Easy-to-dye sea island PTT filament and preparation method thereof

An island and filament technology, applied in filament/line forming, conjugated synthetic polymer rayon, stretch spinning, etc., can solve the problem of uneven color effect of fabrics, high difficulty in process control, and inconsistent dyeing grades. higher question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

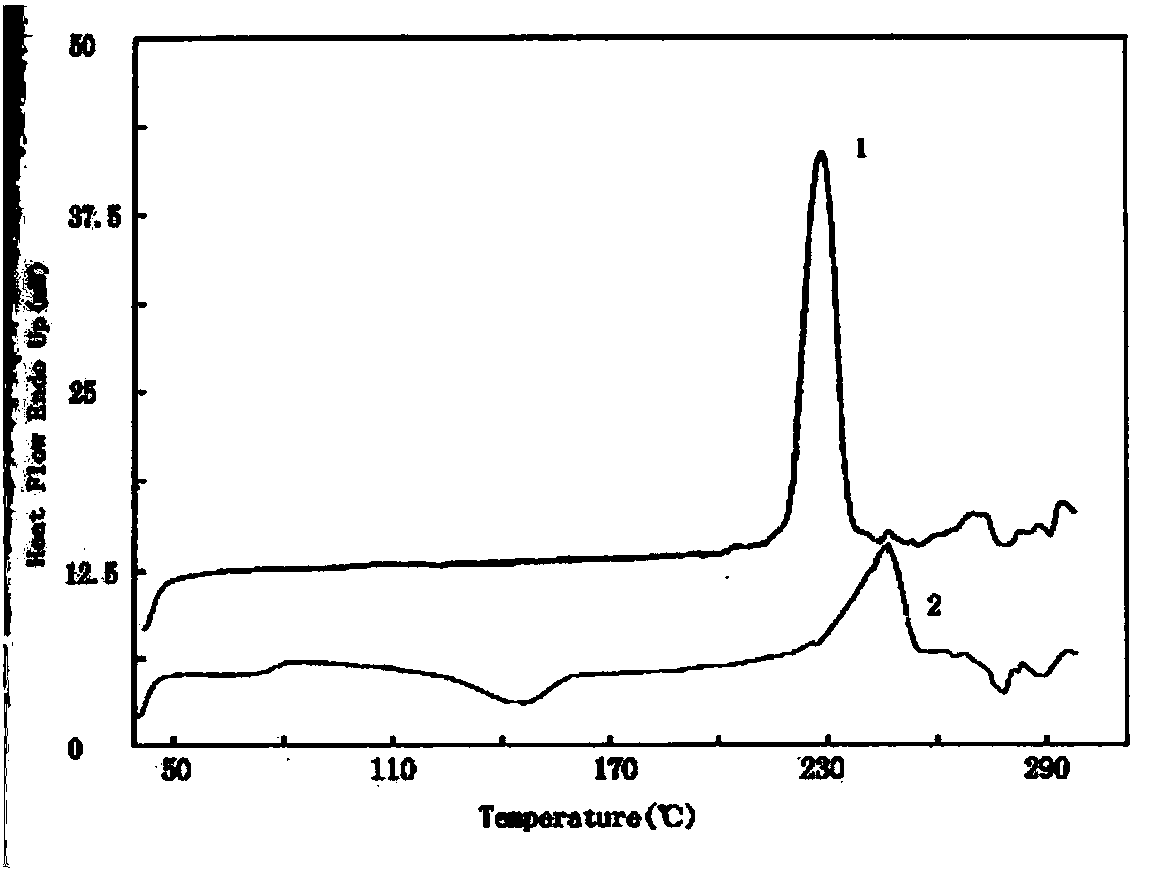

[0100] A sea-island PTT filament that is easy to dye: COPET slices are used as the sea component, and PTT slices and copolyamide masterbatch are used as the island component;

[0101] In the island component, the mass fraction of the copolyamide masterbatch to PTT is 2% to 8%;

[0102] Among them, the copolyamide is first polycondensed from dibasic acid and diamine to make polyamide, and then sulfonate is added to form copolyamide with sulfonic acid groups;

[0103] Wherein the polycondensation process is as follows, using purified terephthalic acid and hexamethylenediamine as basic raw materials, using phosphorous acid and triphenyl phosphate as catalysts, adding a small amount of antioxidant 1010, and pre-condensing, when the reaction reaches 2 hours At this time, from the perspective of stirring power, the viscosity of the system has increased, and at this time, three monomers of bishydroxyethyl isophthalate-5-sodium sulfonate (SIPE) are added. Its reaction formula can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com