Shape-controllable Scanning Tunneling Microscope Tip Preparation System

A scanning tunneling and preparation system technology, applied in the field of shape-controllable scanning tunneling microscope needle tip preparation system, can solve the problems of uncontrollable needle tip shape and blunt needle tip during corrosion process, achieve friendly software interface, convenient operation, and avoid corrosion The effect of too fast a process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with drawings and embodiments.

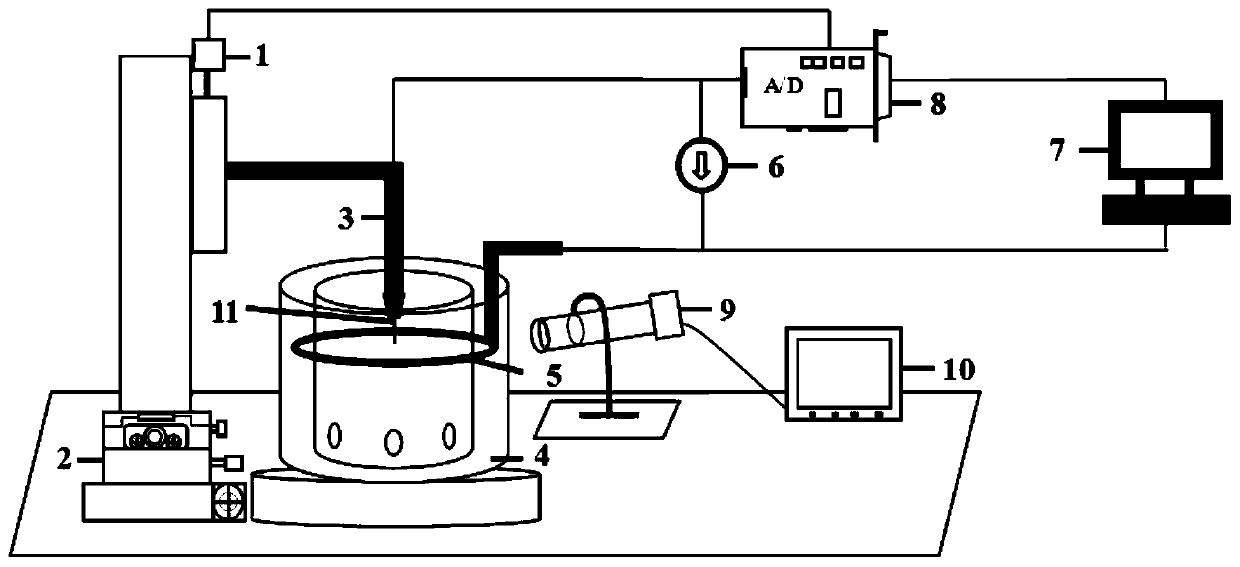

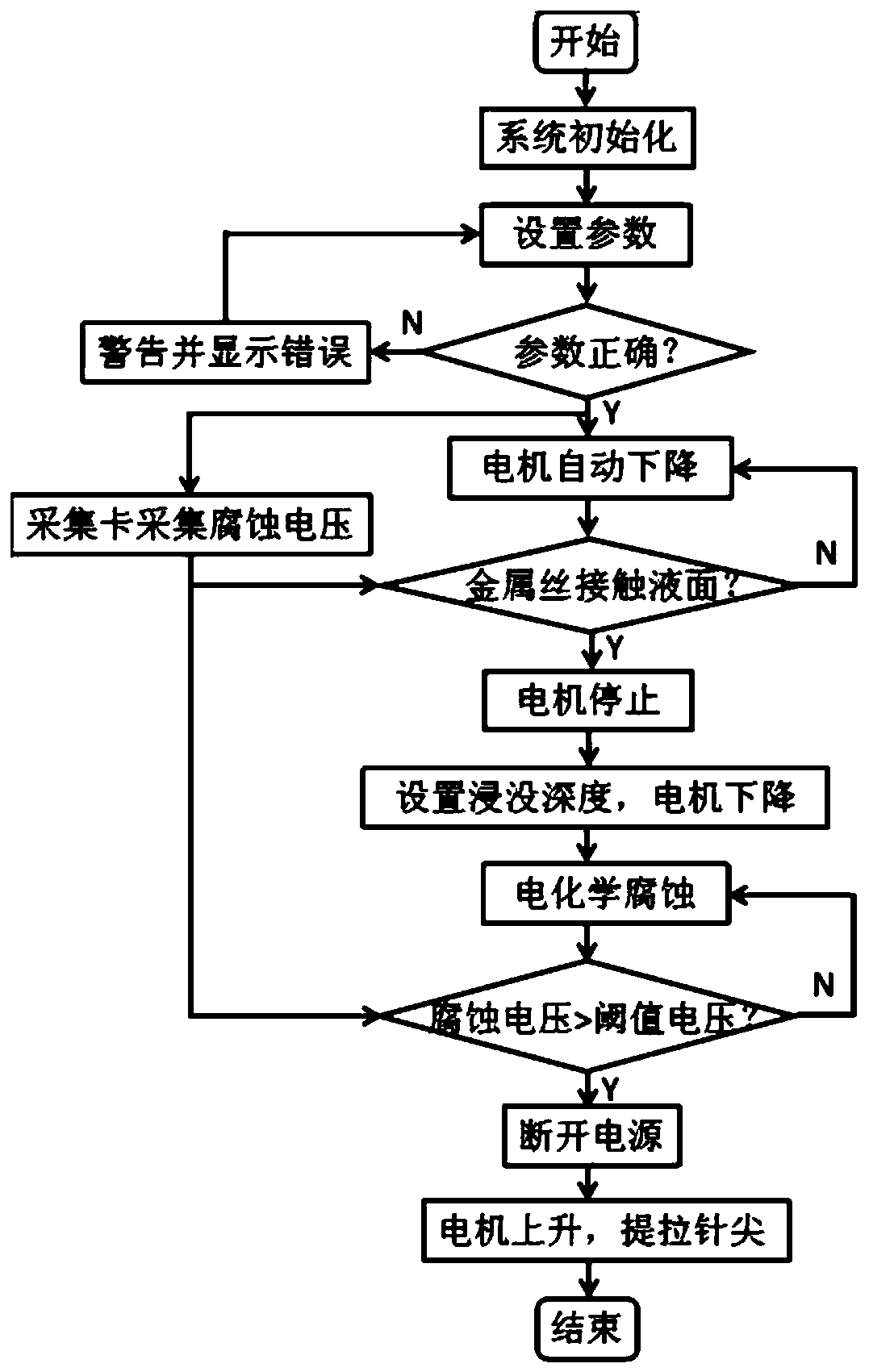

[0036] see figure 1 , the embodiment of the present invention is provided with a stepper motor 1, a three-dimensional translation stage 2, a probe clamping device 3, an annular structure electrolytic cell 4, a stainless steel ring 5, a programmable DC power supply 6, a computer 7, a data acquisition control card 8, and a CCD Camera 9 and display screen 10 . The stepper motor 1 is supported by a column, installed on the top of the three-dimensional translation platform 2, and connected with the probe clamping device 3, and is used for the positioning of the wire. The entire probe positioning mechanism is placed on the shock-absorbing platform; the ring-shaped electrolytic cell Corrosion solution is housed in 4, its cathode is a stainless steel ring 5, and its anode is a metal wire 11 to be corroded. , control its on, off and current output modes, and simultaneously con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com