Production technology for co-producing potassium sulfate and tripolycyanamide and production equipment thereof

A technology for melamine and a production process, which is applied to the production process of potassium sulfate co-producing melamine and the field of production equipment, can solve the problems of high energy consumption, high cost, load reduction of potassium sulfate devices, etc., and achieves low energy consumption, convenient processing, The effect of reducing pollution levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

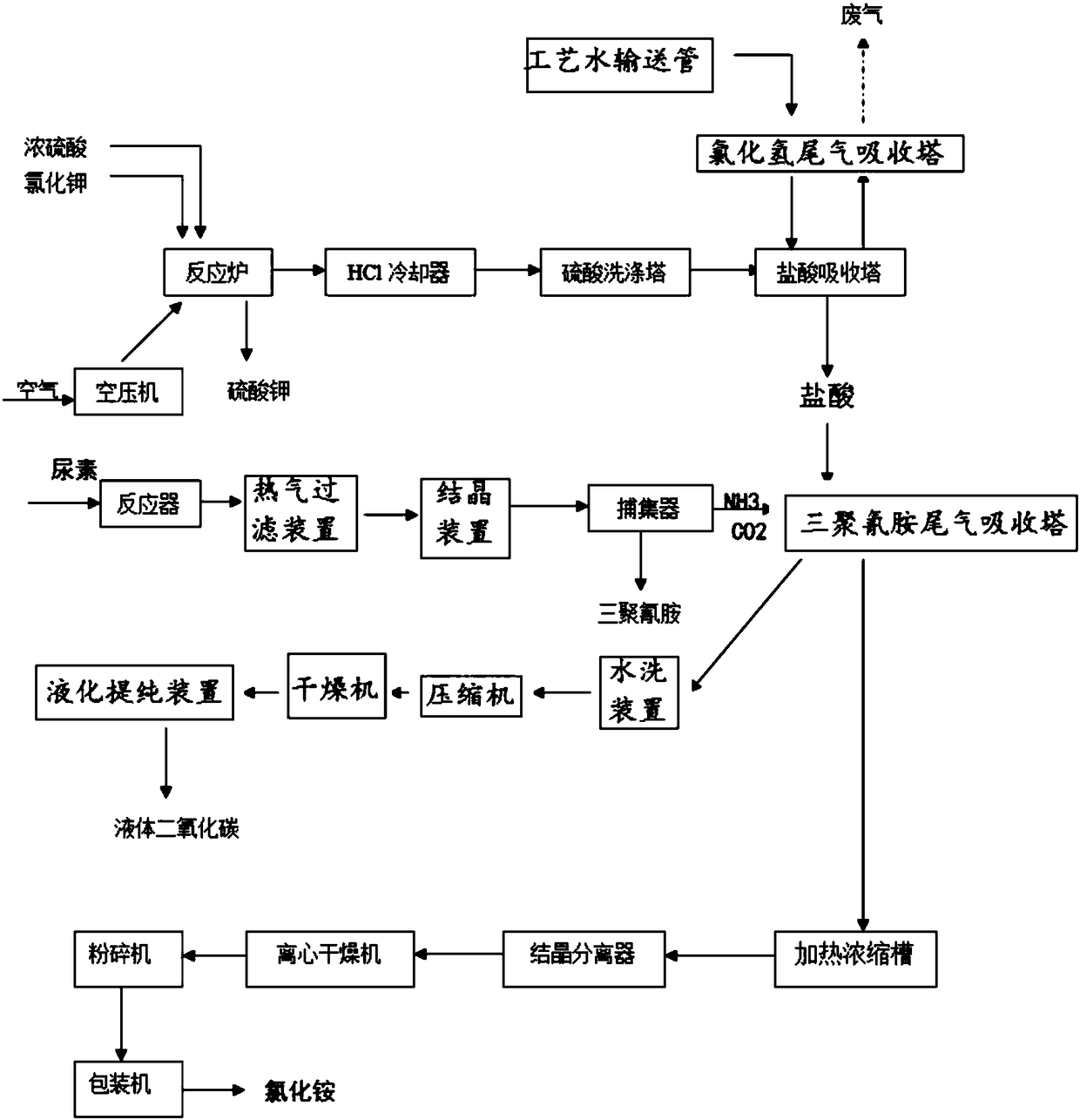

[0021] 1) the concentrated sulfuric acid, potassium chloride are input in the reaction furnace and react;

[0022] 2) the HCL produced in step 1) is delivered to the HCL condenser, then passed into the sulfuric acid washing tower for washing, and the resulting product is finally passed into the hydrochloric acid absorption tower to obtain hydrochloric acid;

[0023] 3) Pass urea into the reactor, then filter the obtained product with hot gas, recrystallize, and finally pass the obtained crystals into the trap, and the obtained products include melamine, ammonia and carbon dioxide;

[0024] 4) Pass the ammonia and carbon dioxide obtained in step 3) into the melamine tail gas absorption tower, and simultaneously pass the hydrochloric acid prepared in step 2) into the melamine tail gas absorption tower;

[0025] 5) After the melamine tail gas absorption tower washes and absorbs the synthetic ammonia in the tail gas of melamine production, the ammonium chloride liquid produced ent...

Embodiment 2

[0028] After being washed and absorbed by the melamine tail gas absorption tower, the carbon dioxide gas that removes the synthetic ammonia is washed, compressed, pretreated, dried, liquefied, and purified to obtain a liquid food-grade carbon dioxide product.

[0029] After washing and absorbing the melamine tail gas absorption tower to remove the carbon dioxide gas from synthetic ammonia, it can be washed, compressed, pretreated, dried, liquefied, and purified to obtain liquid food-grade carbon dioxide products. Such tail gas treatment reduces the degree of pollution to the environment. The effect of environmental protection, and low energy consumption, reduces production costs and improves profit margins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com