Method for stabilizing nitrosification based on ammonia-nitrogen adsorption material strengthened membrane bioreactor

A membrane bioreactor, bioreactor technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problem of no stable nitrosation method, etc., and achieve stable and efficient nitrosation and ammonia nitrogen. Efficacy of high treatment loads and reduced toxic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

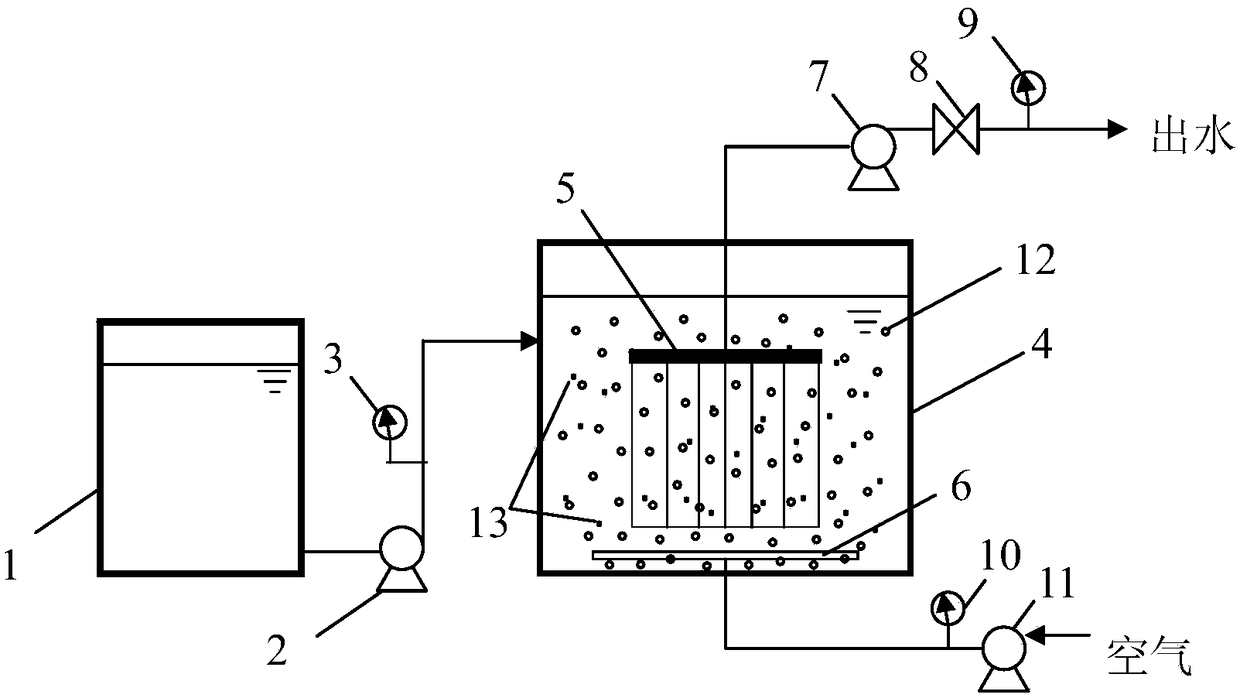

[0029] A method for stabilizing nitrification in a membrane bioreactor based on an ammonia nitrogen adsorption material, comprising the following steps:

[0030] (1) In the membrane bioreactor, add aerobic nitrification sludge with a sludge concentration of 3500mg / L, and add ammonia nitrogen (such as ammonium chloride) at a dissolved oxygen of 0.1-1.0mg / L and a temperature of 38°C , the concentration of ammonia nitrogen was 50mg / L, and the stuffy exposure was carried out. After 1 day of stuffy exposure, the removal rate of ammonia nitrogen was 97.4%, and the sludge cultivation was successful;

[0031] (2) After the sludge cultivation is completed, add artificial zeolite with a particle size of 100-200 mesh to the membrane bioreactor, and the dosage is 1%wt; then the ammonia nitrogen concentration is about 100mg / L, and the nitrite nitrogen concentration Wastewater with a concentration of 0.1mg / L, a concentration of nitrate nitrogen of 0.2mg / L, and a pH of 9.5 is passed into the...

Embodiment 2

[0033] A method for stabilizing nitrification in a membrane bioreactor based on an ammonia nitrogen adsorption material, comprising the following steps:

[0034] (1) In the membrane bioreactor, add aerobic activated sludge with a sludge concentration of 5500mg / L, add ammonia nitrogen at a dissolved oxygen of 2.0-3.0mg / L and a temperature of 28°C, and the concentration of ammonia nitrogen is 200mg / L , carried out stuffy exposure, after 2 days of stuffy exposure, the removal rate of ammonia nitrogen was 92.7%, and the sludge cultivation was successful;

[0035] (2) After the sludge cultivation is completed, add natural zeolite with a particle size of 80-100 mesh to the membrane bioreactor, and the dosage is 3%wt; then the ammonia nitrogen concentration is about 350mg / L, and the nitrite nitrogen concentration 0.8mg / L, nitrate nitrogen concentration 1.0mg / L, pH 7.9 waste water is passed into the membrane bioreactor, dissolved oxygen is controlled at 2.0-3.0mg / L, water temperature ...

Embodiment 3

[0037] A method for stabilizing nitrification in a membrane bioreactor based on an ammonia nitrogen adsorption material, comprising the following steps:

[0038] (1) In the membrane bioreactor, add aerobic activated sludge with a sludge concentration of 7000mg / L, add ammonia nitrogen at a dissolved oxygen of 4.0-5.0mg / L and a temperature of 24°C, and the ammonia nitrogen concentration is 200mg / L , carry out stuffy exposure, after 2 days of stuffy exposure, the removal rate of ammonia nitrogen is 90.7%, and the sludge cultivation is successful;

[0039] (2) After the sludge cultivation is completed, add artificial zeolite with a particle size of 200 to 400 mesh into the membrane bioreactor, and the dosage is 5% wt, and then the ammonia nitrogen concentration is about 600mg / L, and the nitrite nitrogen concentration is about 600mg / L. 0.0mg / L, nitrate nitrogen concentration 0.0mg / L, pH 8.2 waste water is passed into the membrane bioreactor, the dissolved oxygen is controlled at 4....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com