Preparation process for starch self-reinforced composite material applied to hard capsule products

A reinforced composite material and hard capsule technology, which is applied in the field of medicine, can solve the problems of starch gel performance not meeting the capsule production process, starch moisture absorption and poor resistance to high-humidity environment, etc., to achieve excellent resistance to high-humidity environment performance, The effect of preventing starch gelatinization and preventing protein aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

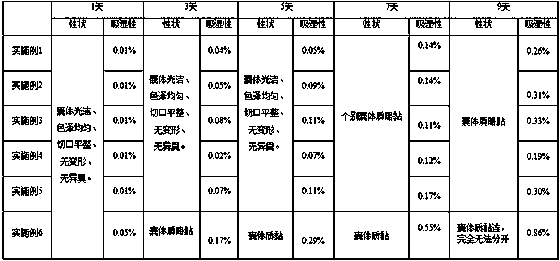

Embodiment 1

[0025] Get the cassava starch 100Kg that the degree of esterification is 0.04, the tapioca starch 2g that amylopectin content is 87%, mix homogeneously.

[0026] Add purified water 0.5 times the mass of the mixture, add medicinal hydrochloric acid dropwise to the container to adjust the pH to 1, and circulate and stir in the container at a speed of 60-80r / min overnight, filter or centrifuge to obtain a solid mixture.

[0027] Add 0.1% Tween 80, 0.01% medicinal sodium hydroxide and 2 times water to the solid mixture.

[0028] Raise the temperature of the mixed material to 80-95° C., heat and stir for 1 hour to obtain a transparent glue solution.

[0029] The glue is degassed in vacuum, cooled to 50-65°C, kept warm for 2-3 hours, dried with hot air at 40-50°C for 24 hours, and crushed through a 100-mesh sieve.

Embodiment 2

[0031] Get the cassava starch 100Kg that degree of esterification is 0.04, the tapioca starch 8g that amylopectin content is 87%, mix homogeneously.

[0032] Add purified water twice the mass of the mixture, add organic acid dropwise to the container to adjust the pH to 2, and circulate and stir in the container at a speed of 60-80r / min overnight, filter or centrifuge to obtain a solid mixture.

[0033] Add 0.05% polyethylene glycol, 0.01% medicinal sodium bicarbonate and 3 times water to the solid mixture.

[0034] Raise the temperature of the mixed material to 80-95° C., heat and stir for 1 hour to obtain a transparent glue solution.

[0035] The glue is degassed in vacuum, cooled to 50-65°C, kept warm for 2-3 hours, dried with hot air at 40-50°C for 24 hours, and crushed through a 100-mesh sieve.

Embodiment 3

[0037] Get the rice starch 100Kg that the degree of esterification is 0.04, the large starch 10g that amylopectin content is 91.9%, mix homogeneously.

[0038] Add purified water twice the mass of the mixture, add organic acid dropwise to the container to adjust the pH to 3, and circulate and stir in the container at a speed of 60-80r / min overnight, filter or centrifuge to obtain a solid mixture.

[0039] Add 0.1% sodium carboxymethylcellulose, 0.02% sodium bicarbonate and 3 times water to the solid mixture.

[0040] Raise the temperature of the mixed material to 80-95° C., heat and stir for 1 hour to obtain a transparent glue solution.

[0041] The glue is degassed in vacuum, cooled to 50-65°C, kept warm for 2-3 hours, dried with hot air at 40-50°C for 24 hours, and crushed through a 100-mesh sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com