CuInS2 quantum dot/rGO composite photocatalytic material and application thereof

A composite photocatalysis and quantum dot technology, which can be used in luminescent materials, physical/chemical process catalysts, nano-optics, etc., and can solve the problems of photocatalytic performance inhibition and quantum dot stability reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

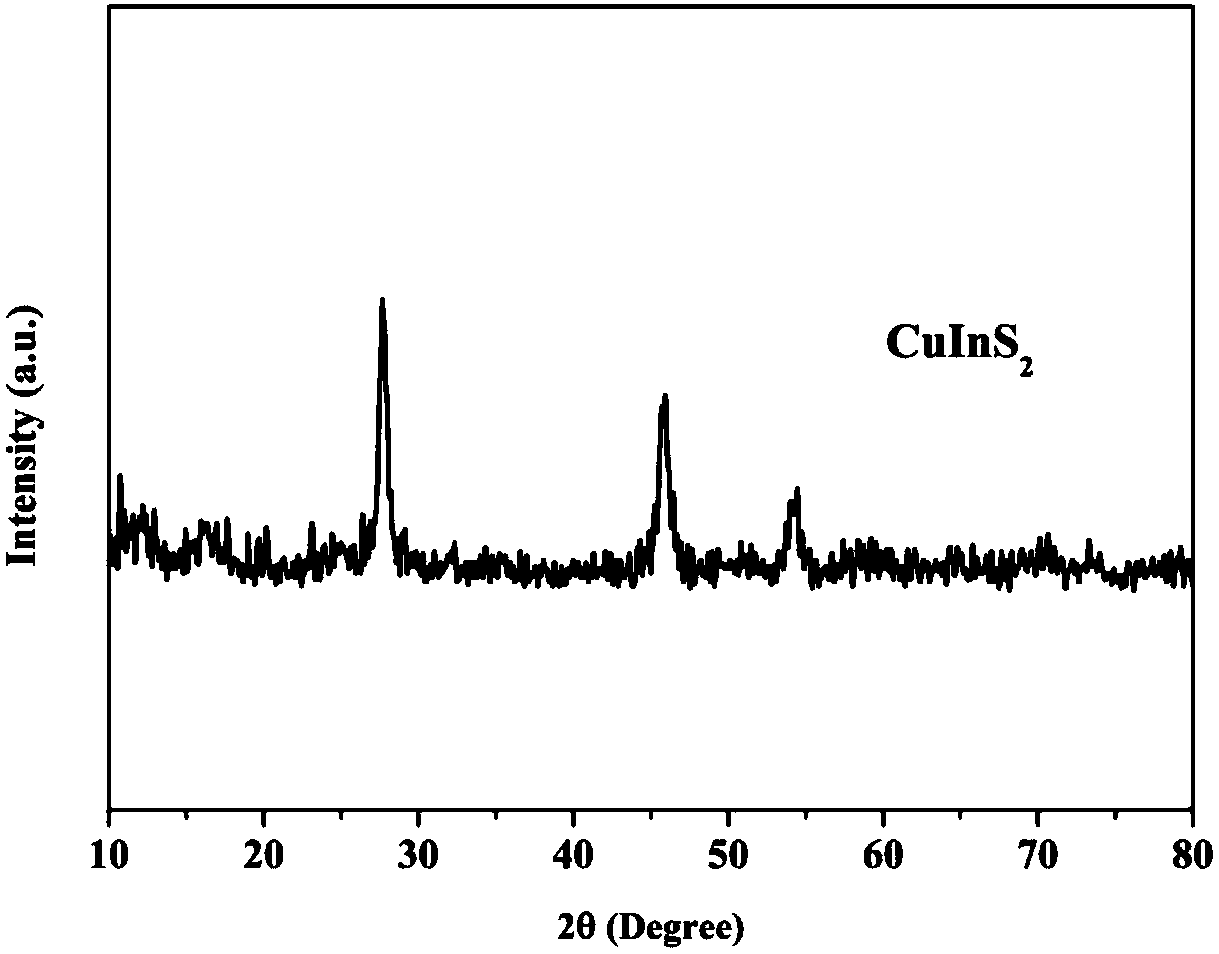

[0024] (1)CuInS 2 Preparation:

[0025] Weigh 0.438g In(Ac) 3 (Indium acetate), 0.285g CuI (cuprous iodide) and 5mL dodecanethiol (DDT) are mixed in a three-necked flask, heated to 210℃ in an oil bath, and heated continuously under an argon protective atmosphere. After the reactant solution turns black, immediately immerse the three-necked flask in cold water at 20°C for 5 min. The obtained sample is washed with toluene / methanol three times, and the solid obtained after being lyophilized in a freeze dryer for 24 hours is CuInS. 2 .

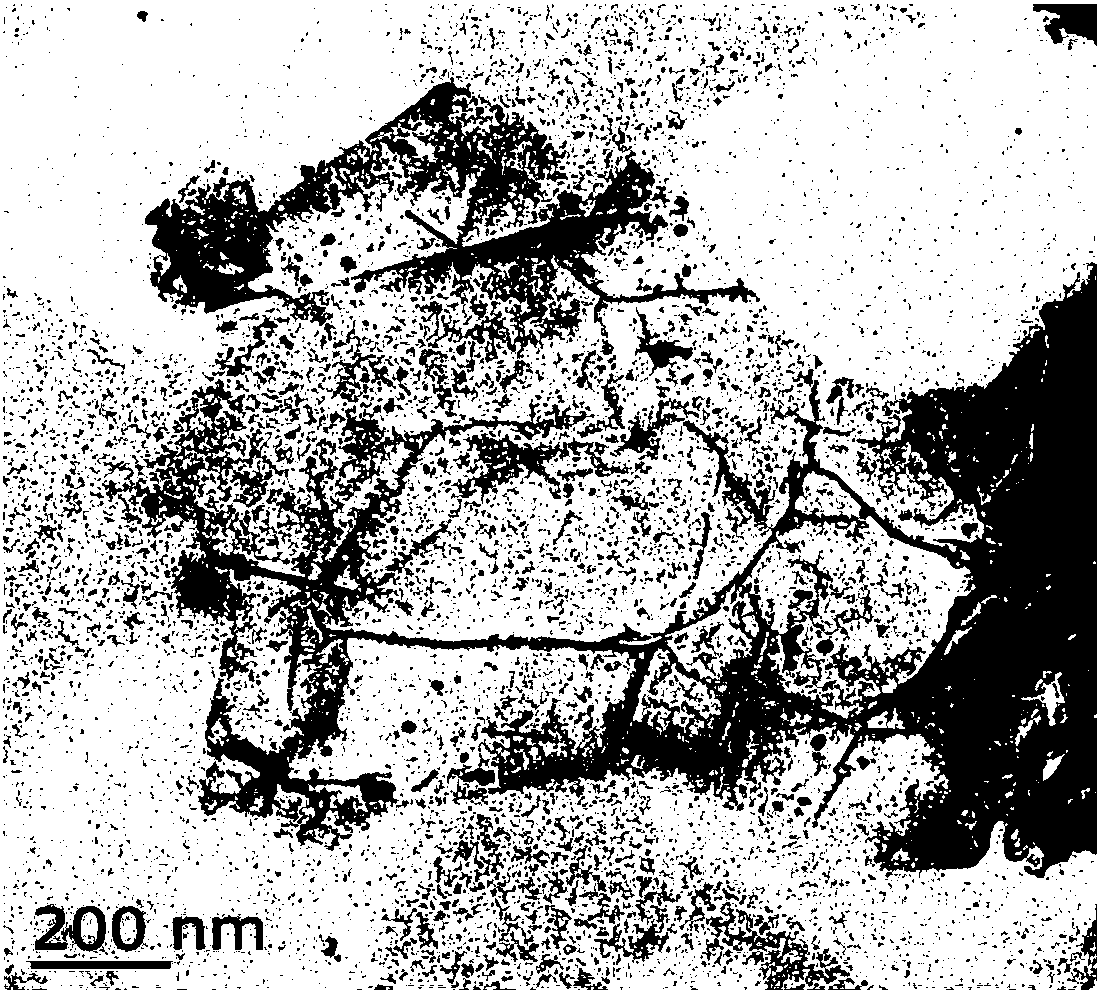

[0026] (2)CuInS 2 / rGO composite photocatalyst preparation:

[0027] Put 0.8g CuInS prepared in step (1) 2 Dissolve in methanol, then add 0.4g GO powder, then pour the system into an autoclave and heat it in an oven at 200°C, continue the reaction for 1 hour, take it out to cool naturally, centrifuge the solution, and wash it with deionized water and methanol for 3 times. Dry in a drying oven at 70℃ to obtain CuInS 2 / rGO composite photocatalyst.

[0028...

Embodiment 2

[0030] (1)CuInS 2 Preparation:

[0031] Weigh 0.438g In(Ac) 3 (Indium acetate), 0.285g CuI (cuprous iodide) and 7.5mL dodecanethiol (DDT) were mixed in a three-necked flask, put in an oil bath and heated to 210℃, and heated continuously under an argon atmosphere After the reactant solution turns black, immediately immerse the three-necked flask in cold water at 20°C and cool for 5 min. The obtained sample is washed with toluene / methanol 3 times, and the solid obtained after being lyophilized in a freeze dryer for 24 hours is CuInS 2 .

[0032] (2)CuInS 2 / rGO composite photocatalyst preparation:

[0033] Put 0.8g CuInS prepared in step (1) 2 Dissolve in methanol, then add 0.4g GO powder, then pour the system into an autoclave and heat it in an oven at 200°C, continue the reaction for 1 hour, take it out to cool naturally, centrifuge the solution, and wash it with deionized water and methanol for 3 times. Dry in a drying oven at 70℃ to obtain CuInS 2 / rGO composite photocatalyst.

[...

Embodiment 3

[0036] (1)CuInS 2 Preparation:

[0037] Weigh 0.438g In(Ac) 3 (Indium acetate), 0.285g CuI (cuprous iodide) and 10mL dodecanethiol (DDT) were mixed in a three-necked flask, heated to 210℃ in an oil bath, and heated continuously under an argon protective atmosphere. After the reactant solution turns black, immediately immerse the three-necked flask in cold water at 20°C for 5 min. The obtained sample is washed with toluene / methanol three times, and the solid obtained after being lyophilized in a freeze dryer for 24 hours is CuInS. 2 .

[0038] (2)CuInS 2 / rGO composite photocatalyst preparation:

[0039] Put 0.8g CuInS prepared in step (1) 2 Dissolve in methanol, then add 0.4g GO powder, then pour the system into an autoclave and heat it in an oven at 200°C, continue the reaction for 1 hour, take it out to cool naturally, centrifuge the solution, and wash it with deionized water and methanol for 3 times. Dry in a drying oven at 70℃ to obtain CuInS 2 / rGO composite photocatalyst.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com