Antioxidant active peptide fragment derived from sea cucumbers and extraction method

A technology of antioxidant active peptides and antioxidant activities, which is applied in the field of preparation and identification of antioxidant active peptides, can solve the problems of unfavorable absorption, etc., and achieve the effect of strong antioxidant activity and clear sequence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

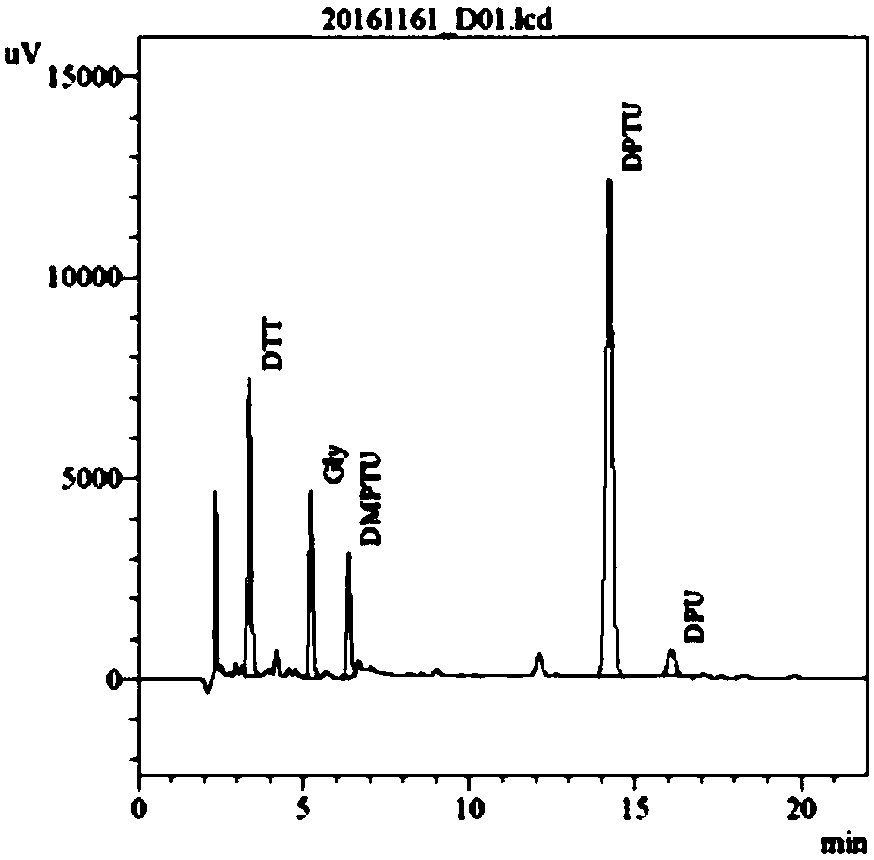

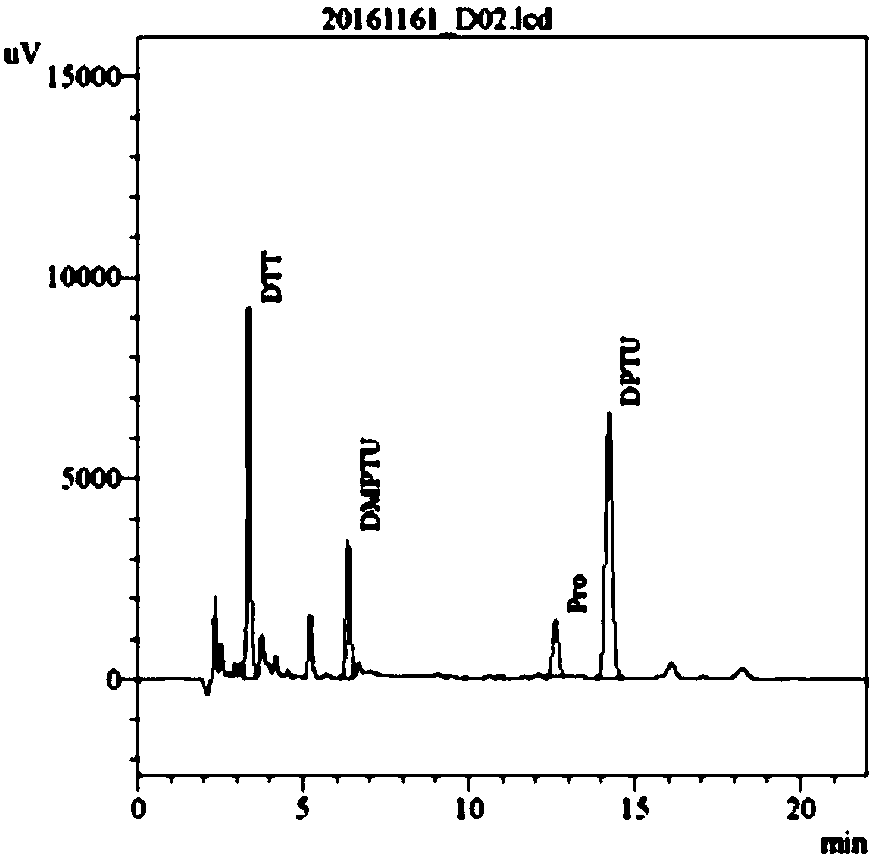

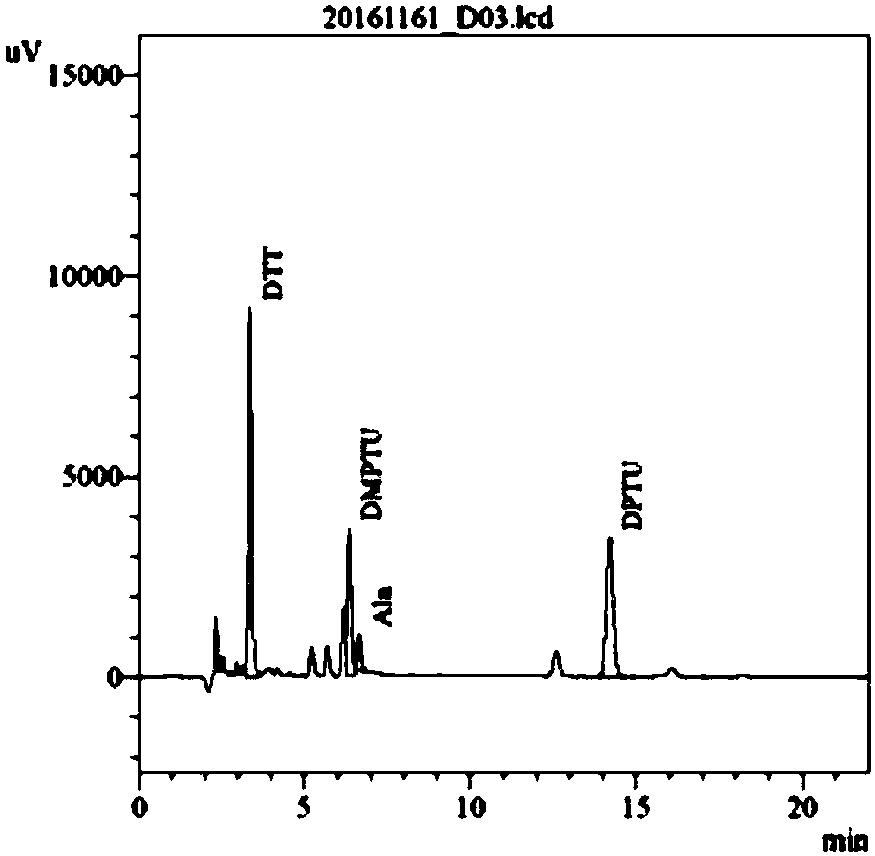

Image

Examples

Embodiment 1

[0034] A peptide with antioxidant activity derived from sea cucumber, the amino acid sequence of the peptide is NH 2 -Gly-Pro-Ala-Gly-Pro-Cys. The peptide has a good scavenging effect on DPPH free radicals, hydroxyl free radicals and superoxide anion free radicals.

Embodiment 2

[0036] A method for extracting antioxidant active peptides derived from sea cucumbers described in Example 1, specifically comprising the following steps:

[0037] S1, raw material pretreatment: 1000 kg of imitation sea cucumber body wall is pulverized with a meat grinder for 15 minutes, and then entered into a colloid mill for grinding to obtain a slurry;

[0038] S2, import the slurry into 5m 3 Enzymolysis tank, the 5m 3 The enzymolysis tank is a sandwich type heating reaction kettle, add pure water 3 times the mass of oyster slurry, adjust the system temperature to 50°C, adjust the pH to 8.6 with 2.5mol / L NaOH solution, add 0.12% of the total mass of the imitation sea cucumber slurry The compound protease of compound protease; the mass ratio of compound protease is: neutral protease: papain: flavor protease=3:4:3; Stir enzymolysis 4h, heat up 80 ℃ and kill enzyme 20min, adopt tubular centrifuge 16000rpm centrifugation to carry out solid-liquid Separation, collection of ce...

Embodiment 3

[0047] The extraction method of the antioxidant active peptides derived from sea cucumbers described in this example is the same as that in Example 2, and the different technical parameters are:

[0048]1) In step S1, the body wall of the imitation sea cucumber was crushed with a meat grinder for 10 minutes;

[0049] 2) In step S2, add pure water twice the mass of the oyster slurry, adjust the system temperature to 40°C, adjust the pH to 8.0 with 2.5mol / L NaOH solution, and add a compound protease of 0.1% of the total mass of the japonicus japonicus slurry; compound The mass ratio of protease is: neutral protease: papain: flavor protease = 2:3:4; stir for 3 hours, heat up to 82°C to extinguish the enzyme for 10 minutes, and use a tubular centrifuge at 10,000rpm to separate the solid from the liquid;

[0050] 3) In step S3, the obtained clear liquid is separated by a nanofiltration membrane separation device with a cutting molecular weight of 2000Da to obtain the permeate;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com