Vinyl acetate-vinyl versatate polymer emulsion as well as preparation and application thereof

A technology of vinyl tertiary carbonate and vinyl acetate is applied to vinyl acetate-vinyl tertiary carbonate polymer emulsion and its preparation and application fields, and achieves the effects of less emulsifier dosage, good balance performance and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

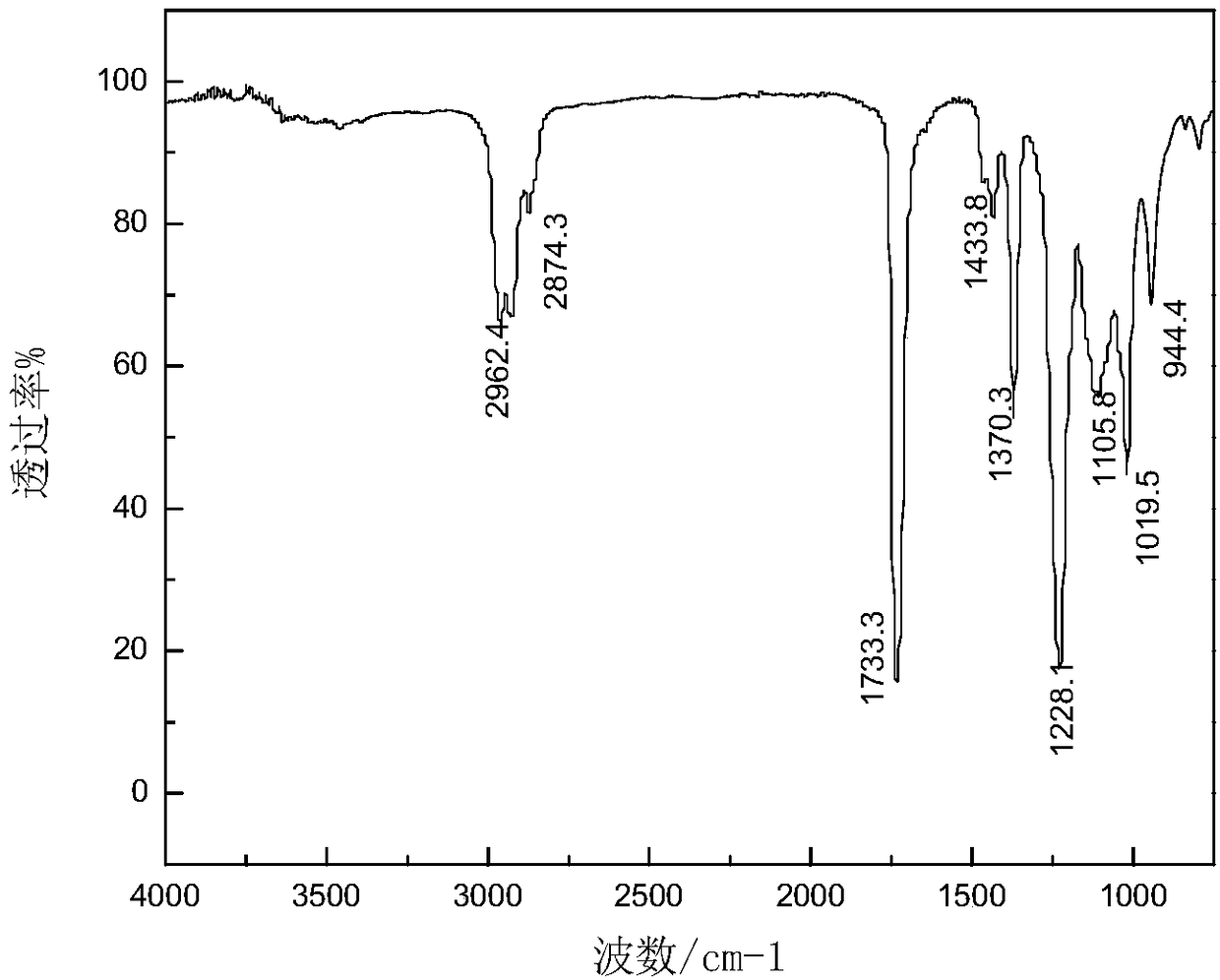

Image

Examples

Embodiment 1

[0027] (1) Formulation:

[0028] Surfactant (hexadecyltrimethylammonium bromide) 0.6%, vinyl acetate monomer 19.3%, vinyl tert-carbonate monomer 8.3%, functional monomer (hexafluorobutyl methacrylate and vinyl Triethoxysilane (1:0.6) 2.4%, initiator (azobisisobutylamidine hydrochloride V50) 0.12%, the balance is deionized water, and the total amount of each component is 100%.

[0029] (2) Preparation method:

[0030] In a 250mL four-necked flask equipped with a stirrer, a reflux condenser, and a dropping funnel, add 0.6g of cetyltrimethylammonium bromide and 39.4g of deionized water, stir and raise the temperature to 65°C in a water bath. Add 3.0 g of mixed monomers and 3.0 g of V50 aqueous solution dropwise within 15 minutes, and continue to keep warm for 30 minutes after the dropwise addition to prepare the seed emulsion. Then the remaining 27.0g V50 aqueous solution and 27.0g mixed monomer were added dropwise to the four-necked flask at a constant speed within 2.0h. The ...

Embodiment 2

[0036] (1) Formulation:

[0037] Surfactant (hexadecyltrimethylammonium bromide and nonylphenol polyoxyethylene ether 2:1) 0.6%, vinyl acetate monomer 22.5%, vinyl tertiary carbonate monomer 7.5%, initiator V500. 09%, functional monomer (hexafluorobutyl methacrylate) 1.5%, the balance is deionized water, and the total amount of each component is 100%.

[0038] (2) Preparation method:

[0039] In a 250mL four-necked flask equipped with a stirrer, a reflux condenser, and a dropping funnel, add 0.4g of cetyltrimethylammonium bromide and 0.2g of nonylphenol polyoxyethylene ether (OP-10) and 39.4g of deionized water, stirred and heated to 65°C in a water bath. Add 3.0 g of mixed monomer and 3.0 g of V50 aqueous solution dropwise within 15 minutes respectively, and continue to keep warm for 15 minutes after the dropwise addition is completed. Then the remaining 27.0g of V50 aqueous solution and 27.0g of mixed monomers were added dropwise into the four-neck flask within 2.0h. Afte...

Embodiment 3

[0044] (1) Formulation:

[0045] Surfactant (cetyl trimethyl ammonium bromide, dodecyl dimethyl benzyl ammonium chloride and nonylphenol ethoxylate 6:1.5:1) 1.7%, vinyl acetate monomer 18.3 %, vinyl tert-carbonate monomer 9.9%, functional monomer (hexafluorobutyl methacrylate and vinyl triethoxysilane 1:1) 1.8%, initiator V50 0.12%, the balance is deionized water , the total amount of each component is 100%.

[0046] (2) Preparation method:

[0047] In a 250mL four-necked flask equipped with a stirrer, a reflux condenser, and a dropping funnel, add 1.2g of cetyltrimethylammonium bromide, 0.3g of dodecyldimethylbenzylammonium chloride and 0.2g of nonylphenol polyoxyethylene ether and 38.3g of deionized water, stirred and heated to 65°C in a water bath, added dropwise 3.0g of mixed monomer and 3.0g of V50 aqueous solution within 15 minutes, and continued to keep warm for 15 minutes after the dropwise addition. Then the remaining 27.0 g of mixed monomer and 27.0 g of V50 aqueo...

PUM

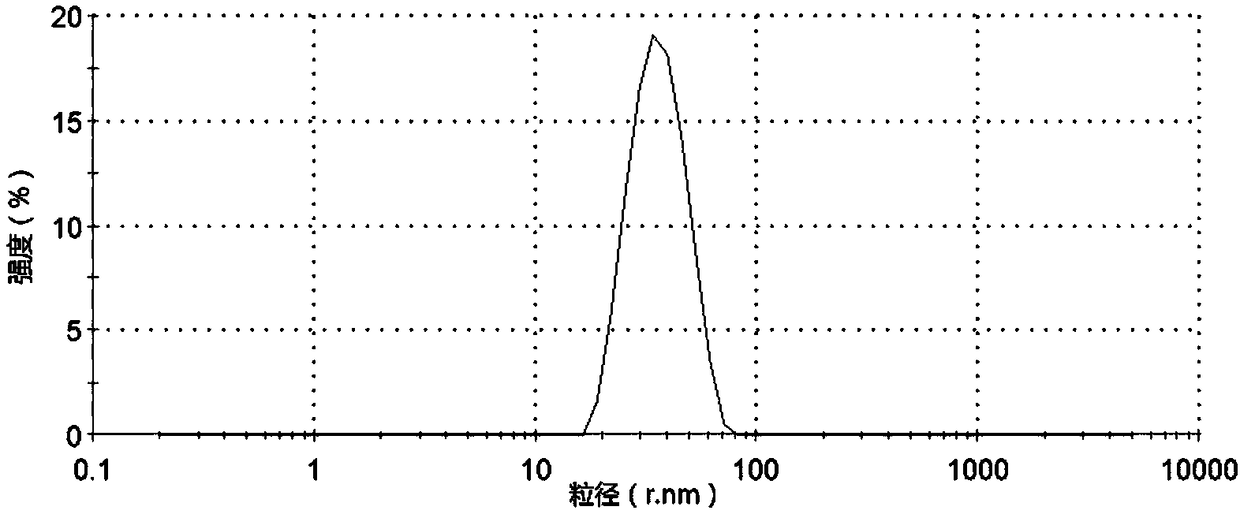

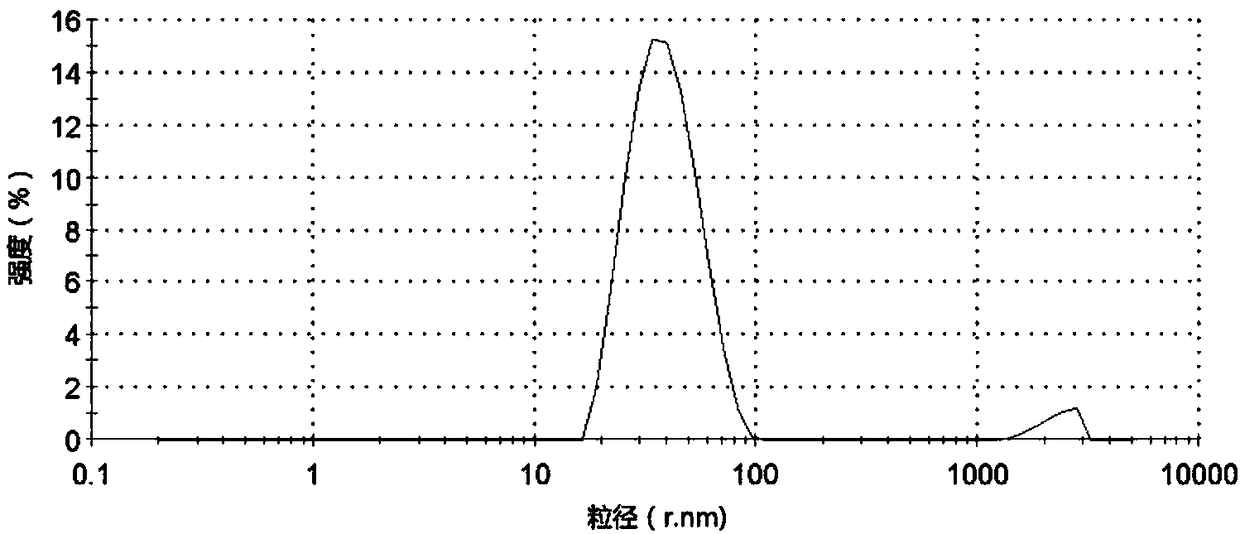

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com