Method for fast preparing small-particle-diameter anatase type nanometer titanium dioxide

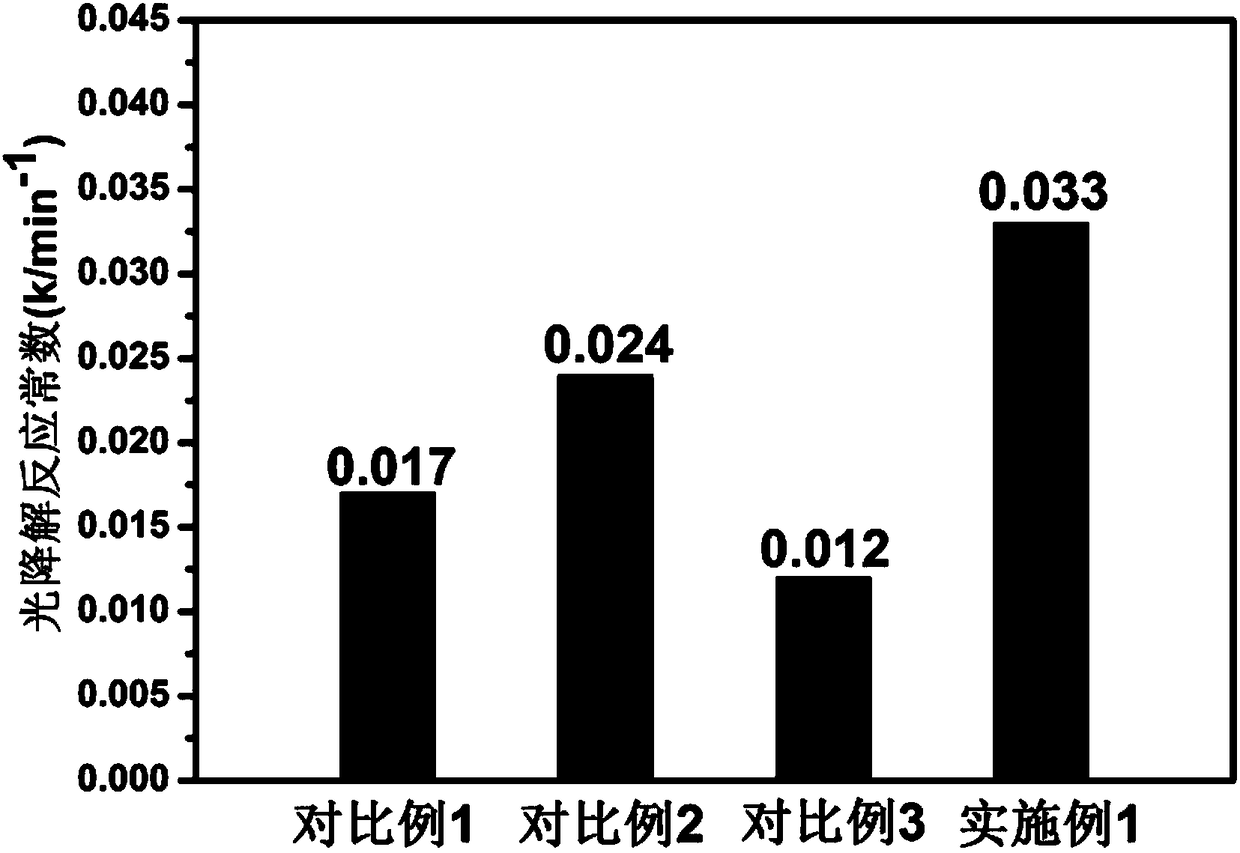

A nano-titanium dioxide and anatase-type technology, which is applied in the field of nano-materials, can solve the problems of cumbersome procedures, difficult product grain size to reach the nanometer level, and insufficient simplicity, so as to achieve good photocatalytic activity, good application prospects, and time-consuming short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for rapidly synthesizing anatase nano-titanium dioxide, the specific steps are as follows:

[0032] (1) Add 1.5mL of ammonia water (concentration 10mol / L) to a mixture of 40mL of deionized water and 10mL of ethylene glycol, and add 2mL of tetrabutyl titanate and 1mL of 1- Butyl-3-methylimidazolium tetrafluoroborate;

[0033] (2) Transfer the uniformly mixed above-mentioned solution to a microwave reactor, and heat it at 180° C. for 10 minutes by microwave hydrothermal method;

[0034] (3) After the reaction kettle is cooled to room temperature, take out the reaction solution, centrifuge and wash alternately with deionized water and ethanol. After washing several times, put the sample in an oven at 60°C for at least 12 hours, and then transfer it to a muffle furnace. The temperature was raised to 600°C at a rate of 1°C / min, kept for 4 hours for calcination, and finally cooled with the furnace to obtain a titanium dioxide sample.

[0035] Figure 4 c is a larg...

Embodiment 2

[0063] A method for rapidly synthesizing anatase nano-titanium dioxide, comprising the following steps:

[0064] (1) Add 1.5 mL of ammonia water (concentration 10 mol / L) to a mixed solution of 40 mL of deionized water and 10 mL of ethylene glycol, and add 2 mL of tetrabutyl titanate and 1 mL of 1- Butyl-3-methylimidazolium tetrafluoroborate;

[0065] (2) Transfer the uniformly mixed above-mentioned solution to a microwave reactor, and heat it at 150° C. for 15 minutes by microwave hydrothermal method;

[0066] (3) After the reaction kettle is cooled to room temperature, take out the reaction solution, centrifuge and wash alternately with deionized water and ethanol. After washing several times, put the sample in an oven at 60°C for at least 12 hours, and then transfer it to a muffle furnace. Raise the temperature to 650°C at a rate of 3°C / min, keep the temperature for 4h for calcination, and finally cool down with the furnace to obtain a titanium dioxide sample.

[0067] The...

Embodiment 3

[0069] A method for rapidly synthesizing anatase nano-titanium dioxide, comprising the following steps:

[0070] (1) Add 1.5 mL of ammonia water (concentration 15 mol / L) into a mixed solution of 40 mL of deionized water and 10 mL of ethylene glycol, and add 2 mL of tetrabutyl titanate and 1 mL of 1- Butyl-3-methylimidazolium tetrafluoroborate;

[0071] (2) Transfer the uniformly mixed above-mentioned solution to a microwave reactor, and heat it at 180° C. for 10 minutes by microwave hydrothermal method;

[0072] (3) After the reaction kettle is cooled to room temperature, take out the reaction solution, centrifuge and wash alternately with deionized water and ethanol. After washing several times, put the sample in an oven at 60°C for at least 12 hours, and then transfer it to a muffle furnace. Raise the temperature to 550°C at a rate of 1°C / min, keep the temperature for 6h for calcination, and finally cool down with the furnace to obtain a titanium dioxide sample.

[0073] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com