Hard capsule prepared through electrostatic spinning and preparation method of hard capsule

A technology of electrospinning and hard capsules, which is used in capsule delivery, pharmaceutical formulations, filament/line forming, etc. It can solve the problems of extreme changes in capsule temperature and water content, unstable thickness, and prone to wrinkling and white spots. problems, to achieve the effect of extended application range and application potential, high porosity and specific surface area, easy adjustment and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

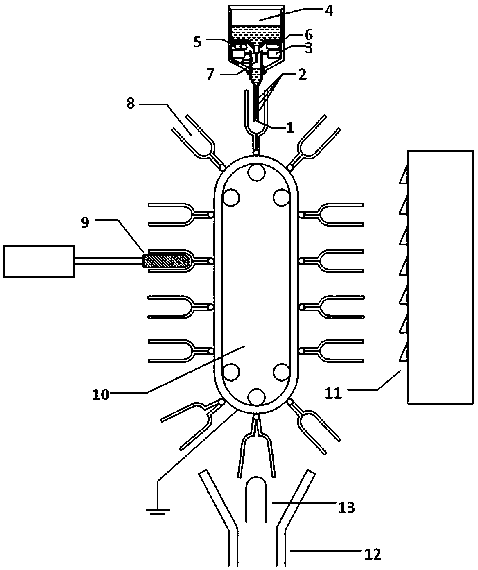

Method used

Image

Examples

Embodiment 1

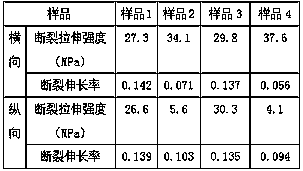

[0028] Embodiment 1-2 is the production embodiment of gelatin capsule embryo, and embodiment 3-4 is the production embodiment of starch capsule embryo, wherein embodiment 1, embodiment 3 are irregular network nanofiber capsule embryo, embodiment 2, embodiment 4 is the nanofiber capsule embryo arranged in parallel.

[0029] Example 1

[0030] 1) Pour the prepared gelatin glue into the storage tank, adjust the temperature control device to maintain the temperature at 65°C, adjust the voltage setting value of the high-voltage power supply device to 1000V, adjust the rotation speed of the nozzle to 30rad / s, and spin The time is set at 1.5min, corn oil is used for the oil brush, the temperature of the drying hair dryer is set at 25±5°C, and the humidity is set at 45%.

[0031] 2) Select the mold with the corresponding shape and type, install it on the main transmission device, the mold is directly grounded through the metal interface on the transmission track, and the embryo body ...

Embodiment 2

[0036] 1) Pour the prepared gelatin glue into the storage tank, adjust the temperature control device to maintain the temperature at 65°C, adjust the voltage setting value of the high-voltage power supply device to 1000V, adjust the rotation speed of the nozzle to 200rad / s, and spin The time is set to 40s, the oil brush uses corn oil, the temperature of the drying hair dryer is set at 25±5°C, and the humidity is set at 45%.

[0037] 2) Select the mold with the corresponding shape and type, install it on the main transmission device, the mold is directly grounded through the metal interface on the transmission track, and the embryo body outlet is placed to contain the goods;

[0038] 3) Start the operation switch of the equipment, start production, and add the gelatin glue in the storage tank in time;

[0039] 4) Close the equipment after production, and clean and maintain the equipment.

[0040] The gelatin capsule sample 2 with parallel arrayed nanofibers was obtained.

Embodiment 3

[0042] 1) Pour the prepared starch glue into the storage tank, adjust the temperature control device to maintain the temperature at 70°C, adjust the voltage setting value of the high-voltage power supply device to 1300V, adjust the rotation speed of the nozzle to 80rad / s, and spin The time is set at 2 minutes, corn oil is used for the oil brush, the temperature of the drying hair dryer is set at 25±5°C, and the humidity is set at 55%.

[0043] 2) Select the mold with the corresponding shape and type, and install it on the main transmission device. The mold is connected to a certain negative voltage through the metal interface on the transmission track, and the embryo body outlet is placed to store the goods;

[0044] 3) Start the operation switch of the equipment, start production, and add the starch glue in the storage tank in time;

[0045] 4) Close the equipment after production, and clean and maintain the equipment.

[0046] Obtain irregular network nanofiber starch capsu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com