Preparation method and application of water-soluble SnO2 inorganic semiconductor nanomaterial

A technology of inorganic semiconductors and nanomaterials, applied in the direction of organic semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of no further exploration of SnO dispersion ability, no further exploration of dispersion effect, unfavorable practical applications, etc., to achieve Good practical application value, good dispersion effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

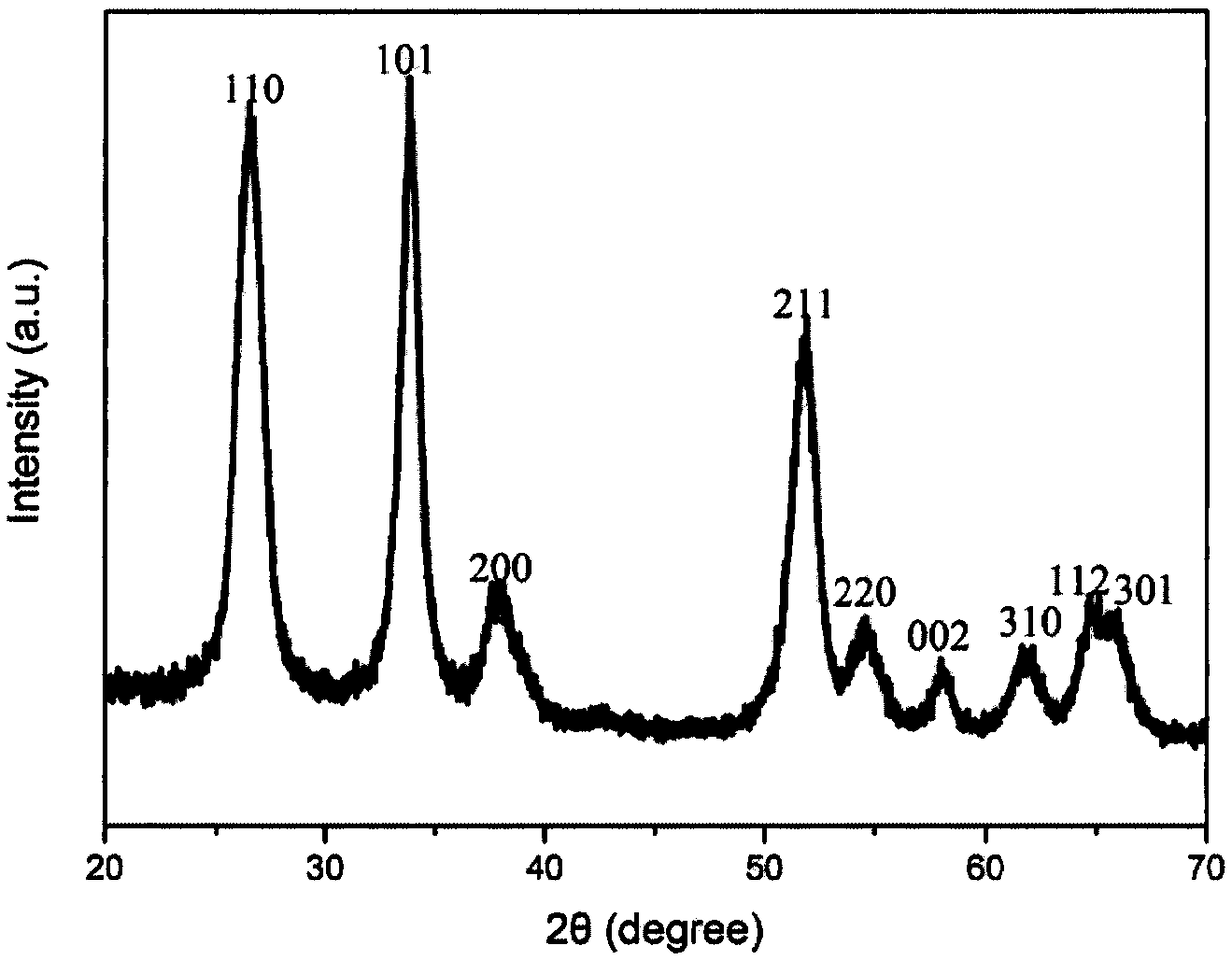

[0041] Embodiment 1, water-soluble SnO 2 Preparation of Inorganic Semiconductor Nanomaterials

[0042] Weigh 350mg of SnCl 4 ·5H2 O was dissolved in 6 mL of a mixed solvent of water and ethanol, the volume ratio of the mixed solvent of water and ethanol was 1:3, and stirred at room temperature until a clear solution was formed, and then 6 mL of 9% tetramethanone was added Ammonium hydroxide aqueous solution will produce white flocs in the solution instantly, stir vigorously until a clear and transparent solution is formed, and then transfer the clear and transparent solution to a polytetrafluoroethylene-lined autoclave, at 195 ° C Under the conditions of hydrothermal reaction for 12h. After natural cooling to room temperature, add 35mL of acetone to the clear solution to precipitate the product, remove the supernatant, disperse the precipitate in 10mL of ultrapure water to obtain a clear and transparent solution again, and then use 35mL of acetone to precipitate the product ...

Embodiment 2

[0045] Embodiment 2, described SnO 2 Preparation of Dispersion System of Inorganic Semiconductor Nanomaterials in Water Phase and Trifluoroethanol Phase

[0046] Weigh 100mg of the product obtained in Example 1, measure into 2mL of ultrapure water, and shake slightly to obtain 50mg / mL of aqueous SnO 2 Dispersion system; Weigh 20mg of the product obtained in Example 1, measure into 2mL of trifluoroethanol, ultrasonic 1h and stir for 12h to obtain 10mg / mL of trifluoroethanol phase SnO 2 decentralized system.

Embodiment 3

[0047] Embodiment 3, described SnO 2 Preparation of thin films of inorganic semiconductor nanomaterials

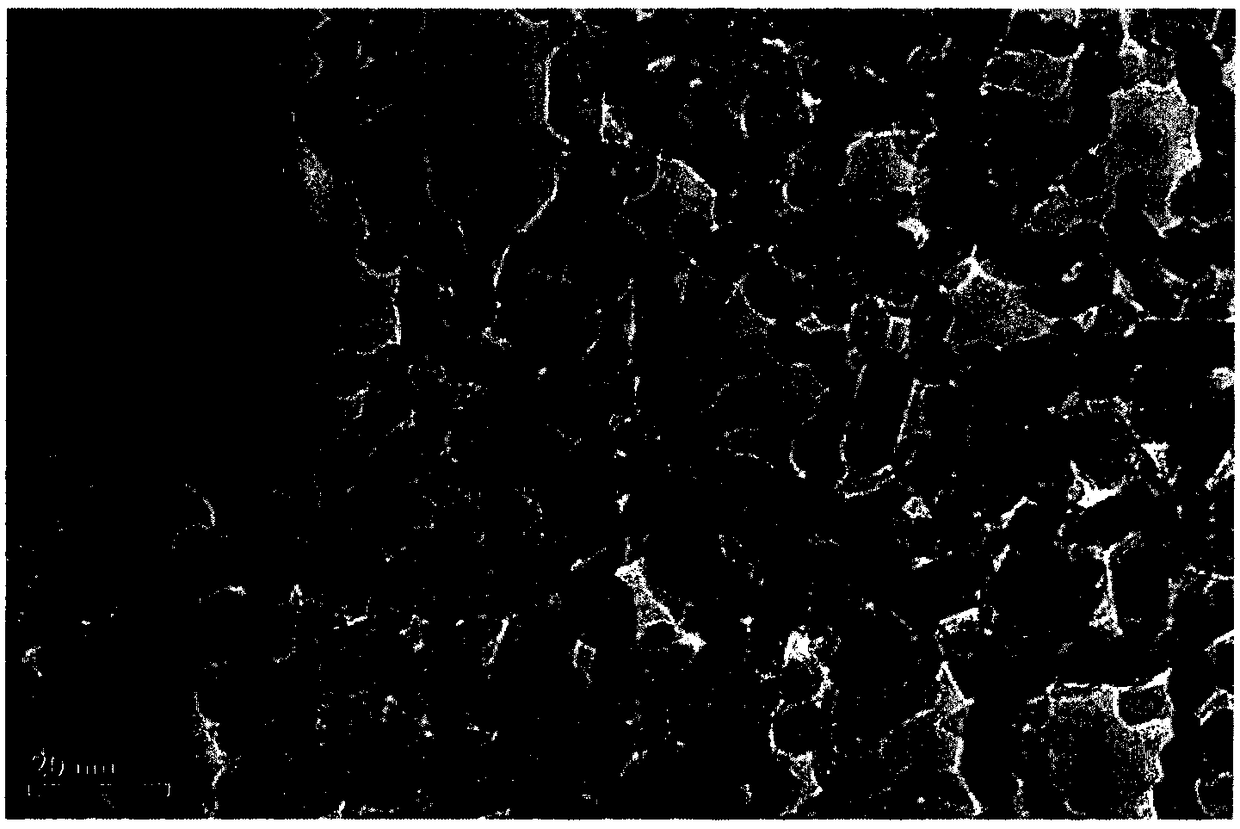

[0048] Prepare the aqueous phase SnO of the present invention of 30mg / mL by the method for embodiment 2 2 Dispersion system, SnO was prepared by spin coating on ITO substrate 2 Thin film; the trifluoroethanol phase SnO of the present invention prepared 10mg / mL by the method of embodiment 2 2 Dispersion system, SnO was prepared by spin-coating method on perovskite film 2 film. With the SnO prepared on ITO in embodiment 3 2 Surface morphology of thin films and SnO prepared by spin-coating method on perovskite thin films 2 Scanning electron microscopy (SEM) experiments were performed on the surface morphology of the films, and the results were as follows: Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com