A low-temperature catalytic decomposition of n 2 The preparation method of the porous nio nanosheet catalyst of o

A nano-sheet, low-temperature catalysis technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, separation method, etc., can solve the problem of high conversion rate temperature, achieve high catalytic activity, and facilitate industrialization Production and raw materials are cheap and easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

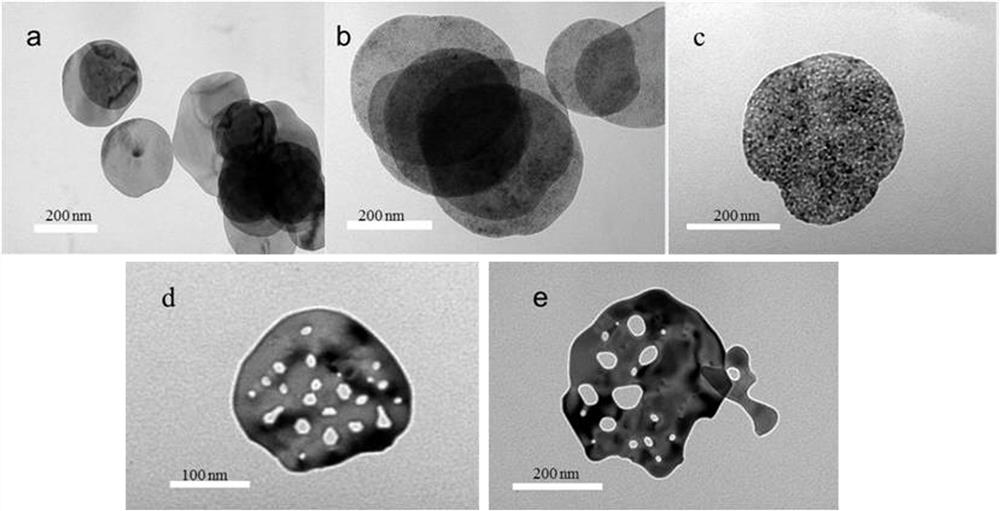

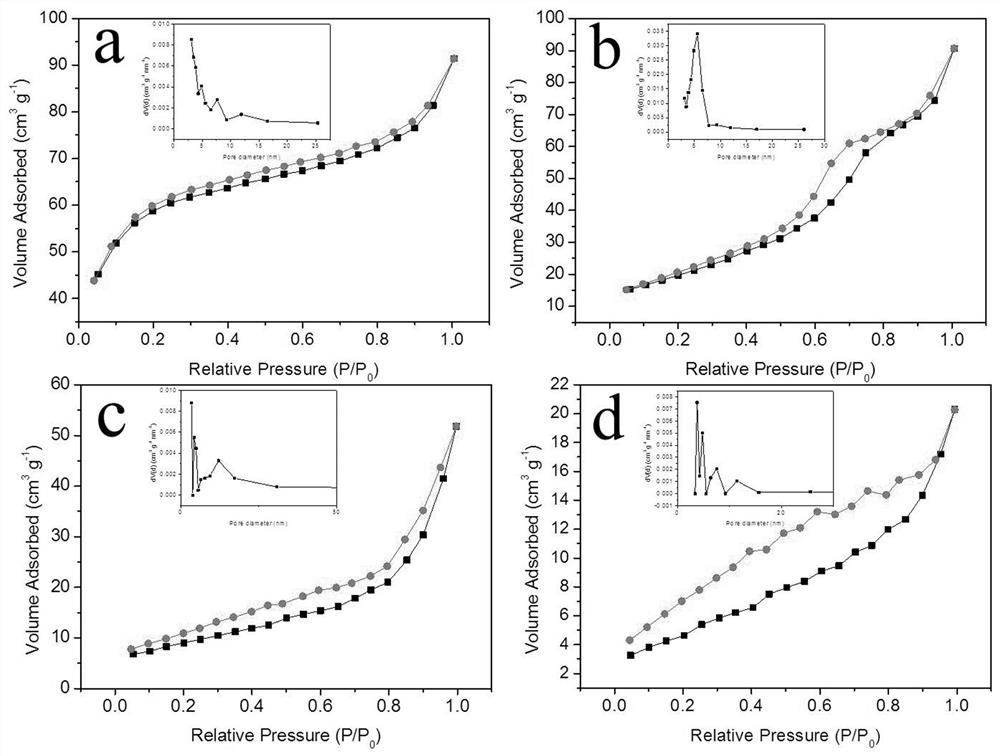

[0024] Weigh 1.18g NiCl 2 ·6H 2 O and 0.4g NaOH were completely dissolved in 10mL and 30mL deionized water respectively, and the obtained NaOH solution was added NiCl under stirring condition. 2 solution, transfer the mixed solution to a reaction kettle and seal it, place it in an electronic furnace and raise the temperature to 180°C for 10 hours. After the reaction is completed, cool it to room temperature, filter it with suction to obtain a green precipitate, and wash it several times with deionized water and absolute ethanol , placed in an oven and dried at 60°C to obtain a precursor, as attached figure 1 As shown in a, the dried precipitate was annealed in a quartz tube furnace at 300 °C for 2 hours, and the heating rate was 5 °C min -1 , as attached figure 1 As shown in b, the porous NiO nanosheet catalyst.

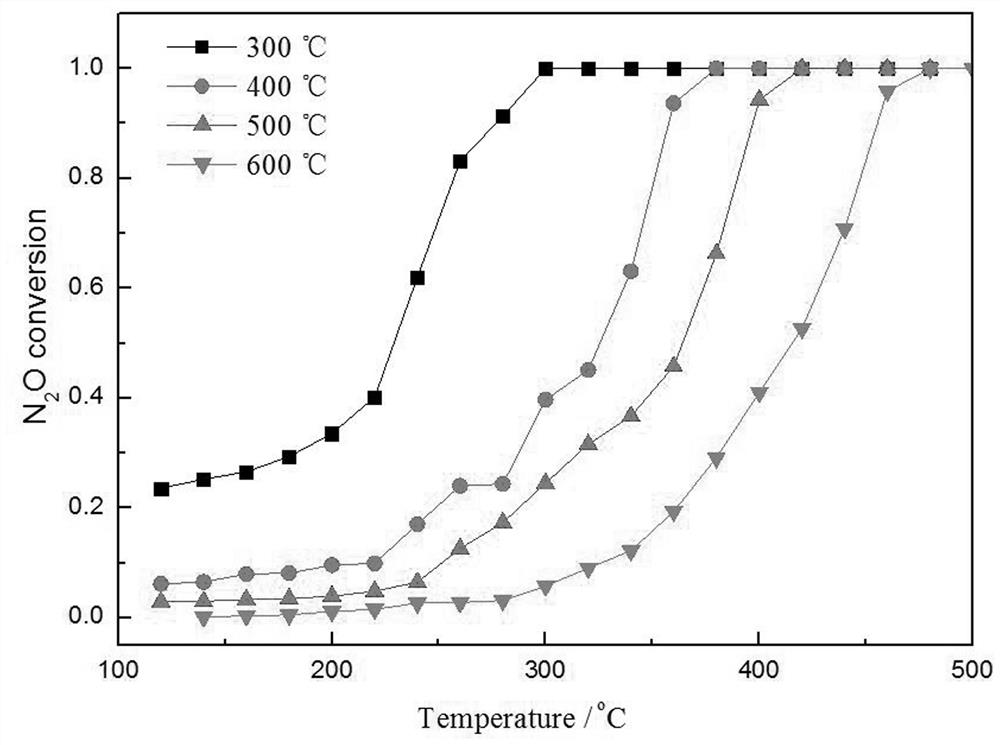

[0025] Take 300 mg of the above catalyst and put it into the 8 mm quartz reaction tube of the continuous flow micro-reaction device, and feed N 2 The mixed gas ...

Embodiment example 2

[0027] The annealing temperature in Example 1 was changed to 400°C.

[0028] Adopt embodiment 1 evaluation condition, under above-mentioned evaluation condition, obtain its specific surface area by attached table 1 and be 72m 2 g -1 , it can be seen from Figure 3 that when the catalytic temperature is 380°C, N 2 O conversion reaches 100%.

Embodiment 3

[0030] The annealing temperature in Example 1 was changed to 500°C.

[0031] Adopt embodiment 1 evaluation condition, under above-mentioned evaluation condition, obtain its specific surface area by attached table 1 and be 33m 2 g -1 , it can be seen from Figure 3 that when the catalytic temperature is 420°C, N 2 O conversion reaches 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com