Rubber wire sheath material and manufacturing method thereof

A sheath material and rubber technology, which is applied in the field of environmentally friendly rubber wire sheath materials and their manufacturing, can solve problems such as harming human health and polluting the environment, and achieve the effects of less pollution, low product toxicity and less precipitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

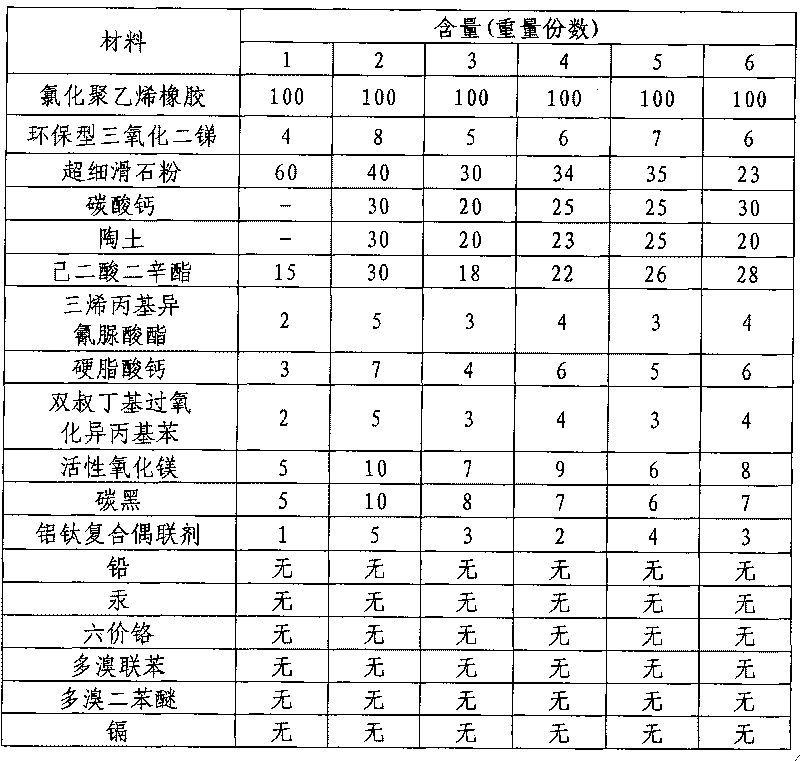

Embodiment 1

[0037] The rubber wire sheath material of the present invention mainly includes chlorinated polyethylene rubber, flame retardant, filler, plasticizer, cross-linking assistant, peroxide cross-linking agent, stabilizer, active agent, reinforcing agent and coupling agent joint agent. The flame retardant is environmentally friendly antimony trioxide; the filler is superfine talc; the plasticizer is dioctyl adipate; the crosslinking aid is triallyl isocyanurate; peroxide crosslinking The agent is di-tert-butyl cumene peroxide; the stabilizer is calcium stearate; the active agent is activated magnesium oxide; the reinforcing agent is carbon black; and the coupling agent is aluminum-titanium composite coupling agent. The contents of the above components are 100 parts of chlorinated polyethylene rubber, 4 parts of environmentally friendly antimony trioxide, 60 parts of ultrafine talc, 15 parts of dioctyl adipate, and 2 parts of triallyl isocyanurate. parts, 2 parts of bis-tert-butyl ...

Embodiment 2

[0046] The rubber wire sheath material of the present invention mainly includes chlorinated polyethylene rubber, flame retardant, filler, plasticizer, cross-linking assistant, peroxide cross-linking agent, stabilizer, active agent, reinforcing agent and coupling agent joint agent. The flame retardant is environmentally friendly antimony trioxide; the filler is a mixture of superfine talc, calcium carbonate and clay; the plasticizer is dioctyl adipate; the crosslinking aid is triallyl isocyanuric acid ester; peroxide cross-linking agent is bis-tert-butyl cumene peroxide; stabilizer is calcium stearate; active agent is activated magnesium oxide; reinforcing agent is carbon black; coupling agent is aluminum-titanium composite couple joint agent. The contents of the above components are 100 parts of chlorinated polyethylene rubber, 8 parts of environmentally friendly antimony trioxide, 40 parts of ultrafine talc, 30 parts of calcium carbonate, 30 parts of clay, 30 parts of diocty...

Embodiment 3

[0055] The rubber wire sheath material of the present invention mainly includes chlorinated polyethylene rubber, flame retardant, filler, plasticizer, cross-linking assistant, peroxide cross-linking agent, stabilizer, active agent, reinforcing agent and coupling agent joint agent. The flame retardant is environmentally friendly antimony trioxide; the filler is a mixture of ultra-fine talc, calcium carbonate and clay; the plasticizer is dioctyl adipate; the cross-linking aid is triallyl isocyanurate acid ester; peroxide cross-linking agent is bis-tert-butyl cumene peroxide; stabilizer is calcium stearate; active agent is activated magnesium oxide; reinforcing agent is carbon black; coupling agent is aluminum-titanium composite coupling agent. The contents of the above components are 100 parts of chlorinated polyethylene rubber, 5 parts of environmentally friendly antimony trioxide, 30 parts of ultrafine talc, 20 parts of calcium carbonate, 20 parts of clay, 18 parts of dioctyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com