Device and method for preparing functional graphene

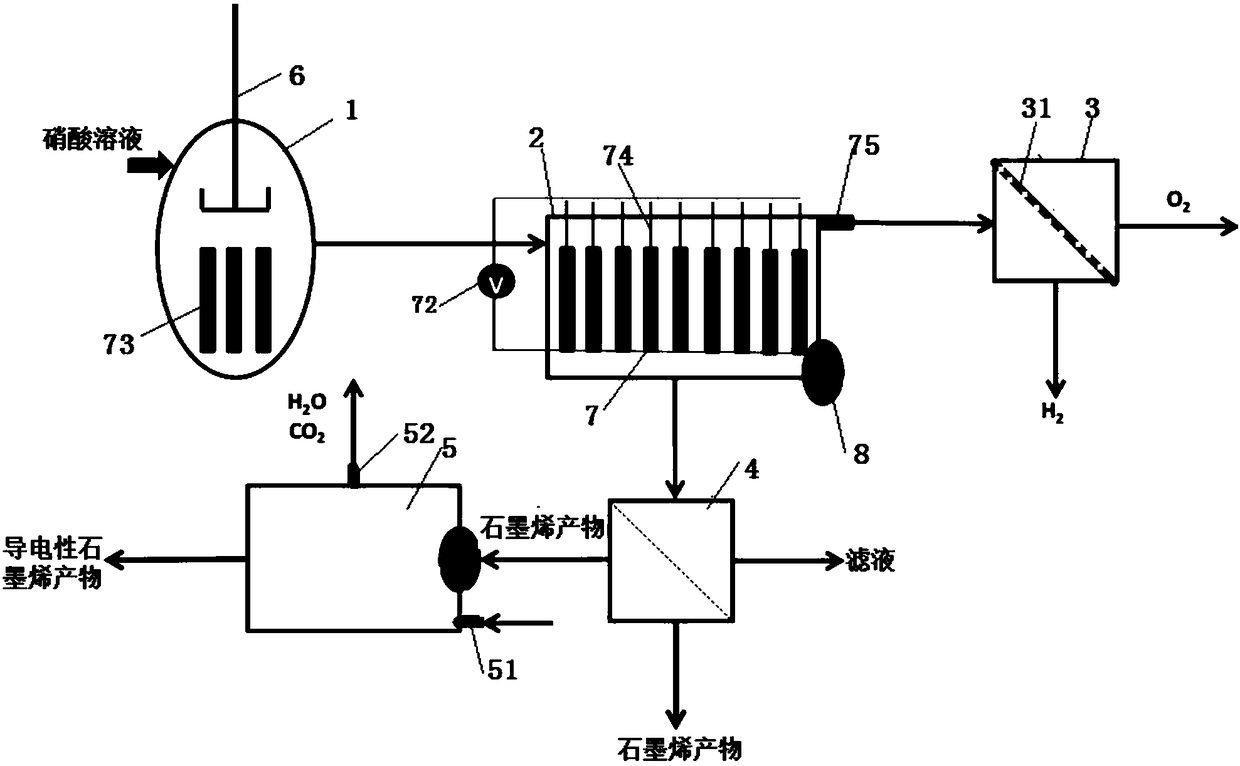

A graphene and fossil technology, applied in the field of devices for preparing functionalized graphene, can solve complex time-consuming and toxic wastewater problems, and achieve the effects of simplifying operation steps, saving time, and avoiding wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Utilize above-mentioned device to prepare the method for functionalized graphene, comprise the steps:

[0035] S1. Dissolve nitric acid in distilled water to form a nitric acid solution with a concentration of 1mol / L. Add the graphite column and the nitric acid solution into the acidification reactor. The ratio of the graphite column to the nitric acid solution (weight ratio) is 1:1, and stir the acidification reaction. 30min, the graphite column that makes acidification;

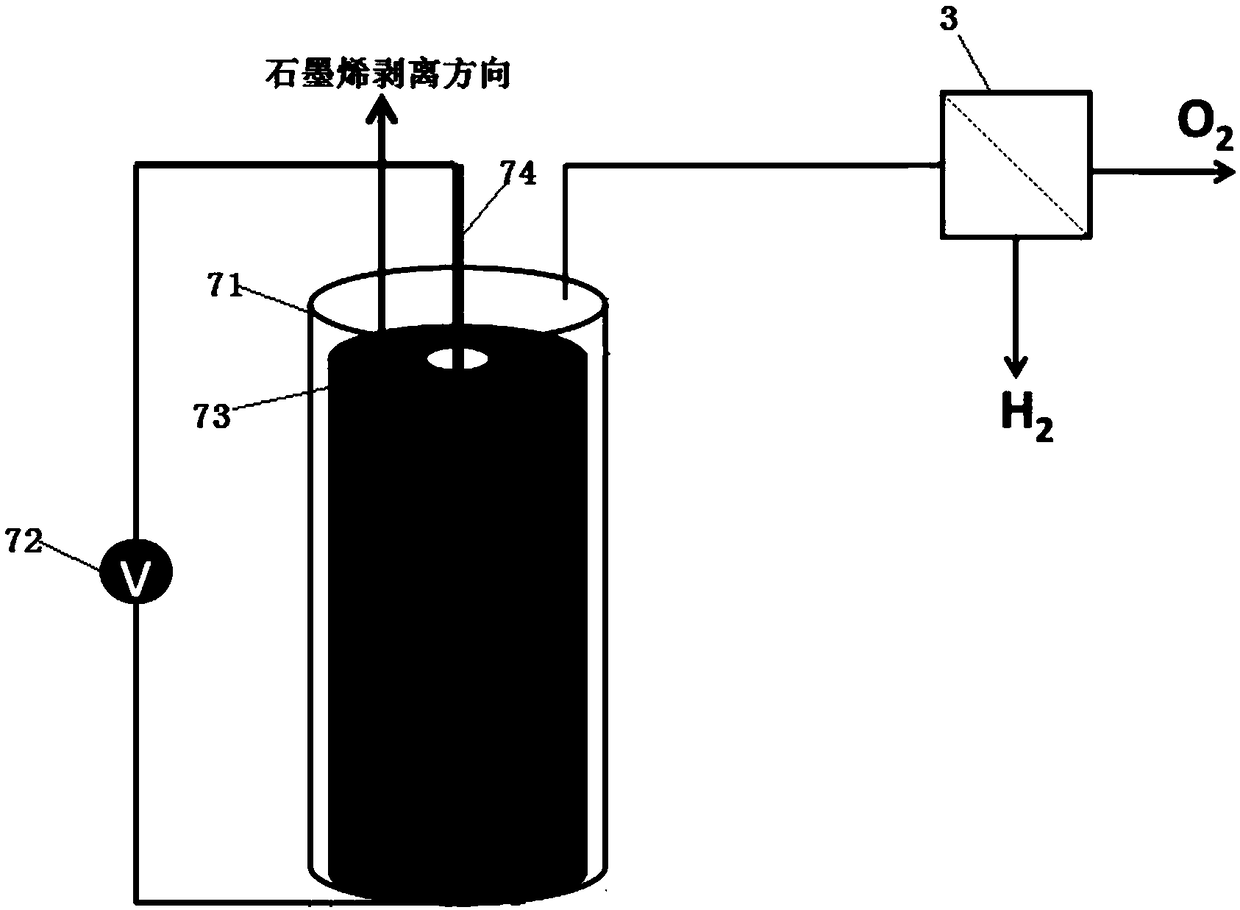

[0036] S2. Open a blind hole in the center of the acidified graphene, then place the graphite column in the electrolytic cell as the positive electrode, insert the platinum wire into the blind hole as the positive electrode, connect the bottom of the graphite column to the power supply, and connect the top of the platinum wire to the power supply. Select a mass percentage of 10 % of (NH 4 ) 2 HPO 4 Aqueous solution is used as the electrolyte, 200ml of electrolyte is added to the electrolytic cell,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com