Manufacturing method of ceramic thermal insulation wall material

A technology for thermal insulation walls and manufacturing methods, which is applied in the field of building materials, can solve problems such as low recycling rate, and achieve the effects of reduced energy consumption, uniform distribution, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

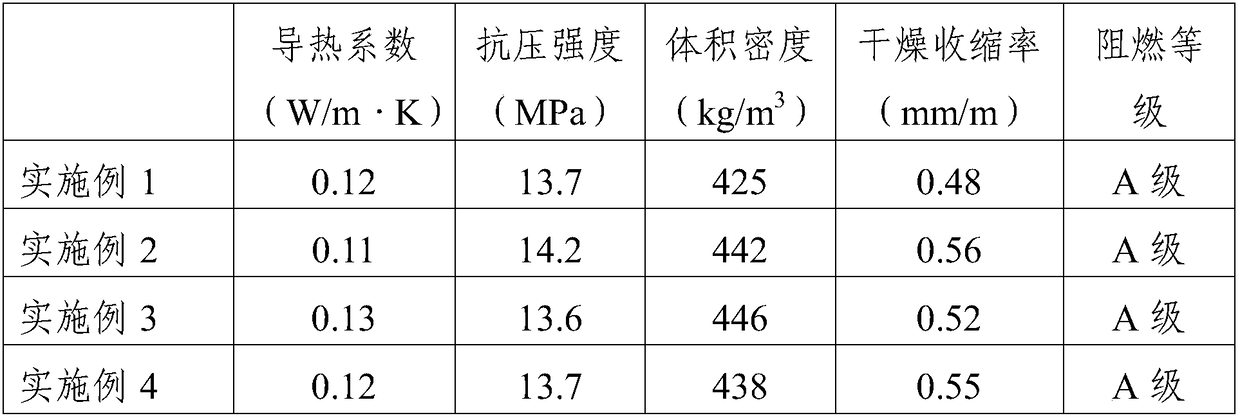

Examples

Embodiment 1

[0022] A method for making a ceramic thermal insulation wall material, comprising the following steps:

[0023] (1) Mix and grind ceramic polishing slag, bentonite, glass fiber, limestone and expanded perlite into powder and then dry it. The drying temperature is 110°C. The specific surface area of the dried mixture is greater than 500m 2 The fly ash, water, sodium terephthalate and sodium carboxymethyl cellulose of / kg, after stirring evenly, are placed in the mould, press molding at 8MPa, obtain blank;

[0024] (2) Cover one layer of plastic film on the surface of the blank, put the blank into an ultrasonic generator for ultrasonic treatment, the time of ultrasonic treatment is 30min, and the frequency of ultrasonic is 80KHz, remove the plastic film after ultrasonic treatment, and put Put the billet in a drying oven and dry to constant weight, the drying temperature is 100°C, and the weight of the dried billet does not change within 20 minutes, which is the constant weight...

Embodiment 2

[0027] A method for making a ceramic thermal insulation wall material, comprising the following steps:

[0028] (1) Mix and grind ceramic polishing slag, bentonite, glass fiber, limestone and expanded perlite into powder and then dry it. The drying temperature is 100°C. The specific surface area of the dried mixture is greater than 500m 2 Fly ash, water, sodium terephthalate and sodium carboxymethyl cellulose of / kg, after stirring evenly, be placed in the mould, press molding at 5MPa, obtain blank;

[0029] (2) Cover one layer of plastic film on the surface of the blank, put the blank into an ultrasonic generator for ultrasonic treatment, the time of ultrasonic treatment is 20min, and the frequency of ultrasonic is 50KHz, remove the plastic film after ultrasonic treatment, and put Put the billet in a drying oven and dry to constant weight, the drying temperature is 100°C, and the weight of the dried billet does not change within 20 minutes, which is the constant weight;

...

Embodiment 3

[0032] A method for making a ceramic thermal insulation wall material, comprising the following steps:

[0033] (1) Mix and grind ceramic polishing slag, bentonite, glass fiber, limestone and expanded perlite into powder and then dry it at a drying temperature of 120°C. The specific surface area of the dried mixture is greater than 500m 2 Fly ash, water, sodium terephthalate and sodium carboxymethyl cellulose of / kg, after stirring, be placed in the mould, press molding at 10MPa, obtain blank;

[0034] (2) Coat one layer of plastic film on the surface of the blank, put the blank into an ultrasonic generator for ultrasonic treatment, the time of ultrasonic treatment is 40min, and the frequency of ultrasonic is 100KHz, remove the plastic film after ultrasonic treatment, and place Put the billet in a drying oven and dry to constant weight, the drying temperature is 100°C, and the weight of the dried billet does not change within 20 minutes, which is the constant weight;

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com