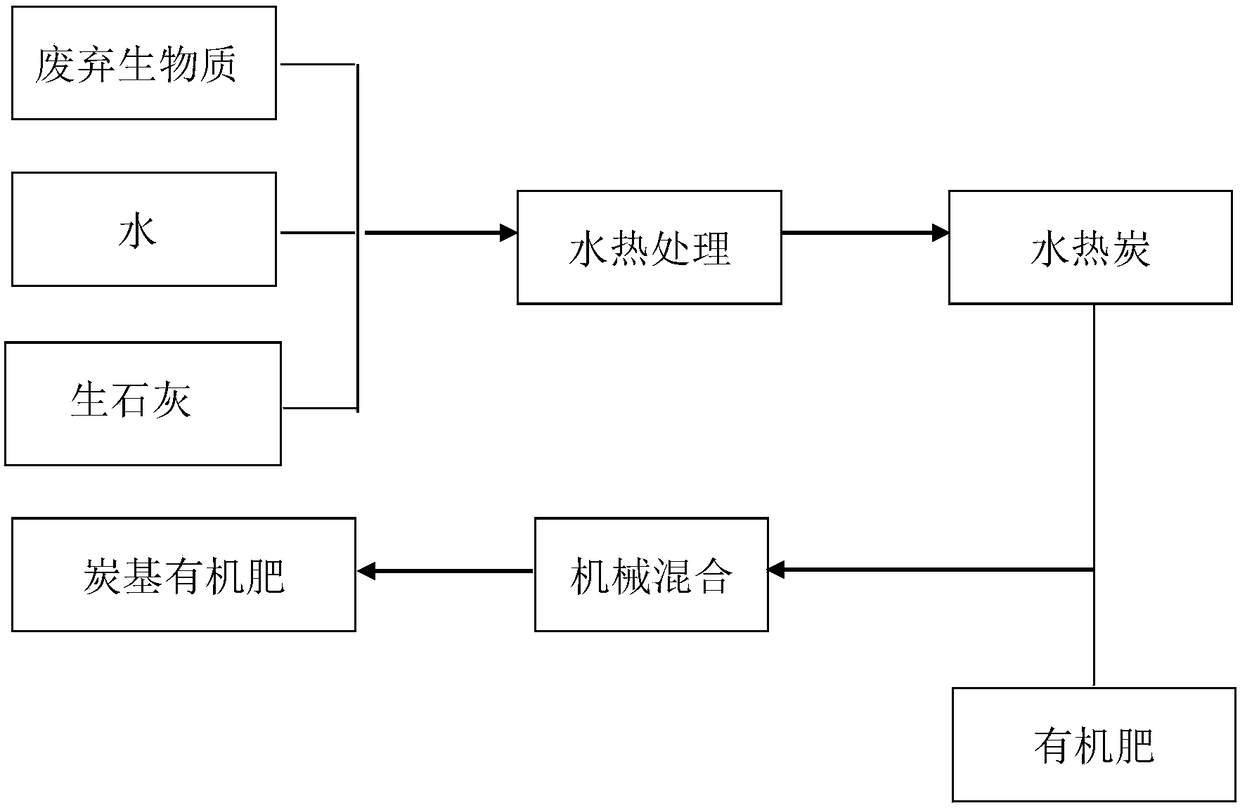

Method for preparing carbon-based organic fertilizer from waste biomass

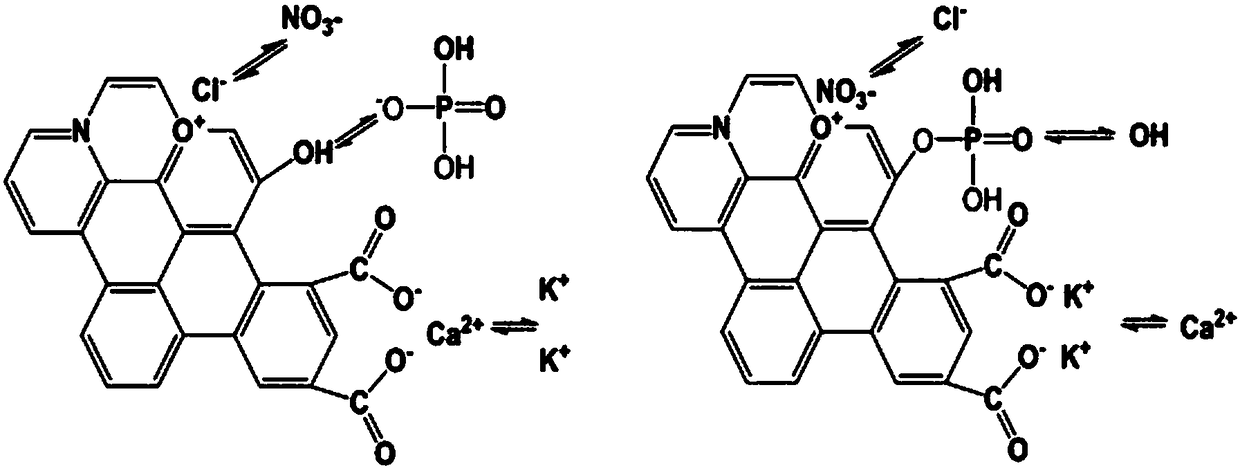

A technology for discarding biomass and organic fertilizers, which is applied in the fields of organic fertilizers, chemical instruments and methods, fertilization devices, etc., can solve the problems of lack of synergy between carbonized straw and fertilizer, lack of functional groups, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Material preparation

[0026] The pig manure was dried and crushed to less than 5mm, and set aside.

[0027] Preparation of carbon-based organic fertilizer

[0028] 1) Mix pig manure (dry basis), water, and quicklime in a ratio of 1:5:1 and put them into a hydrothermal reactor.

[0029] 2) Heating the reactor to 200°C and maintaining it for 60 minutes; cooling by an electric fan and internal circulating cooling water, and then performing solid-liquid separation to obtain hydrothermal charcoal;

[0030] 3) Hydrothermal charcoal and commercial organic fertilizer are mixed according to the ratio of 1:4, and after mechanical stirring for 15 minutes, the charcoal-based organic fertilizer (moisture content 41%, dry basis organic matter 66.2%, TN 1.96%, P 2 o 5 3.12%, K 2 O 2.94%).

[0031] 2. Fertilizer effect experiment design

[0032] Using plot experiment method, each plot is about 10m 2 , two treatments were set up in the experiment, and organic fertilizer and ...

Embodiment 2

[0043] 1. Use corn stalks instead of pig manure.

[0044] The hydrothermal condition in the preparation step of the carbon-based organic fertilizer is: 220° C. for 80 minutes. Hydrothermal charcoal and commercial organic fertilizer were mixed according to the ratio of 1:6, and after mechanical stirring for 15 minutes, the charcoal-based organic fertilizer (water heat content 44%, dry basis organic matter 68.2%, TN 1.83%, P 2 o 5 3.02%, K 2 O 3.09%).

[0045] 2. Peanuts (Fuhua 12) were used instead of rice in the fertilizer effect experiment design, and the planting density was 15 holes / m 2 , 3 plants per hole, sowed on May 28, 2016, and harvested on September 28. Apply organic fertilizer and carbon-based organic fertilizer respectively, the dosage is 3.5kg / m 2 . All organic fertilizers were used as base fertilizers, which were evenly sprinkled and then plowed. The rest of the management measures are the same.

[0046] 3. Fertilizer efficiency test method

[0047] Ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com