Method for preparing supported ferrocyanide bacterial cellulose membrane for adsorbing Cs+

A technology of bacterial cellulose membrane and ferrocyanide, which is applied in chemical instruments and methods, adsorbed water/sewage treatment, radioactive pollutants, etc., can solve the problem of the preparation method and application of bacterial cellulose membrane-loaded ferrocyanide. related reports and other issues, to achieve the effect of easy utilization and separation, mild conditions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

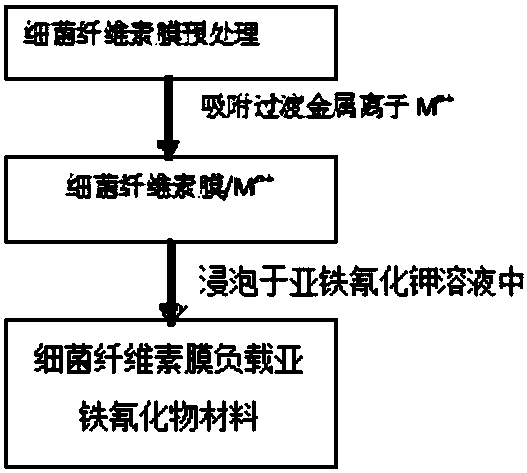

Method used

Image

Examples

Embodiment 1

[0023] Cut the bacterial cellulose membrane (thickness is about 1mm) into a circle with a diameter of about 3cm, soak it in a sodium hydroxide solution with a mass concentration of 1% at 60°C for 12h, and then wash the activated membrane with deionized water Bacterial cellulose membrane. Take the above bacterial cellulose membrane, respectively, with FeCl 3 Solution (0.5mol / L, 100mL) and potassium ferrocyanide solution (0.5mol / L, 100mL) were soaked for two hours, shaken with a shaker at a vibration rate of 100r / min, and washed twice with deionized water. The bacterial cellulose membrane-loaded ferrocyanide composite material is obtained.

Embodiment 2

[0025] Cut the bacterial cellulose membrane (thickness is about 1mm) into a circle with a diameter of about 3cm, soak it in a sodium hydroxide solution with a mass concentration of 1% at 60°C for 12h, and then wash the activated membrane with deionized water Bacterial cellulose membrane. Take the above-mentioned bacterial cellulose membrane, followed by CuSO 4 Solution (0.5mol / L, 100mL) and potassium ferrocyanide solution (0.5mol / L, 100mL) were soaked for two hours, shaken with a shaker at a vibration rate of 100r / min, and washed twice with deionized water. The bacterial cellulose membrane-supported copper ferrocyanide composite material was obtained.

Embodiment 3

[0027] Cut the bacterial cellulose membrane (thickness is about 1mm) into a circle with a diameter of about 3cm, soak it in a sodium hydroxide solution with a mass concentration of 1% at 60°C for 12h, and then wash the activated membrane with deionized water Bacterial cellulose membrane. Take the bacterial cellulose membrane above, and then use CoCl 2 Solution (0.5mol / L, 100mL) and potassium ferrocyanide solution (0.5mol / L, 100mL) were soaked for two hours, shaken with a shaker at a vibration rate of 100r / min, and washed twice with deionized water. The bacterial cellulose membrane-supported cobalt ferrocyanide composite material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Equilibrium adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com