Soil conditioner for remediation of Cd/As combined pollution of paddy fields and preparation method thereof

A soil conditioner and compound pollution technology, which is applied in the field of soil conditioner and its preparation, can solve the problems of ecological balance, food quality and safety hazards, serious soil acidification area, and secondary pollution of farmland and cultivated land, so as to prevent damage to human body , Buffer the degree of soil acidification, and improve the effect of acidic soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

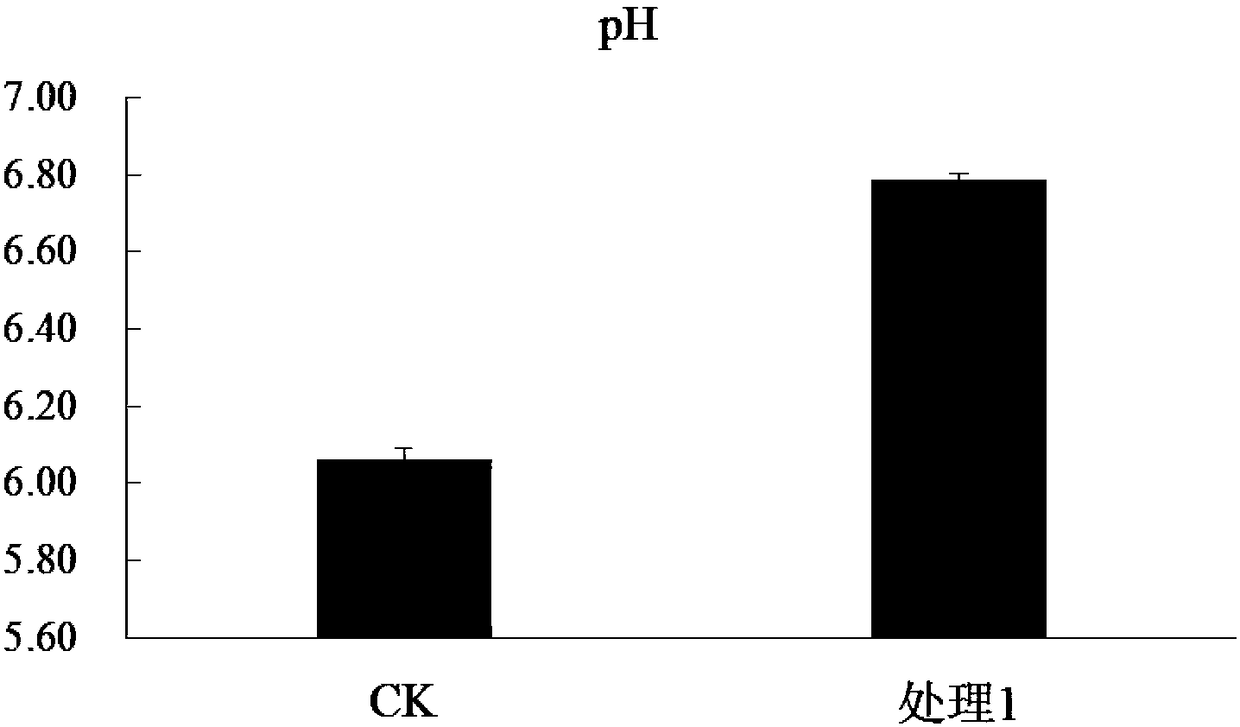

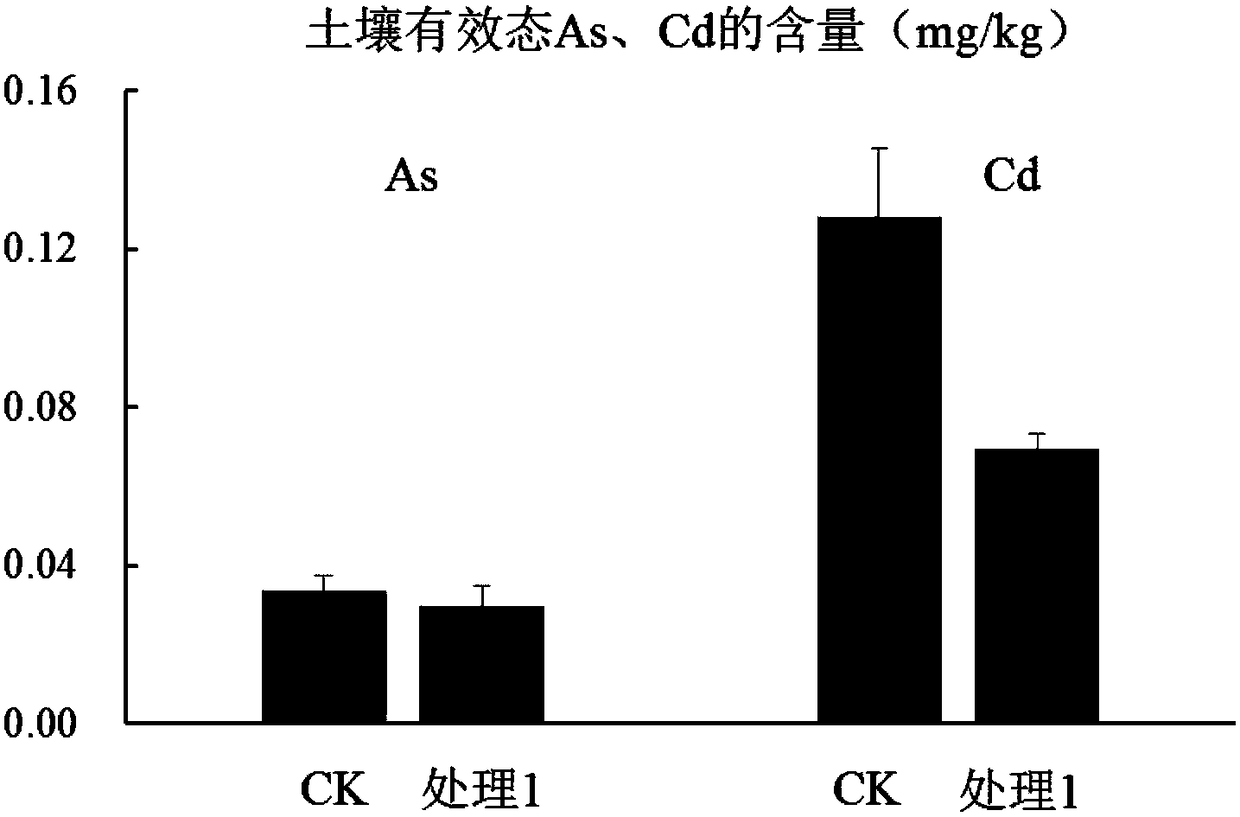

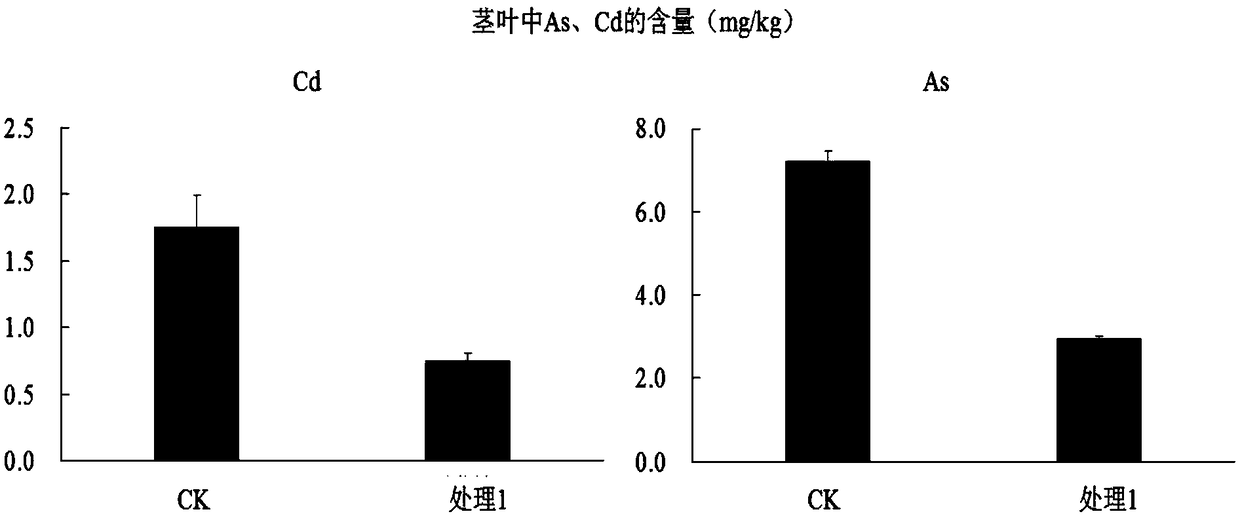

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A soil conditioner of the present invention comprises the following components in parts by mass: 39 parts of polyferric sulfate, 39 parts of activated silicate, 2 parts of ethylenediaminetetraacetic acid disodium salt, and 20 parts of superphosphate. Among them, the disodium salt of ethylenediaminetetraacetic acid is sodium zinc ethylenediaminetetraacetic acid (EDTA-Zn); the activated silicate is prepared by the following method: the silicate mineral and limestone are respectively crushed to 80 mesh, and then mixed evenly , and then calcined at 1000-1100 ° C to obtain activated silicate. The physical and chemical properties of the main components of the soil conditioner are shown in Table 3. The soil conditioner is in the form of mixed granules, and the percentage of granules with a particle diameter of 1mm-5.6mm is not less than 80%.

[0062] The physicochemical property of the main component of soil conditioner in table 3 embodiment 1

[0063]

[0064] The prepar...

Embodiment 2

[0067] A soil conditioner of the present invention comprises the following components in parts by mass: 39 parts of polyferric sulfate, 39 parts of activated silicate, 3 parts of ethylenediaminetetraacetic acid disodium salt, and 19 parts of superphosphate. Among them, the disodium salt of ethylenediaminetetraacetic acid is ethylenediaminetetraacetic acid sodium manganese (EDTA-Mn); the activated silicate is prepared by the following method: the silicate mineral and limestone are respectively crushed to 80 mesh, and then mixed evenly , and then calcined at 1000-1100 ° C to obtain activated silicate. The physical and chemical properties of the main components of the soil conditioner are shown in Table 4. The soil conditioner is in the form of mixed granules, and the percentage of granules with a particle diameter of 1mm-5.6mm is not less than 80%.

[0068] The physicochemical property of the main component of soil conditioner in table 4 embodiment 2

[0069]

[0070]

...

Embodiment 3

[0074] A soil conditioner of the present invention comprises the following components in parts by mass: 38 parts of polyferric sulfate, 38 parts of activated silicate, 4 parts of ethylenediaminetetraacetic acid disodium salt, and 20 parts of superphosphate. Among them, ethylenediaminetetraacetic acid disodium salt is 1 part of ethylenediaminetetraacetic acid sodium zinc (EDTA-Zn) and 3 parts of ethylenediaminetetraacetic acid manganese sodium (EDTA-Mn); the activated silicate is prepared by the following method : The silicate minerals and limestone are respectively crushed to 80 meshes, then mixed evenly, and then calcined at 1000-1100°C to obtain activated silicate. The physical and chemical properties of the main components of the soil conditioner are shown in Table 5. The soil conditioner is in the form of mixed granules, and the percentage of granules with a particle diameter of 1mm-5.6mm is not less than 80%.

[0075] The physicochemical property of the main component of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com