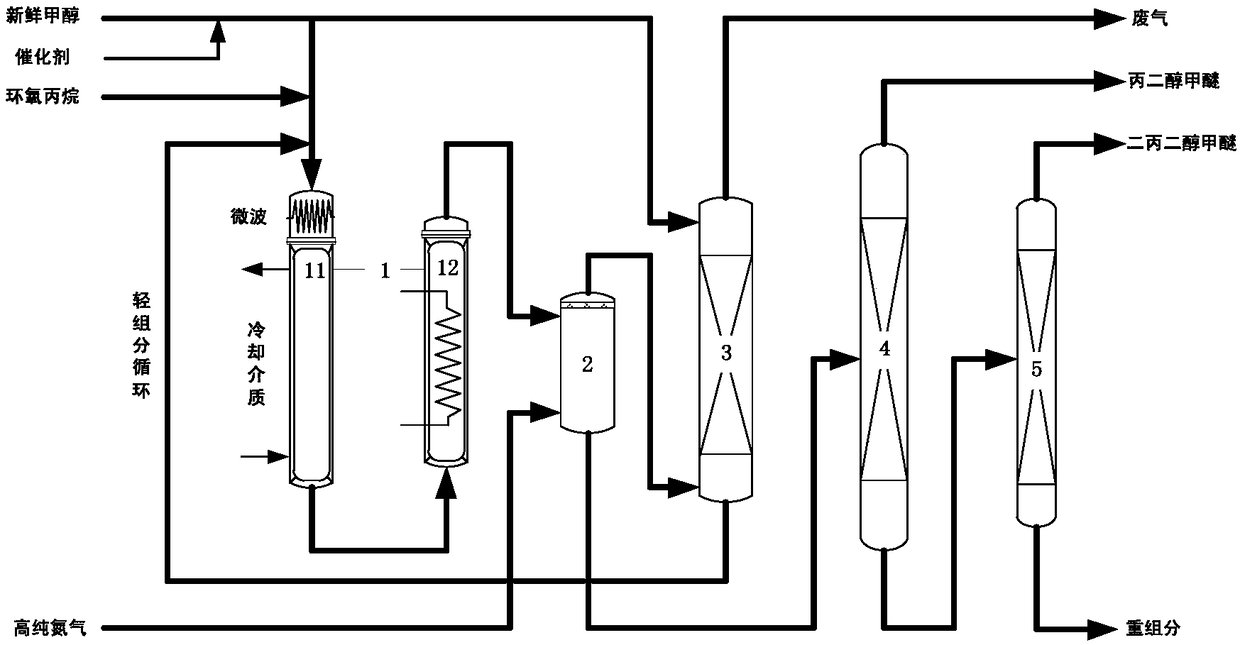

[0081] This embodiment provides a system for continuously preparing propylene glycol methyl ether by microwave catalysis, and its structural schematic diagram is as follows figure 1 As shown, the system includes a microwave reaction unit, an air stripping absorption unit and a product refining unit connected in sequence.

[0082] Described microwave reaction unit comprises microwave reactor 1, and described stripping absorption unit comprises interconnected stripping tower 2 and absorption tower 3; The outlet of the top of the stripper 2 is connected with the feed inlet of the absorption tower 3, the outlet of the bottom of the stripper 2 is connected with the product refining unit, and the outlet of the absorption tower 3 It is connected with the feeding port of microwave reactor 1.

[0083] Described microwave reactor 1 comprises primary microwave reactor 11 and secondary microwave reactor 12, and the bottom discharge port of described primary microwave reactor 11 is connec...

Embodiment 2

[0087] This embodiment provides a system for continuously preparing propylene glycol methyl ether by microwave catalysis, and the system includes a microwave reaction unit, an air stripping absorption unit and a product refining unit connected in sequence.

[0088] Described microwave reaction unit comprises microwave reactor 1, and described stripping absorption unit comprises interconnected stripping tower 2 and absorption tower 3; The outlet of the top of the stripper 2 is connected with the feed inlet of the absorption tower 3, the outlet of the bottom of the stripper 2 is connected with the product refining unit, and the outlet of the absorption tower 3 It is connected with the feed inlet of the microwave reactor 1, and the pipeline of the mixing feed inlet of the microwave reactor 1 is respectively connected with the feed pipeline of propylene oxide, the feed pipeline of methanol and the circulation pipeline of light components.

[0089] A microwave device is arranged in...

Embodiment 3

[0092] This embodiment provides a system for continuously preparing ethylene glycol methyl ether by microwave catalysis, the system includes a microwave reaction unit, an air stripping absorption unit and a product refining unit connected in sequence.

[0093] Described microwave reaction unit comprises microwave reactor 1, and described stripping absorption unit comprises interconnected stripping tower 2 and absorption tower 3; The outlet of the top of the stripper 2 is connected with the feed inlet of the absorption tower 3, the outlet of the bottom of the stripper 2 is connected with the product refining unit, and the outlet of the absorption tower 3 It is connected with the feeding port of microwave reactor 1.

[0094] Described microwave reactor 1 comprises primary microwave reactor 11 and secondary microwave reactor 12, and the bottom discharge port of described primary microwave reactor 11 is connected with the inlet of secondary microwave reactor 12, and described seco...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap