System used for pretreating crop straw

A crop straw and pretreatment technology is applied in the field of crop straw pretreatment system, which can solve the problems of reducing production efficiency, corrosion of acid on reaction vessel, pollution of reaction raw materials, etc., so as to save the space occupied by equipment and improve pretreatment efficiency. , Improve the effect of enzymatic hydrolysis and saccharification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

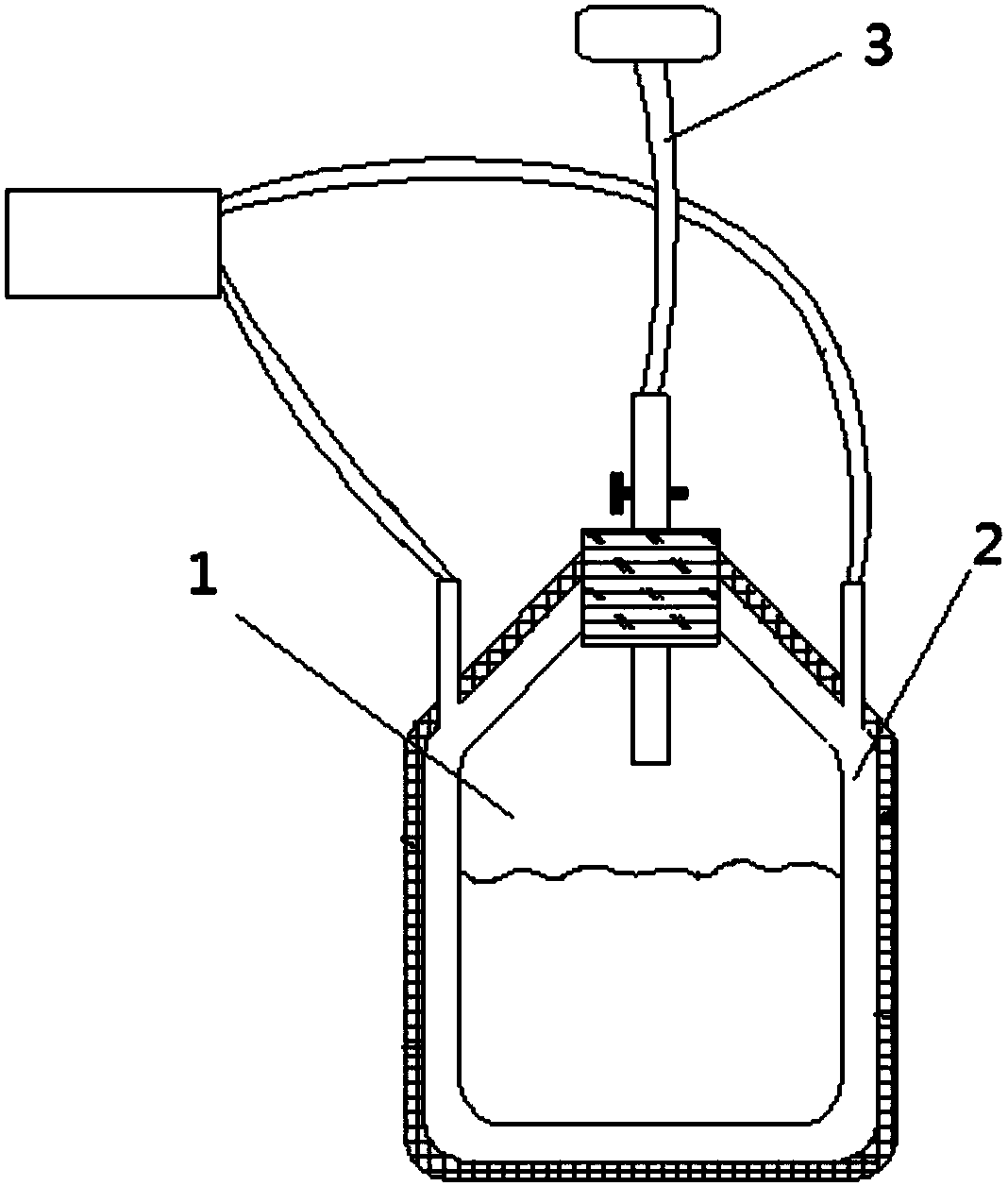

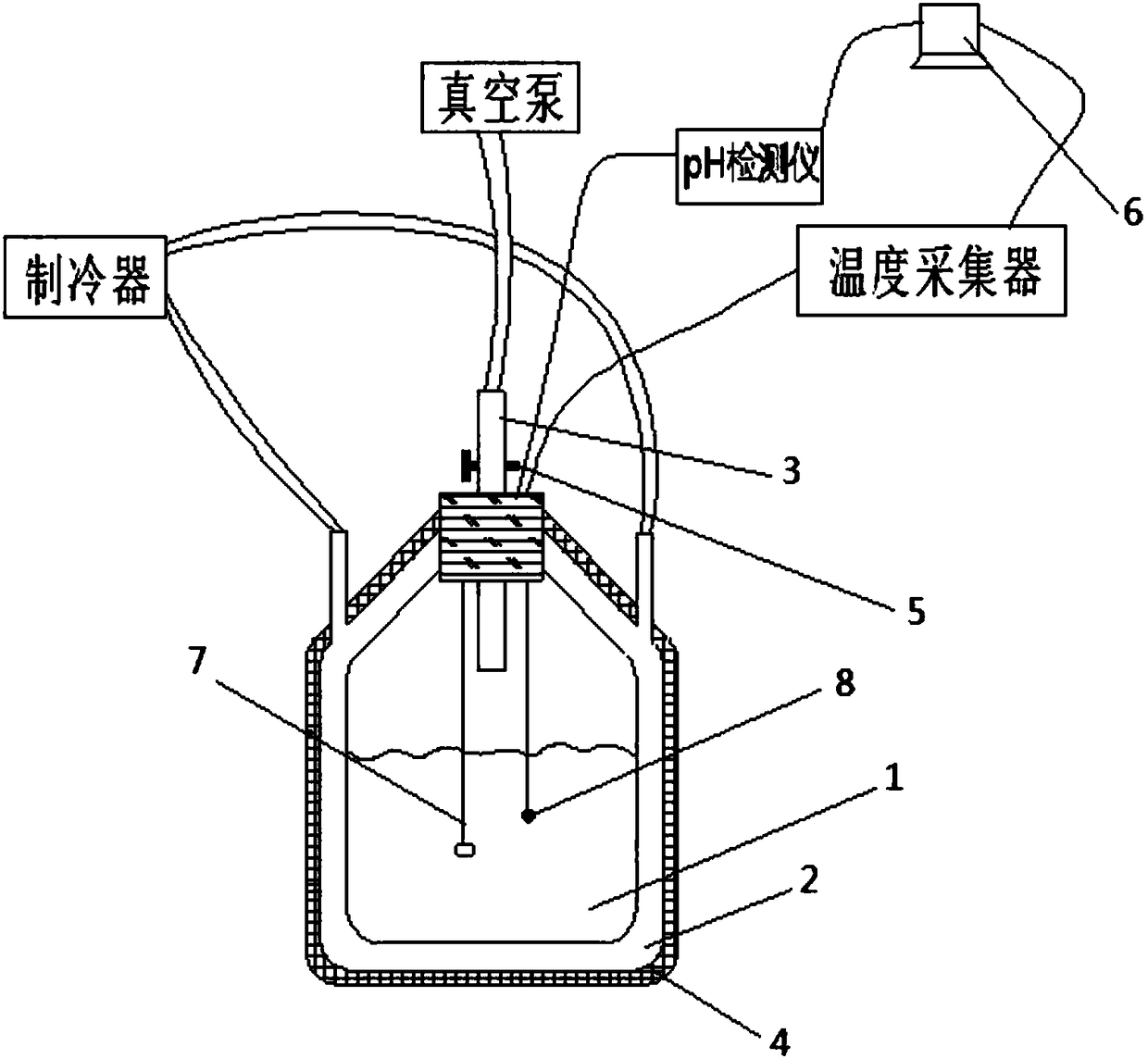

[0068] A system for pretreatment of crop stalks, such as figure 1 shown.

[0069] Including a reaction container, the reaction container includes a container body 1;

[0070] The outer wall of the container body 1 is covered with a heat exchange jacket 2;

[0071] The container body 1 is provided with a lye delivery pipe 3 .

[0072] The system works by:

[0073] Pass lye (slaked lime solution or sodium hydroxide solution etc.) Afterwards, the heat medium is continuously fed into the heat exchange jacket 2 until the frozen matter in the container melts, and after a period of reaction, the enzymatic hydrolysis process can be entered.

[0074] It can be seen that the system uses a combined method to pretreat straw, that is, freeze-thaw and alkali treatment are combined, and the two processes are carried out in the same container, that is, in-situ reaction, which saves the time spent on transferring the solution to the reaction container, so Improved processing efficiency. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com