Preparation method of ferric oxide/carbon/carbon nanotube lithium-ion battery negative electrode material

A technology of ferric oxide and lithium-ion batteries, which is applied in the direction of carbon nanotubes, battery electrodes, secondary batteries, etc., can solve the problems of electrochemical performance, unsatisfactory cycle stability, poor conductivity, etc., and achieve improved cycle Stability, easy control of particle size, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of activated carbon nanotubes

[0026] (1) Weigh 1g of carbon nanotubes (CNT) (purified, particle size 30-50nm) and 4g of KOH (ratio: 1:4) with an electronic scale and put them into an agate mortar to grind and mix them evenly, then Then pour it into a 150ml beaker and add 100ml of distilled water to mix, and stir for 30min with a magnetic stirrer;

[0027] (2) drying the product obtained in step (1) in a drying oven at 100° C. in air for 24 hours, and evaporating all the water in the mixture to obtain a dried mixture;

[0028](3) Put the product obtained in step (2) into a horizontal tube furnace with a ceramic boat and feed nitrogen gas at 240ml / min, heat up to 850°C at a rate of 5°C / min and keep it warm for 1 hour, then cool to room temperature and take it out. Carbon nanotubes have been activated by KOH, and KOH is embedded in the tube wall of carbon nanotubes;

[0029] (4) Due to the existence of KOH, (3) the resulting carbon nanotubes are alkaline...

Embodiment 2

[0042] Others are the same as Example 1, and the difference is that the second step prepares Fe 2 o 3 In step (4) of the / CNT material, place it in a polytetrafluoroethylene reactor lining, and react in a constant temperature box at 210°C for 9 hours.

Embodiment 3

[0044] Others are the same as Example 1, and the difference is that the second step prepares Fe 2 o 3 In step (4) of the / CNT material, place it in a polytetrafluoroethylene reactor lining, and react for 9 hours at 230° C. in a thermostat.

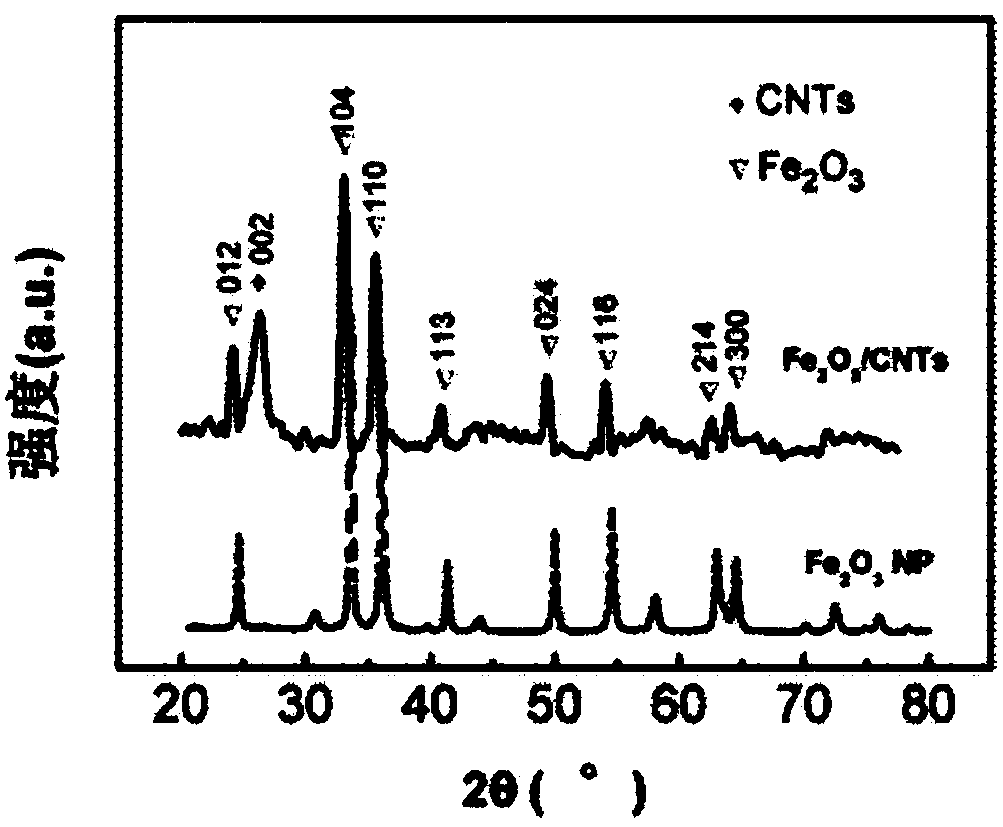

[0045] figure 1 It is the obtained ferric oxide / carbon / carbon nanotube (Fe 2 o 3 / CNT) low-magnification SEM images. It can be seen from the XRD pattern that Fe was successfully synthesized by the hydrothermal method 2 o 3 Composite materials with carbon nanotubes

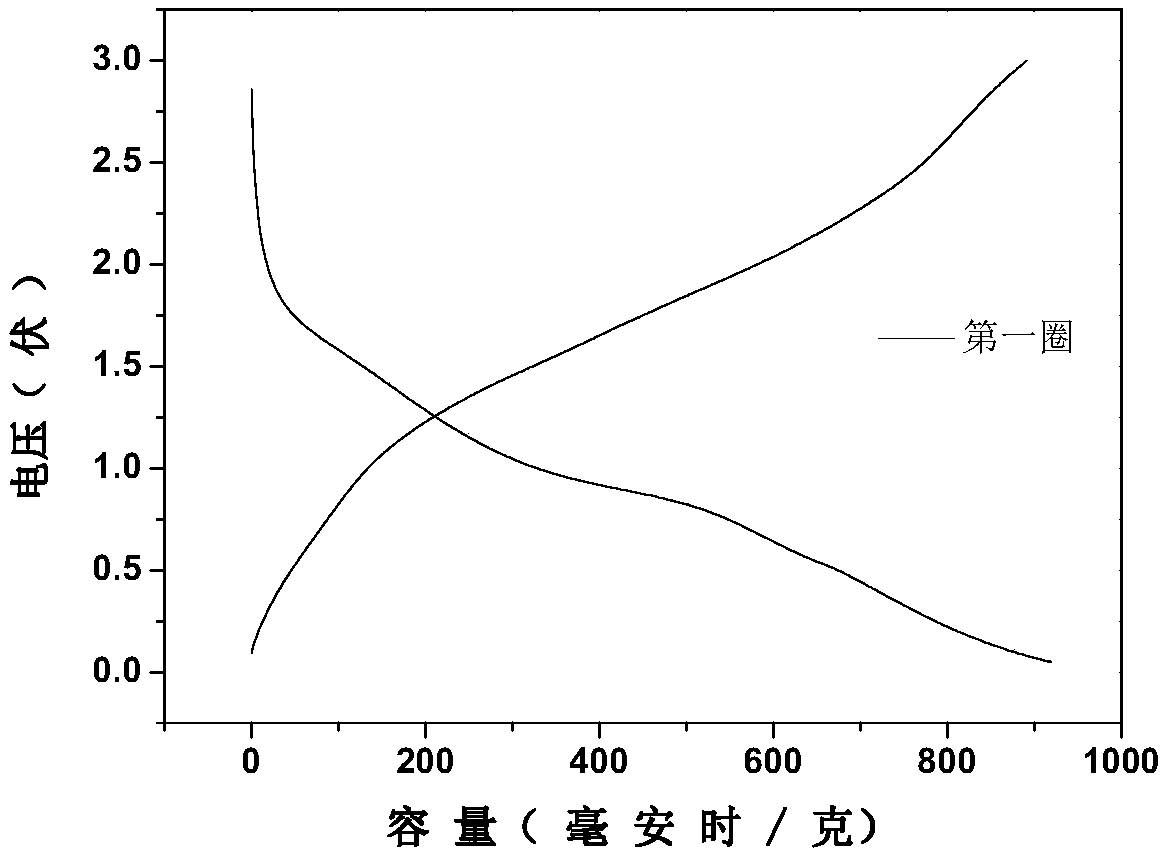

[0046] figure 2 It is the obtained ferric oxide / carbon / carbon nanotube (Fe 2 o 3 / C / CNT) XRD pattern. It can be seen from the SEM image that the carbon-coated iron oxide balls are evenly attached to the surface of the carbon nanotubes, which shows that we have successfully compounded the core-shaped iron oxide balls on the carbon nanotubes. On the surface of nanotubes, this composite material has good electrical conductivity, Coulombic efficiency and high capacity. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com