Aerobic synchronous nitrification and denitrification biofilm process for treating nitrogen-polluted water

A simultaneous nitrification and biofilm technology, applied in the field of aerobic synchronous nitrification and denitrification biofilm treatment of nitrogen-polluted water bodies, can solve the problems of low-carbon source sewage denitrification, etc., to shorten the hydraulic retention time, shorten the start-up time, The effect of increasing the denitrification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

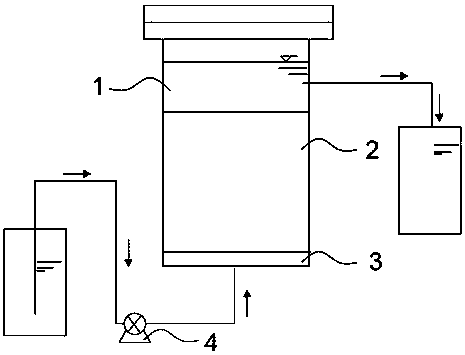

Image

Examples

Embodiment 1

[0036] An aerobic simultaneous nitrification and denitrification biofilm method to treat nitrogen-polluted water bodies: the simultaneous nitrification and denitrification biofilm is obtained by preparing a biofilm carrier; the biofilm carrier is 70% degradable fiber carrier and 30% modified mussel shell .

[0037] The preparation method of the biofilm carrier is to crush the agricultural waste containing more than 50% insoluble cellulose, immerse it in 1.0mol / L sodium hydroxide solution for 48 hours after passing through a 100-mesh sieve, wash until neutral, and add modified Mussel shell powder, mixed evenly and machined into a fixed shape.

[0038] The dosage of biofilm carrier is 20kg / m 3 , functional bacteria are added to the biofilm carrier, and the bottom of the biological aeration tank is aerated to supply oxygen to it, and the dissolved oxygen content in the water body is 6.0mg / L.

[0039] Use the concentration gradient change method to speed up the domestication of ...

Embodiment 2

[0050] An aerobic simultaneous nitrification and denitrification biofilm method to treat nitrogen-polluted water bodies: the simultaneous nitrification and denitrification biofilm is obtained by preparing a biofilm carrier; the biofilm carrier is 80% degradable fiber carrier and 20% modified mussel shell .

[0051] The preparation method of the biofilm carrier is to crush the agricultural waste containing more than 50% insoluble cellulose, immerse it in 1.0mol / L sodium hydroxide solution for 24 hours after passing through a 100-mesh sieve, wash until neutral, and add modified Mussel shell powder, mixed evenly and machined into a fixed shape.

[0052] The dosage of biofilm carrier is 20kg / m 3 , functional bacteria are added to the biofilm carrier, and the bottom of the biological aeration tank is aerated to supply oxygen to it, and the dissolved oxygen content in the water body is 6.0mg / L.

[0053] Use the concentration gradient change method to speed up the domestication of ...

Embodiment 3

[0064] An aerobic simultaneous nitrification and denitrification biofilm method to treat nitrogen-polluted water bodies: the simultaneous nitrification and denitrification biofilm is obtained by preparing a biofilm carrier; the biofilm carrier is 70% degradable fiber carrier and 30% modified mussel shell .

[0065] The preparation method of the biofilm carrier is to crush the agricultural waste containing more than 50% insoluble cellulose, immerse it in 1.0mol / L sodium hydroxide solution for 24 hours after passing through a 100-mesh sieve, wash until neutral, and add modified Mussel shell powder, mixed evenly and machined into a fixed shape.

[0066] The dosage of biofilm carrier is 20kg / m 3, functional bacteria are added to the biofilm carrier, and the bottom of the biological aeration tank is aerated to supply oxygen to it, and the dissolved oxygen content in the water body is 7.0mg / L.

[0067] Use the concentration gradient change method to speed up the domestication of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com