Water-borne polyurethane matte finishing paint for locomotive interior and exterior decorations

A water-based, polyurethane technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of limit film thickness and air bubbles, affect popularization and application, and high raw material prices, so as to reduce product toxicity, excellent water resistance of coatings, Excellent anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

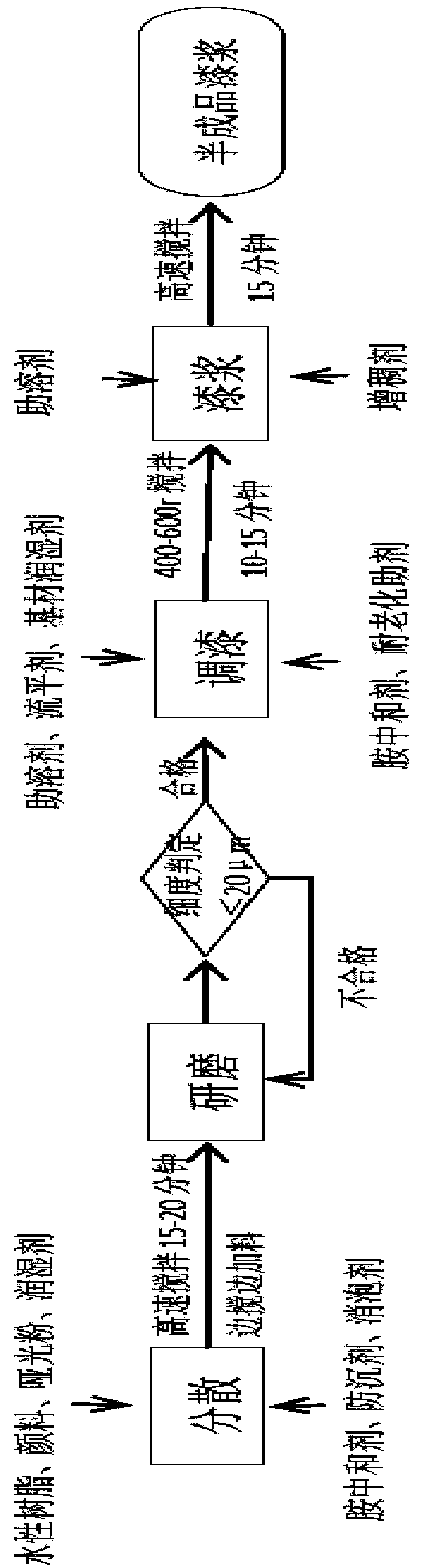

[0177] Two, the preparation method of described locomotive interior and exterior decoration water-based polyurethane matte topcoat comprises the following steps:

[0178] (1), the preparation of described waterborne hydroxyacrylic resin:

[0179] Will

[0180] The water-based hydroxyacrylic acid main resin and the water-based hydroxyacrylic acid auxiliary resin can be mixed uniformly according to the mass ratio main resin: auxiliary resin=53:7;

[0181] (2), the preparation of semi-finished paint paste in the described finish paint:

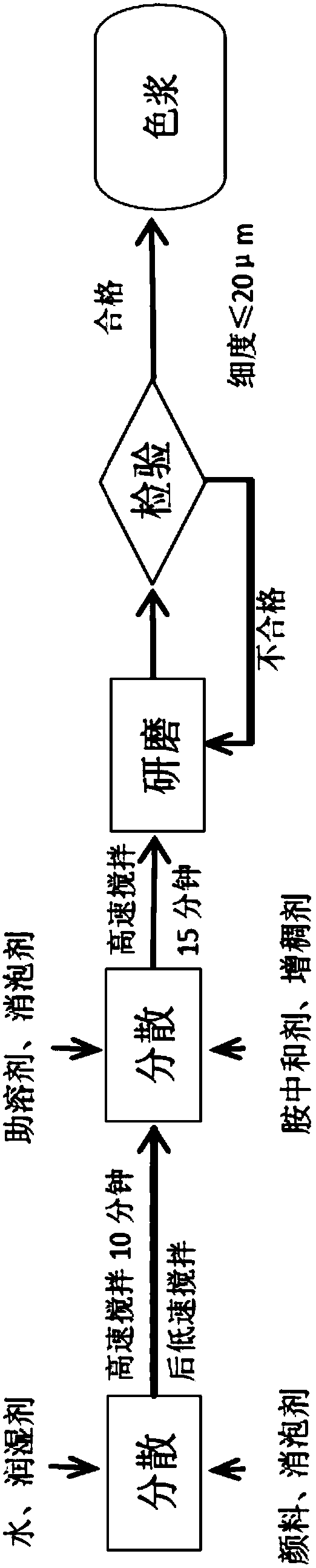

[0182] ①. Preparation of pigment paste:

[0183] Prepare materials according to the pigment paste formula, then pour part of the deionized water and wetting agent into the tank in turn, stir at a low speed of 400 rpm for 3-5 minutes, then add the pigment in the above ratio while stirring, 600-800 rpm Stir at high speed for 10 minutes; then add DPM, anti-sedimentation agent, amine neutralizer, and defoamer in sequence under low-speed stirring, ...

example 1

[0205] Example 1, NCS S0505-Y50R beige water-based polyurethane matte finish

[0206] (1) The parts by weight of the raw materials that make up the topcoat are:

[0207] Ⅰ. Semi-finished paint paste:

[0208] A. Dispersion and grinding

[0209] 42.88 parts of water-based hydroxyacrylic acid main resin 5.66 parts of water-based hydroxyacrylic acid auxiliary resin

[0210] Pigment paste 35.02 parts Amine neutralizer 0.081 parts

[0211] Matte powder 4.05 parts Wetting agent 1.214 parts

[0212] 0.243 parts of anti-settling agent 0.405 parts of defoamer

[0213] Subtotal: 89.55 copies

[0214] Among them, 35.02 parts of pigment paste = 34.53 parts of titanium white paste + 0.0507 parts of iron red paste + 0.437 parts of iron yellow paste + 0.0046 parts of black paste

[0215] B. Letting down

[0216]

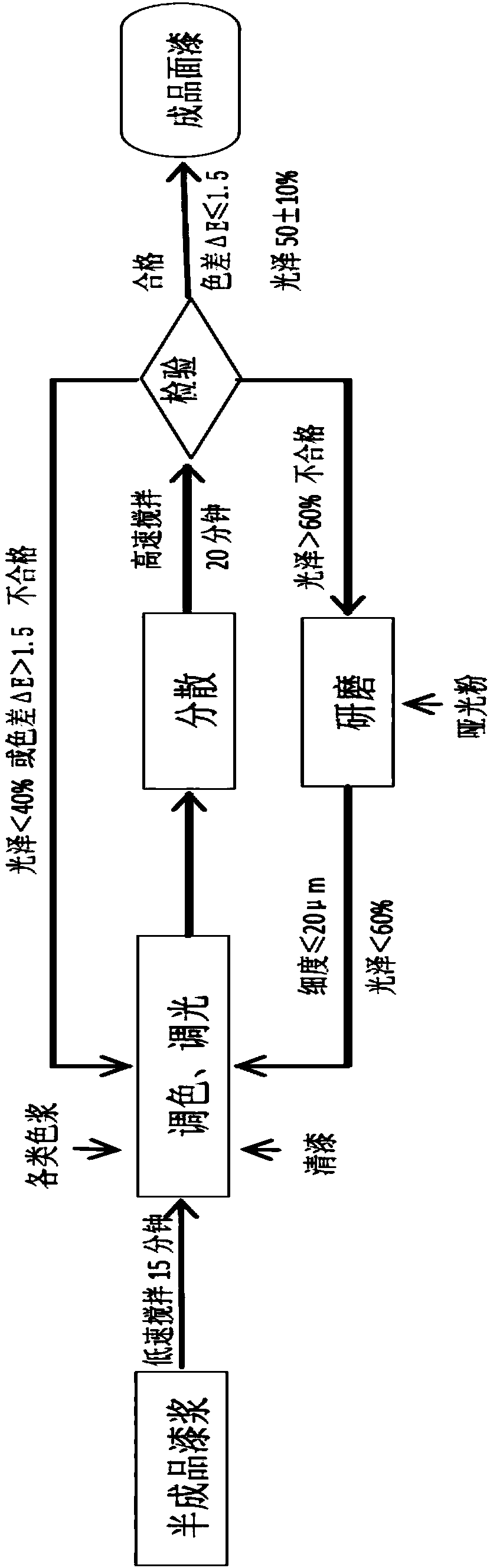

[0217] Ⅱ. Fine-tuning the color difference and gloss of the topcoat:

[0218] Semi-finished paint paste 93.81 parts

[0219] Black pulp 0.0012 parts (according to RAL c...

example 2

[0226] Example 2, RAL7047 ice gray water-based polyurethane matte finish

[0227] (1) The parts by weight of each raw material forming the finish paint are:

[0228] Ⅰ. Semi-finished paint paste:

[0229] A. Dispersion and grinding

[0230]

[0231] Among them, 30.33 parts of pigment paste = 30 parts of titanium white paste + 0.0307 parts of iron red paste + 0.147 parts of iron yellow paste + 0.153 parts of black paste

[0232] B. Letting down

[0233] BCS 2.41 DGBE 5.48

[0234] Leveling agent 0.263 parts Amine neutralizer 0.22 parts

[0235] Substrate wetting agent 0.35 parts Anti-aging additive 1.21 parts

[0236] Thickener 1 1.05 parts Thickener 2 0.35 parts

[0237] Ⅱ. Fine-tuning the color difference and gloss of the topcoat:

[0238] Semi-finished paint paste 93.09 parts

[0239] Black pulp 0.02 parts (according to RAL color card and user negotiation color difference requirements)

[0240] Varnish 6.89 parts (gloss 40-60%, 60° angle gloss meter)

[0241] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com