Alginic acid seawater desalination pretreatment technology and preparation of alginic acid compound salt fiber

A kind of alginic acid and pretreatment technology, applied in seawater treatment, ion exchange water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., to reduce the cost of seawater desalination technology, high hygroscopicity, and promote the effect of wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

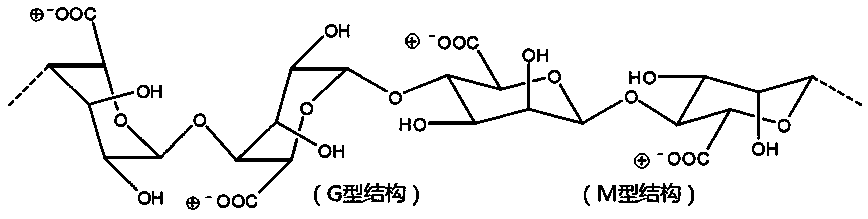

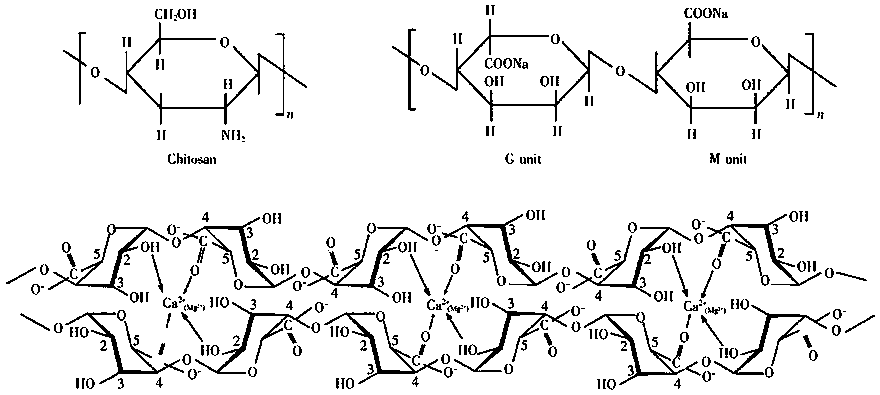

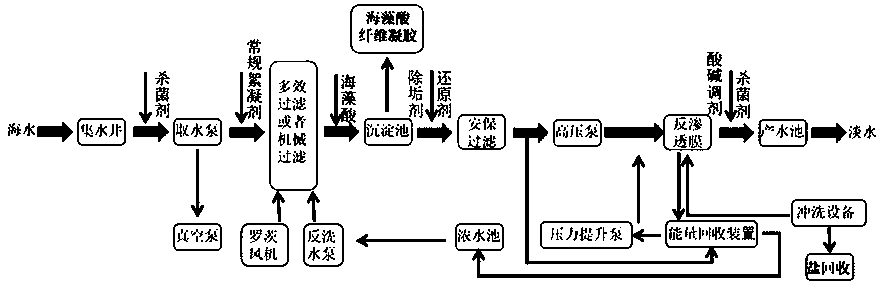

[0018] Dissolve alginic acid with a G-type content of 80% in the seawater pretreated by multi-effect filtration or mechanical filtration at a mass ratio of 100:3. Alginic acid interacts with sodium ions (Na + ), potassium ions (K + ), magnesium ions (Mg 2+ ), calcium ions (Ca 2+ ) ions combined to precipitate an alginate compound salt gel with a mass ratio of 7.1%, and the salt content of seawater dropped to 23500ppm. The extracted gel was prepared into fibers by gel spinning method, and dried at 60° C. to obtain alginic acid composite salt fibers. The moisture absorption rate of the fiber reaches 98%, the antibacterial rate against Escherichia coli reaches 28.5%, and the antibacterial rate against Staphylococcus aureus reaches 43.8%.

Embodiment 2

[0020] Dissolve alginic acid with a G-type content of 75% in the seawater pretreated by multi-effect filtration or mechanical filtration at a mass ratio of 100:4. Alginic acid interacts with sodium ions (Na + ), potassium ions (K + ), magnesium ions (Mg 2+ ), calcium ions (Ca 2+ ) ions were combined to precipitate an alginate compound salt gel with a mass ratio of 7.0%, and the salt content of seawater dropped to 24800ppm. The extracted gel was prepared into fibers by gel spinning method, and dried at 60° C. to obtain alginic acid composite salt fibers. The moisture absorption rate of the fiber reaches 97.5%, the antibacterial rate against Escherichia coli reaches 29.9%, and the antibacterial rate against Staphylococcus aureus reaches 44.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com