Patents

Literature

30results about How to "Outstanding strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

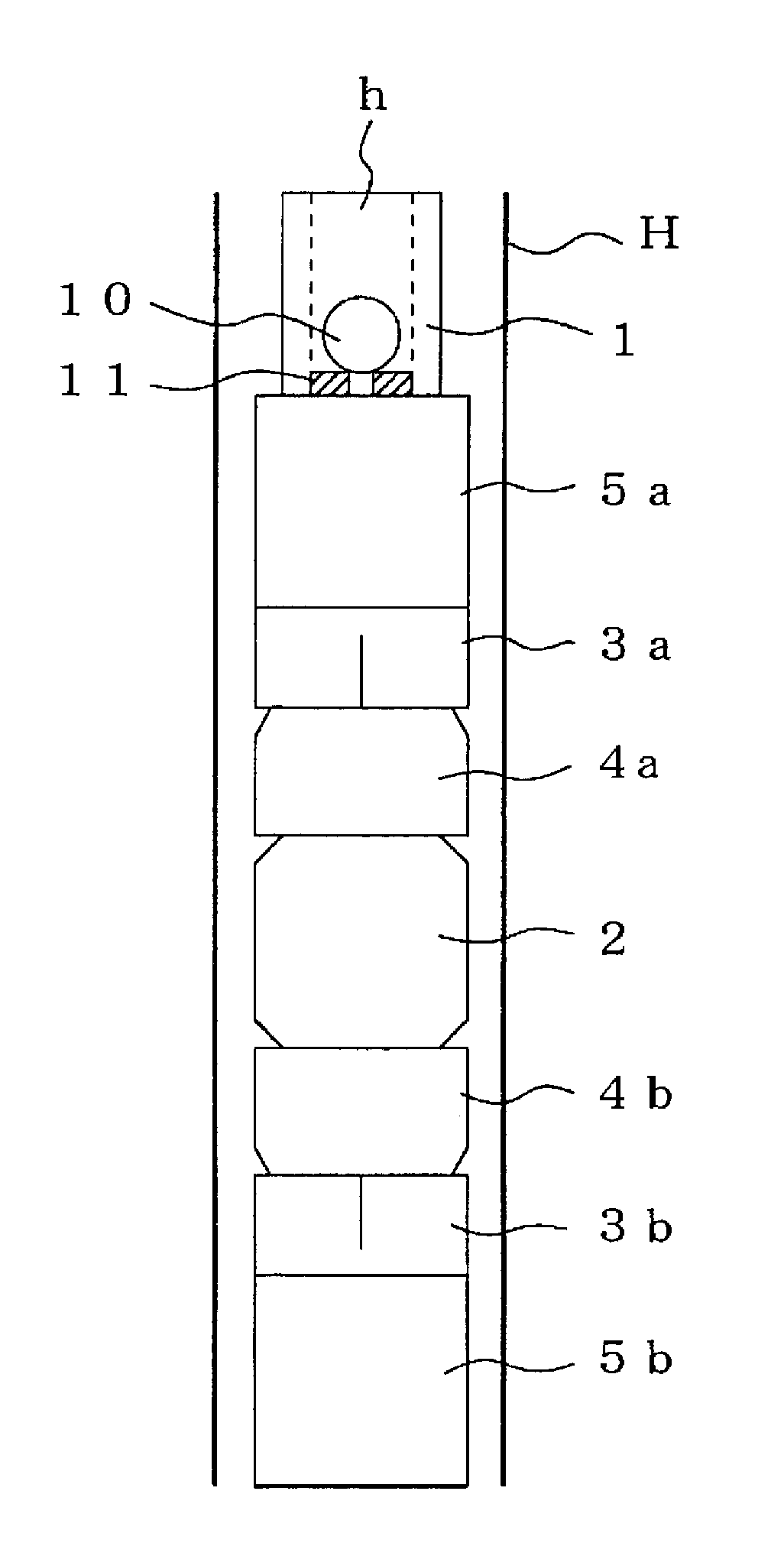

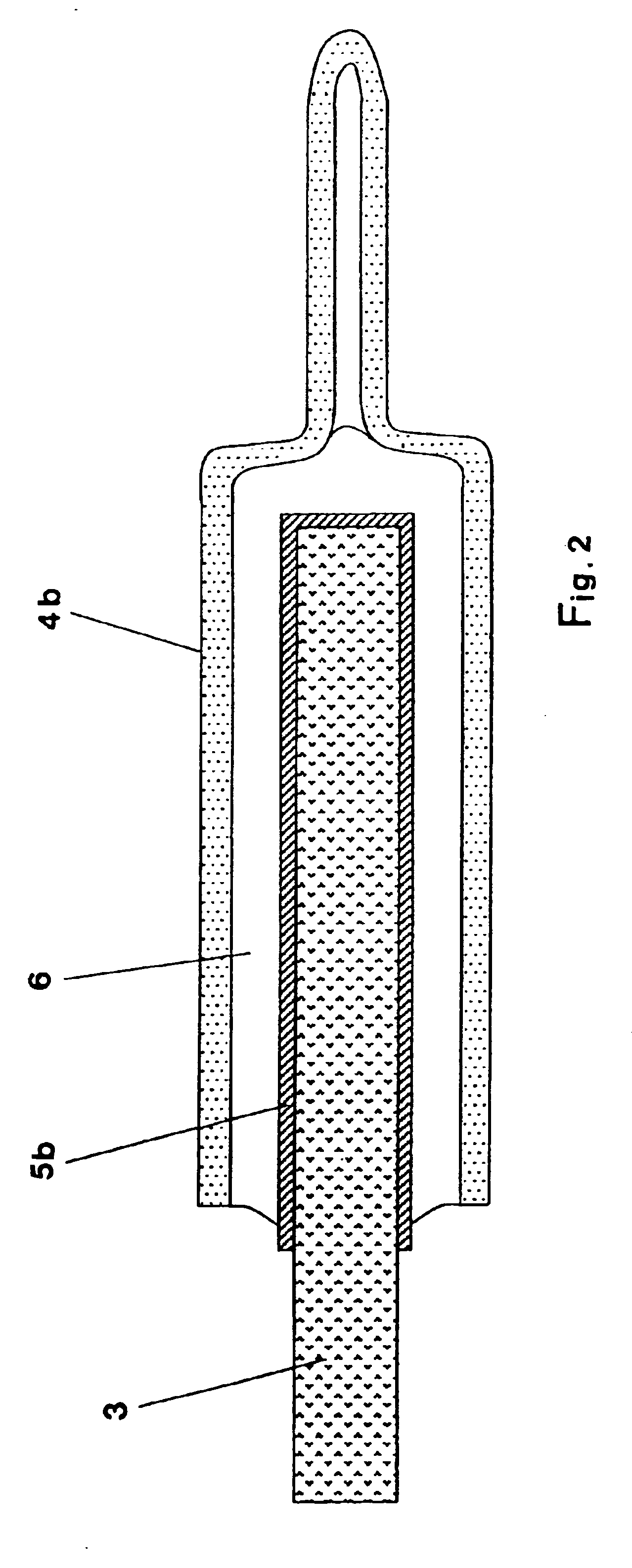

Downhole tool containing downhole-tool member containing reactive metal and downhole-tool member containing degradable resin composition, and well-drilling method

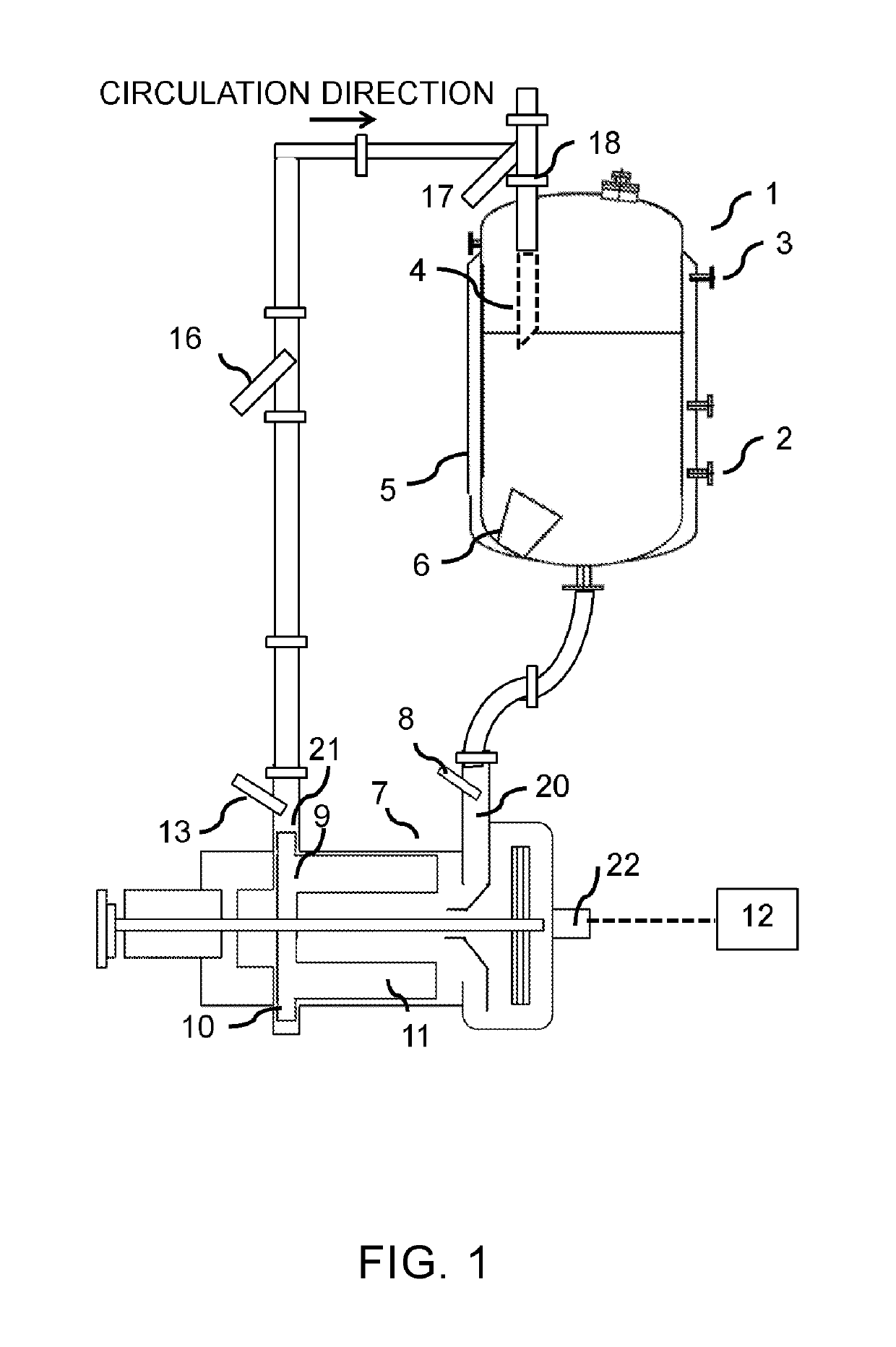

InactiveUS20170284167A1Guaranteed uptimeLow costSynthetic resin layered productsFluid removalWell drillingOrganic matter

A downhole tool, provided with: a downhole-tool member containing a reactive metal; a downhole-tool member containing a degradable resin composition that promotes degradation of the reactive metal, preferably a degradable resin composition containing a degradable resin that generates an acid by degradation or a degradable resin composition containing a degradable resin and an inorganic substance or organic substance that promotes degradation of the reactive metal; and, as desired, a degradable rubber member. Moreover, a well-drilling method using this downhole tool.

Owner:KUREHA KAGAKU KOGYO KK

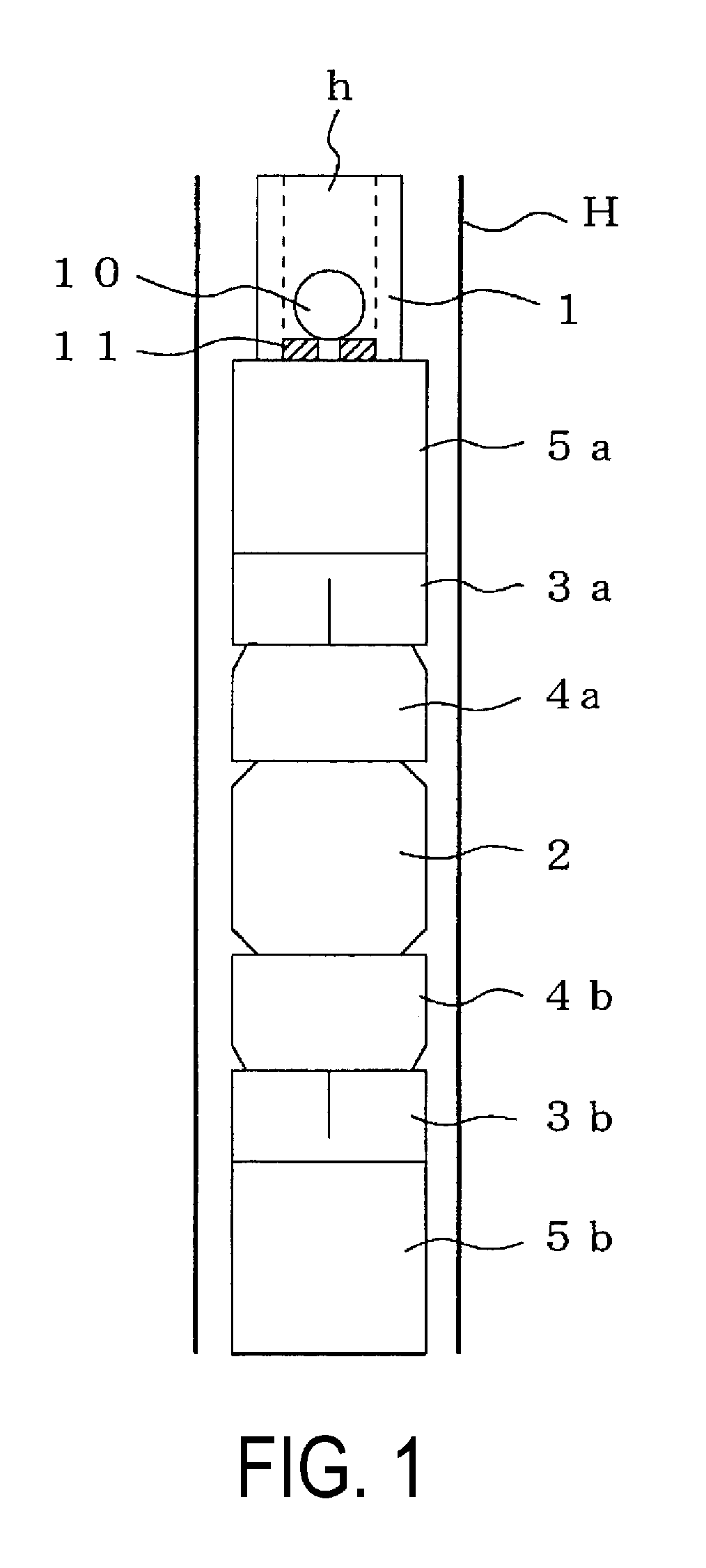

Carbon fiber product, and method of adjusting length of carbon fiber product

InactiveUS7018601B2Improve surface activityImprove adhesionPigmenting treatmentMaterial nanotechnologyFiberCarbon layer

A carbon fiber product according to the present invention is a carbon fiber product in which one to several hundreds of hexagonal carbon layers in the shape of a bottomless cup are stacked. Edges of the hexagonal carbon layers are exposed on at least part of an outer surface or inner surface. The exposed part of the edges of the hexagonal carbon layers have a high degree of activity and excel in adhesion to base materials such as resins. Therefore, this carbon fiber product is suitable as a material for composites.

Owner:GSI CREOS CORP +1

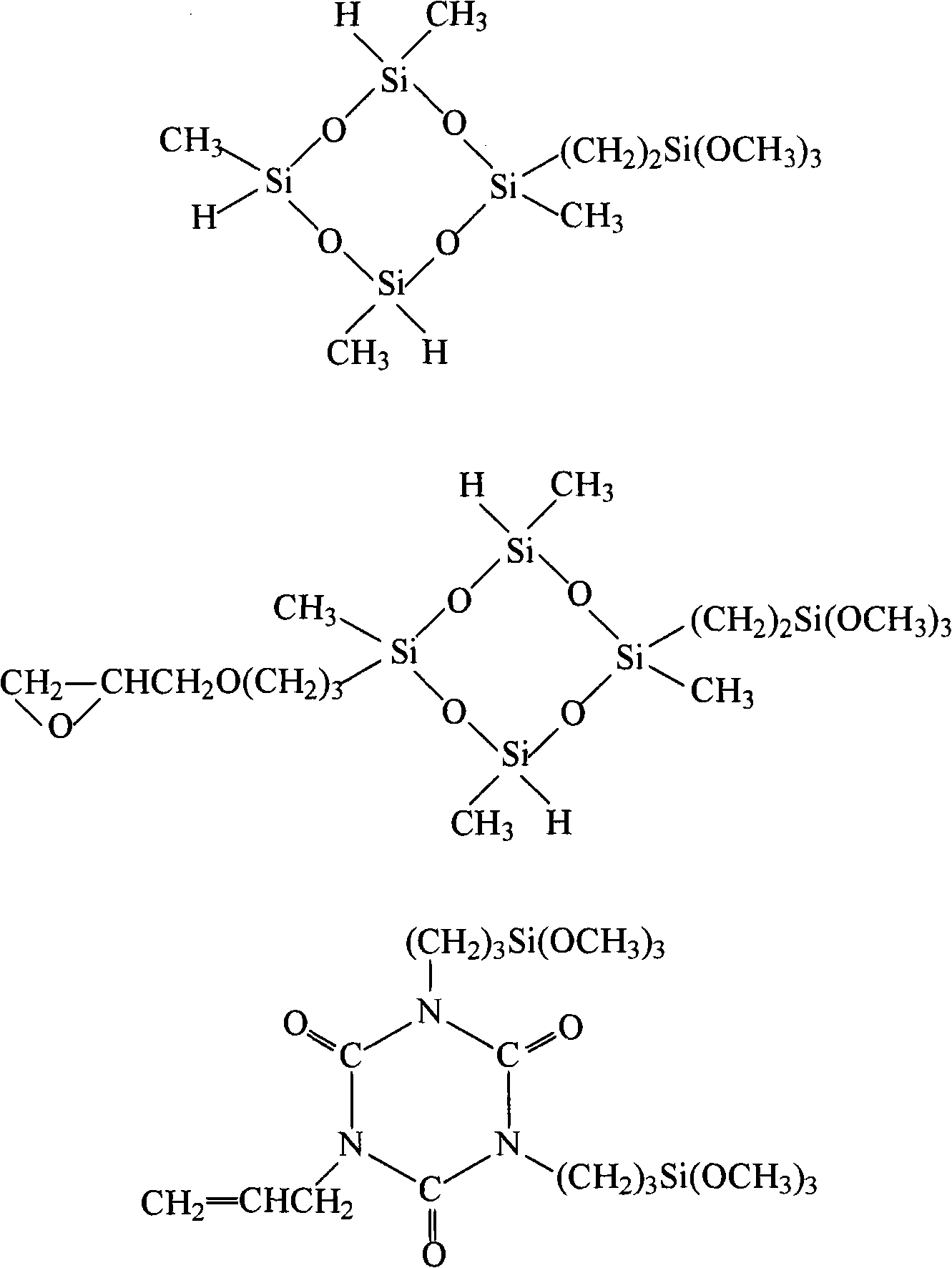

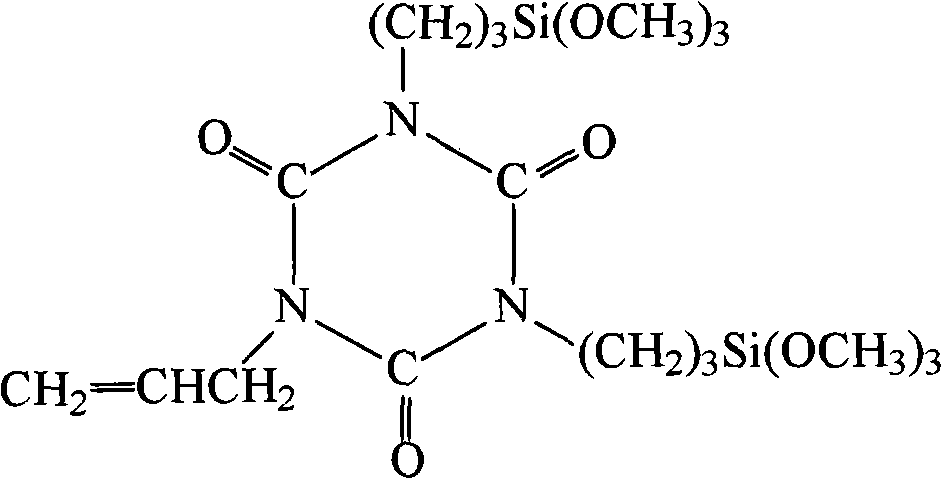

Heat-conductive silicone rubber composite sheet

InactiveCN101954766AImprove thermal conductivityExcellent thermal conductivitySolid-state devicesCoatingsAlkoxy groupSynthetic resin

A heat-conductive silicone rubber composite sheet having excellent electrical insulation properties, superior strength and flexibility, excellent interlayer adhesion, and particularly favorable thermal conductivity is provided. The composite sheet includes a laminated structure comprising an inner layer and a pair of outer layers laminated to both surfaces of the inner layer. The inner layer is an electrically insulating synthetic resin film layer having a thermal conductivity of not less than 0.3 W / mK, and the outer layers are silicone rubber layers formed by curing a composition including (a) an organopolysiloxane, (b) a curing agent, (c) a heat-conductive filler, and (d) a silicon compound-based adhesion promoter having at least one group selected from the group consisting of an epoxy group, alkoxy groups, a methyl group, a vinyl group, and a group represented by the formula Si-H.

Owner:SHIN ETSU CHEM IND CO LTD

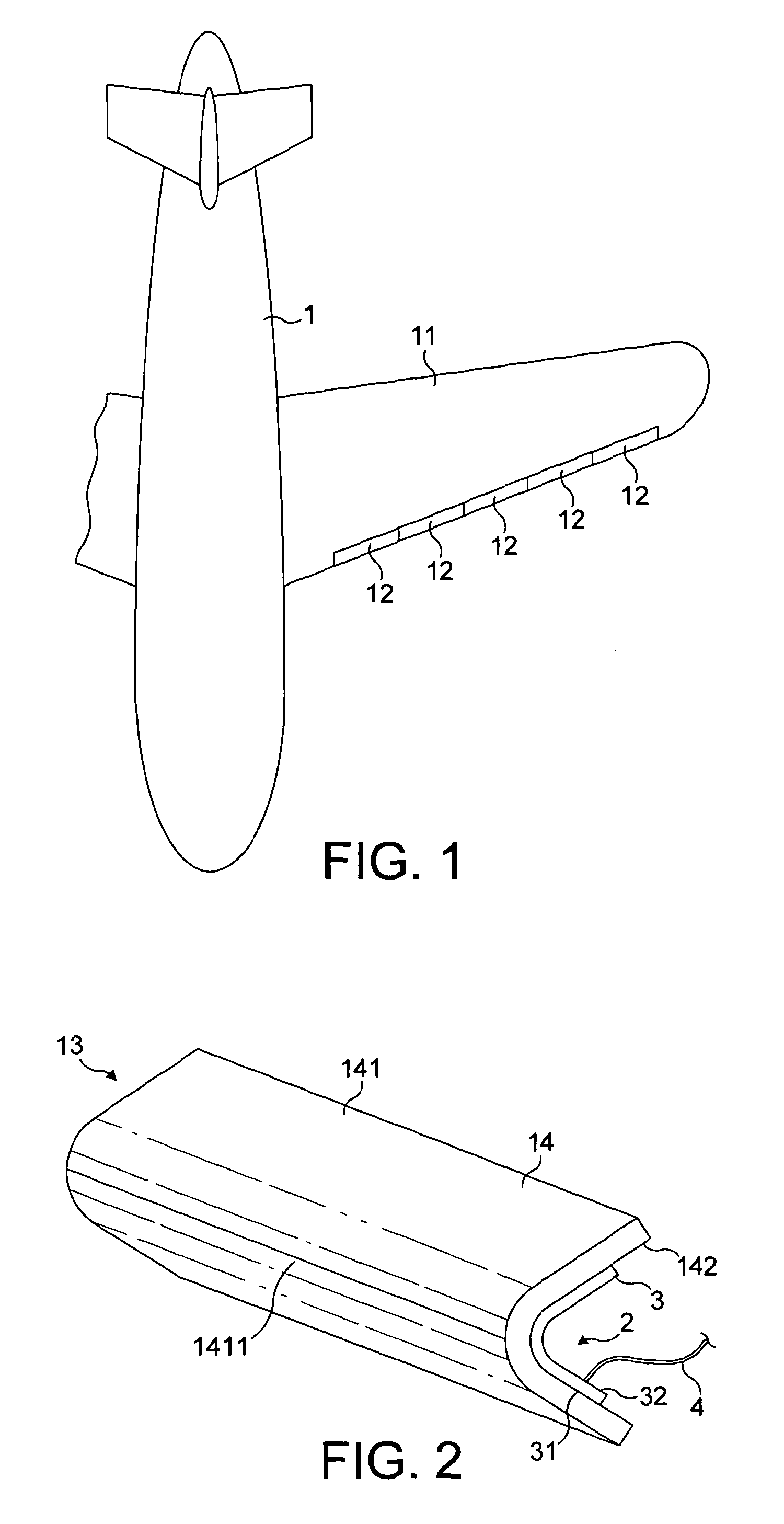

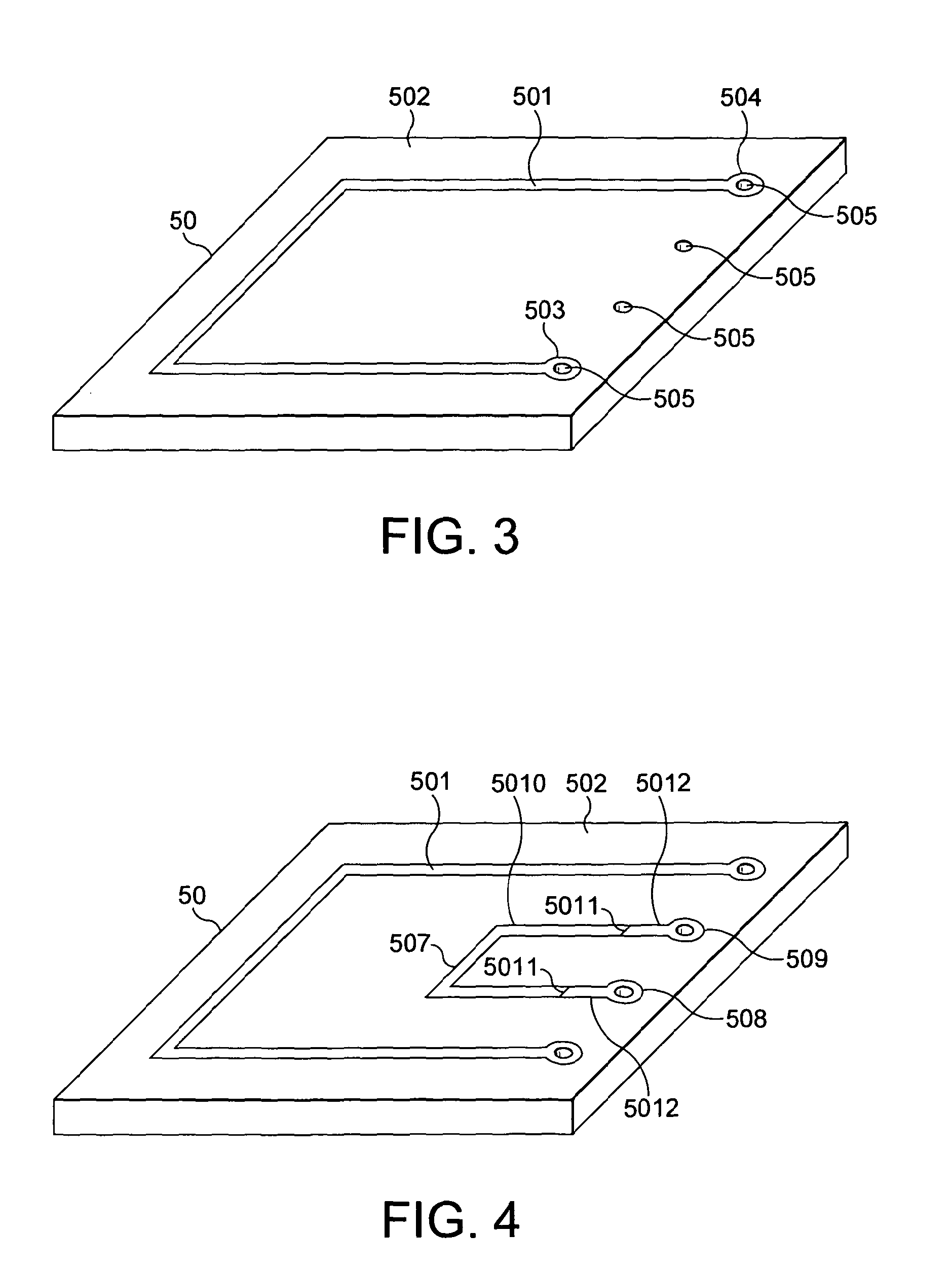

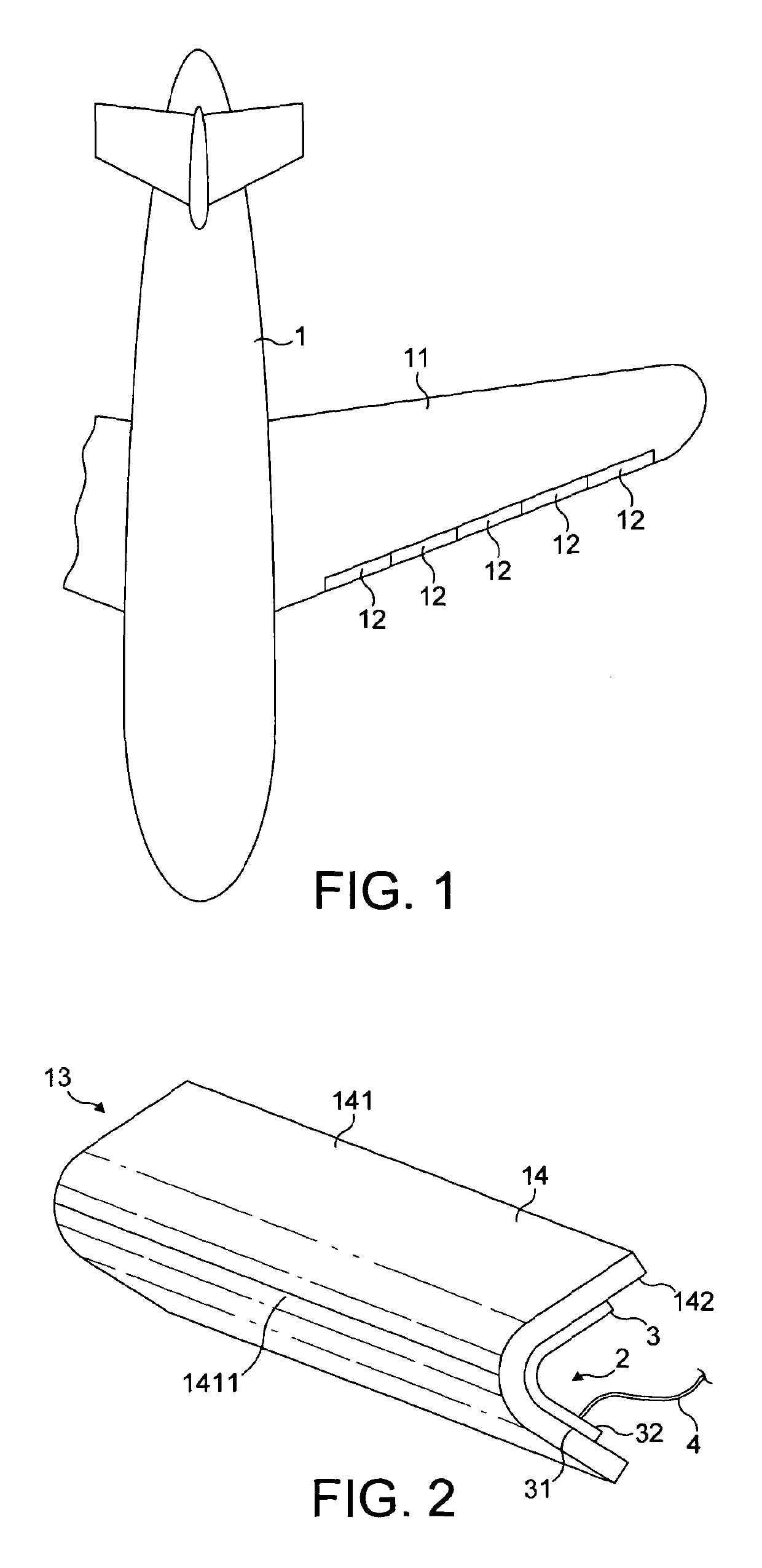

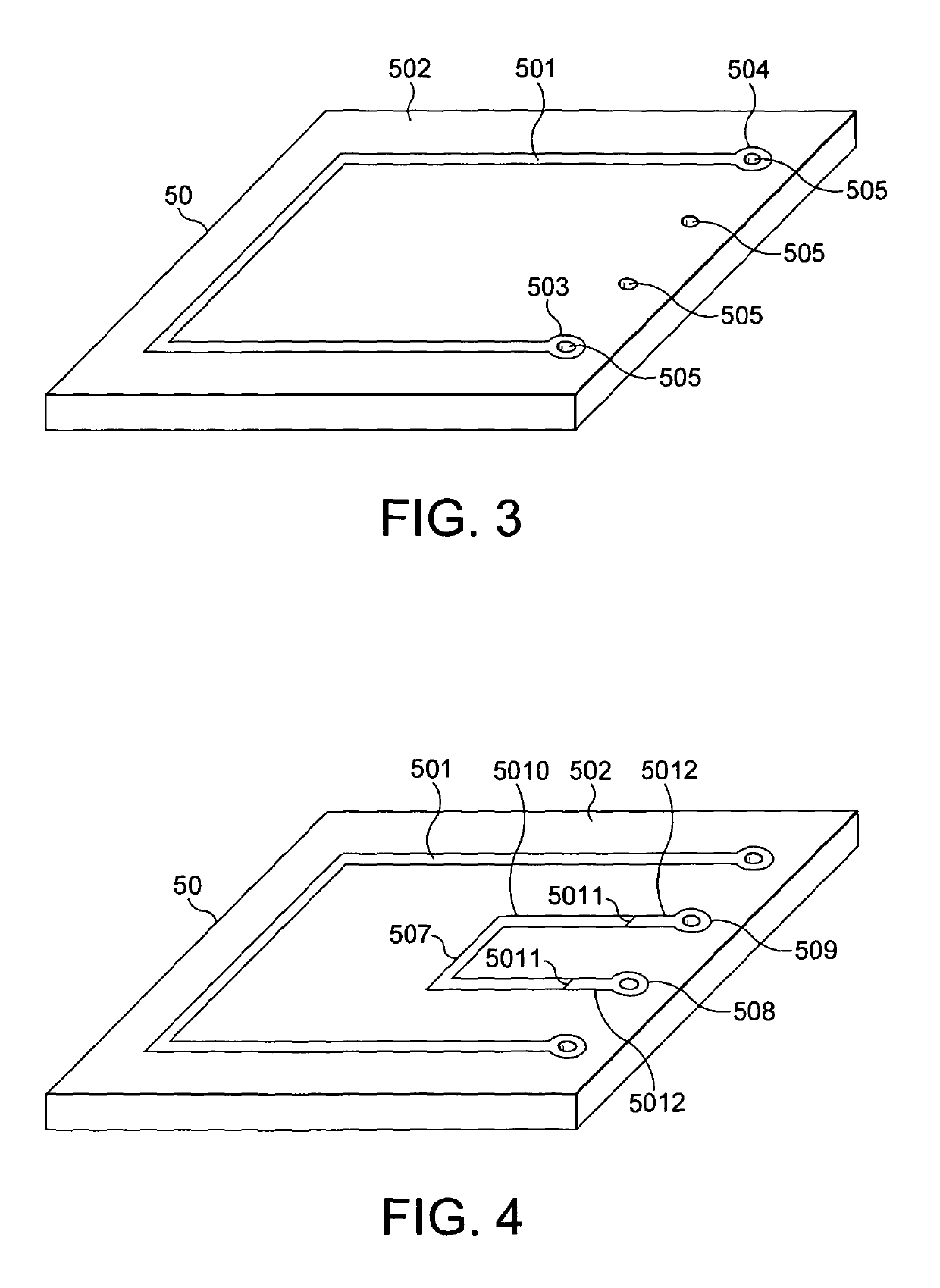

Electrothermal heater mat

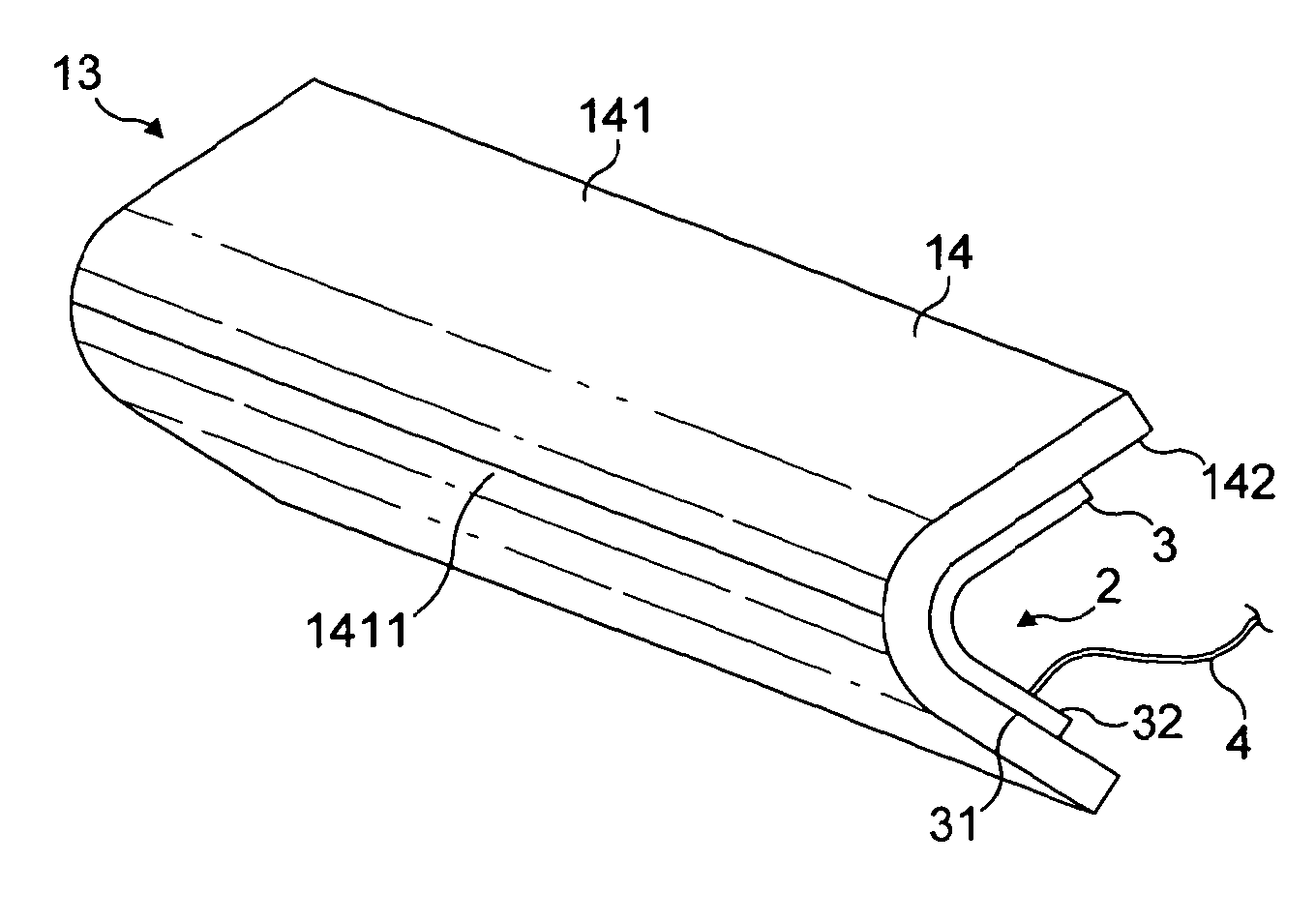

ActiveUS20130001211A1Optimises strength of laminationReduce riskPower plant arrangements/mountingDe-icing equipmentsIce protection systemGround plane

An electrothermal heater mat (3) is provided for an ice protection system for an aircraft (1) or the like. The heater mat (3) is a laminated heater mat and comprises dielectric layers (50-58), a heater element (501) and a conductive ground plane (71-74) for detecting a fault with the heater element (501). The dielectric layers (50-58) are made of thermoplastic material, and the ground plane (71-74) is formed by spraying metal such as copper onto the thermoplastic material of one of the dielectric layers.

Owner:GKN AEROSPACE SERVICES LTD

Toner and method for producing the toner

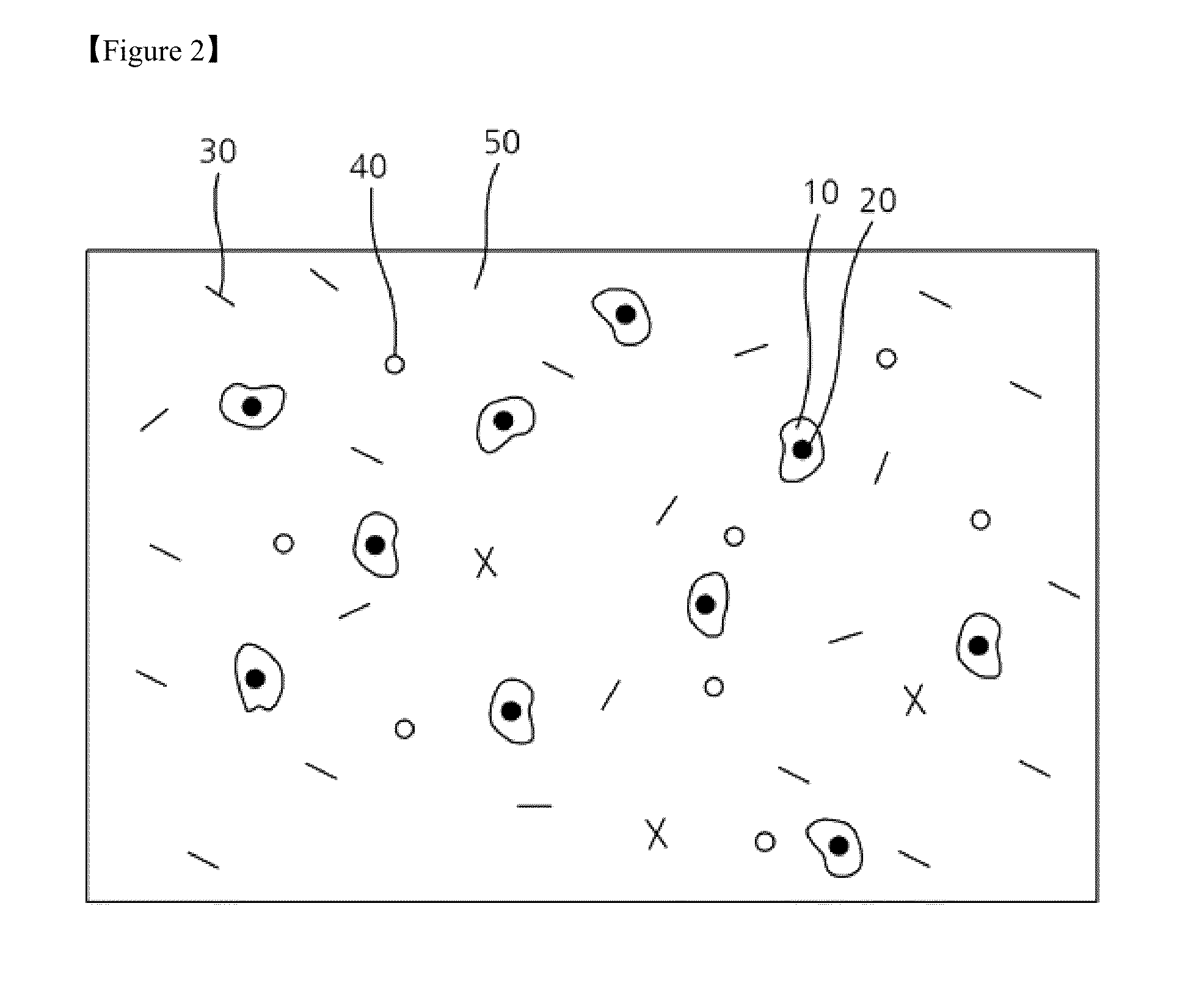

A toner has a toner particle including a binder resin, a colorant, and a wax, in which in a cross section of the toner particle observed under a scanning transmission electron microscope, a proportion of the number of toner particles having a void with a long diameter of 0.50 μm or less is 60 number % or more, and a proportion of the number of toner particles having a void in a region from an outline of the cross section of the toner particle inward to 1.00 μm in a total number of the toner particles having a void is 30 number % or less.

Owner:CANON KK

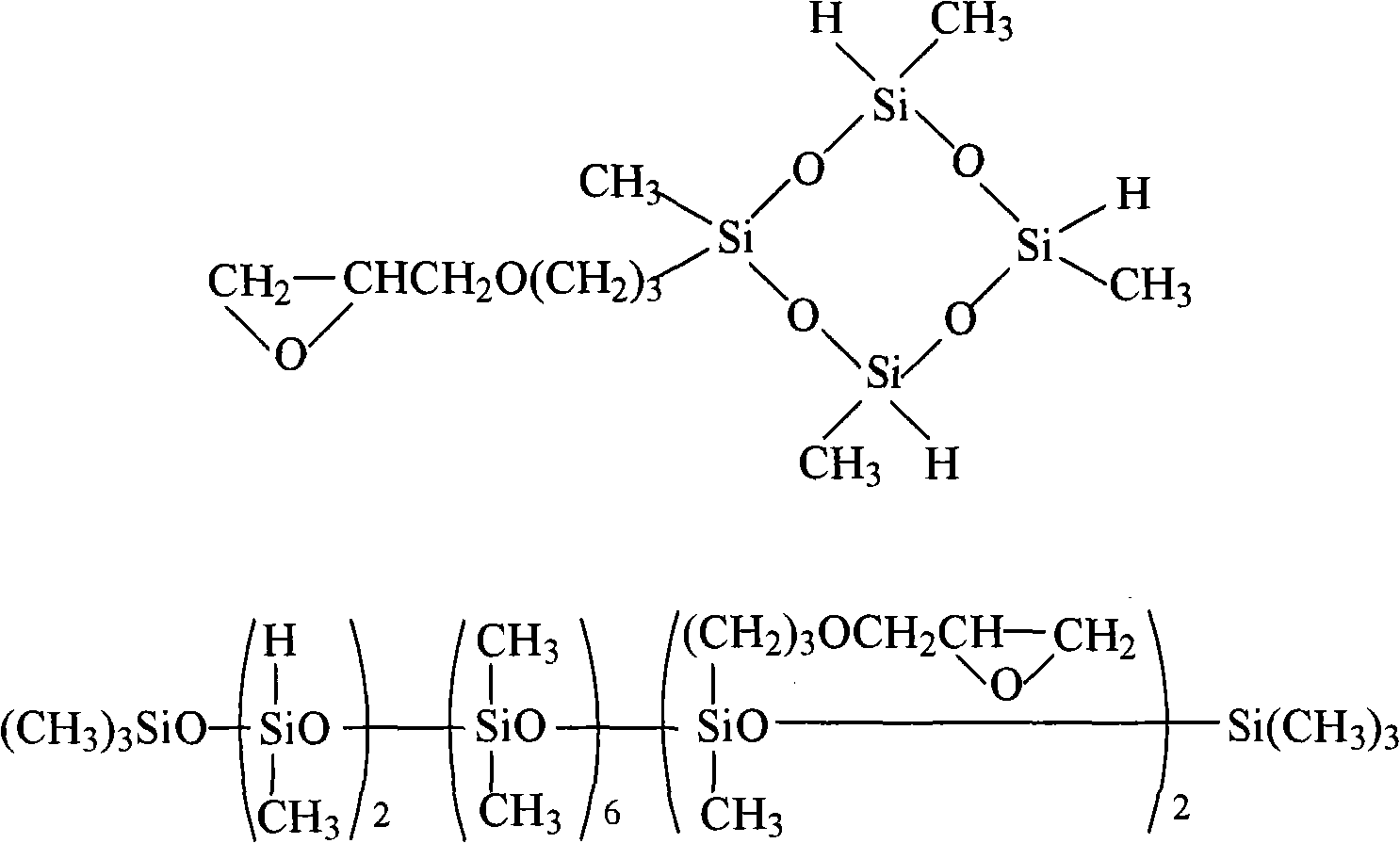

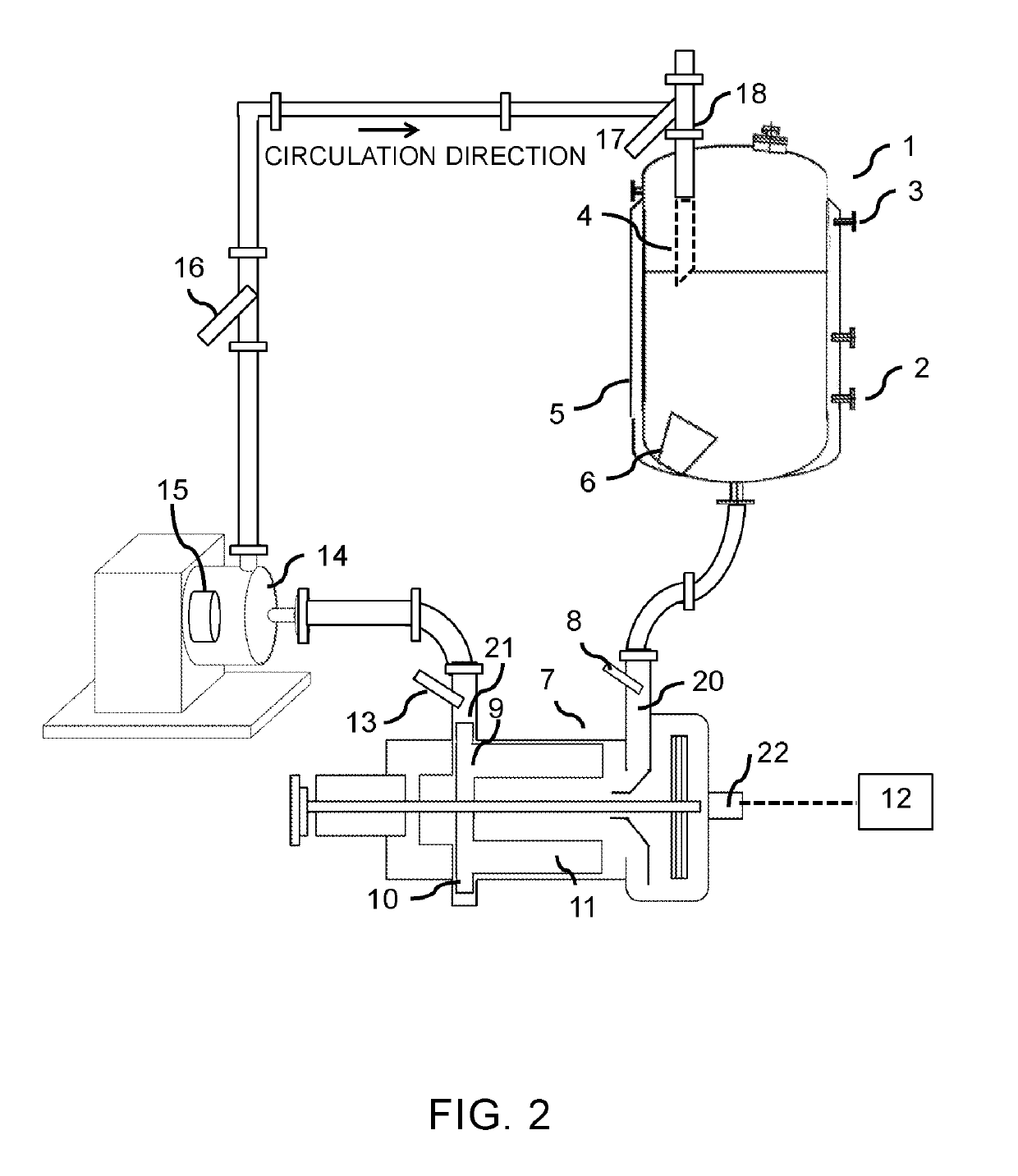

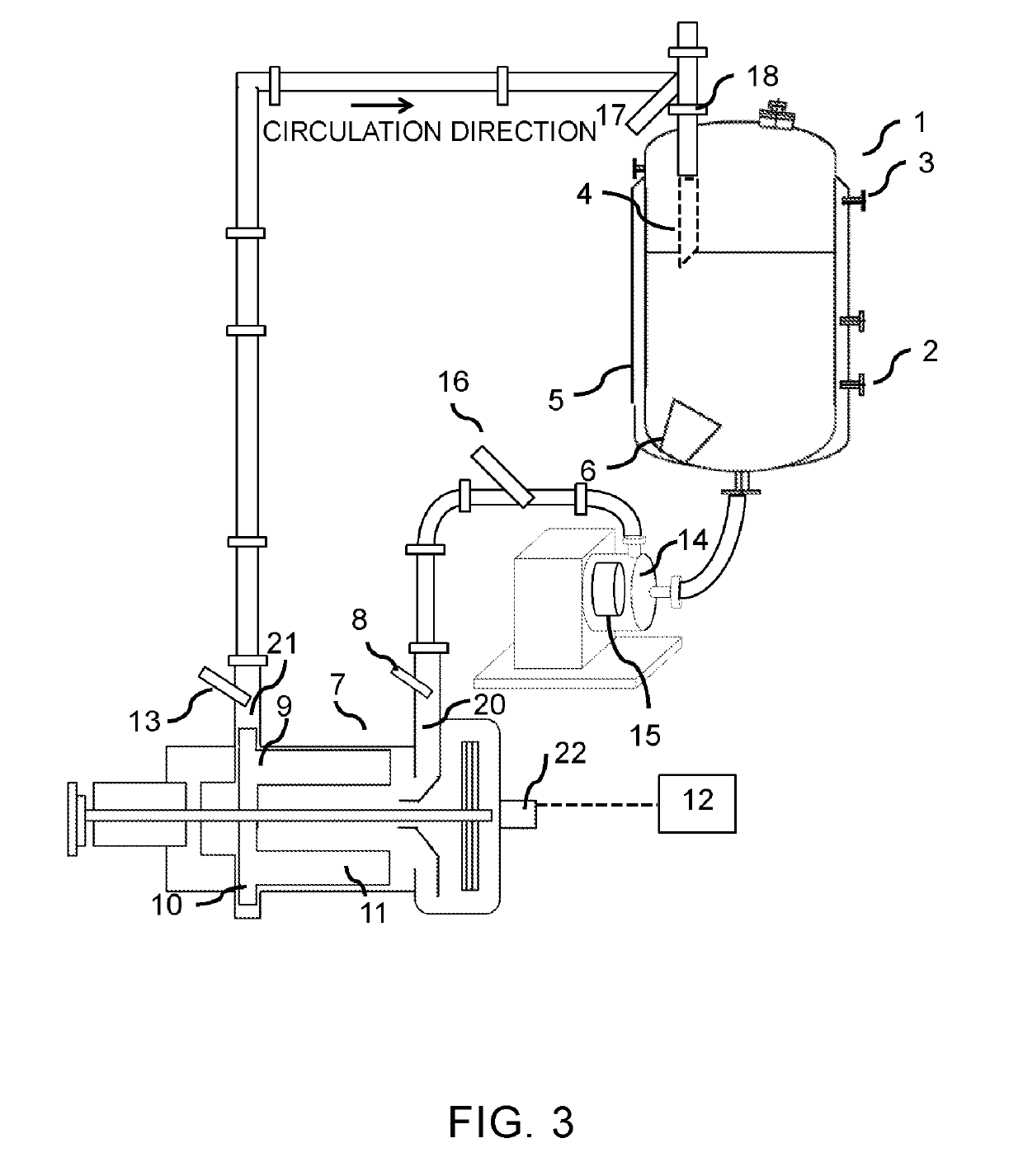

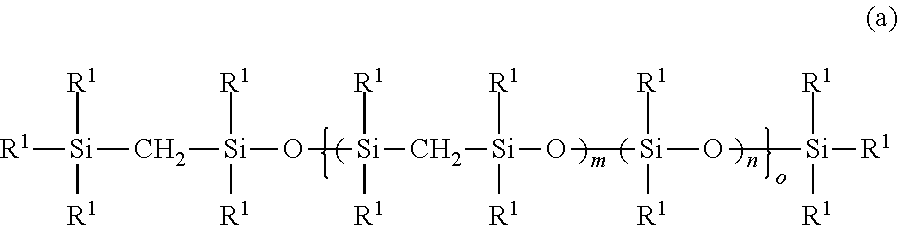

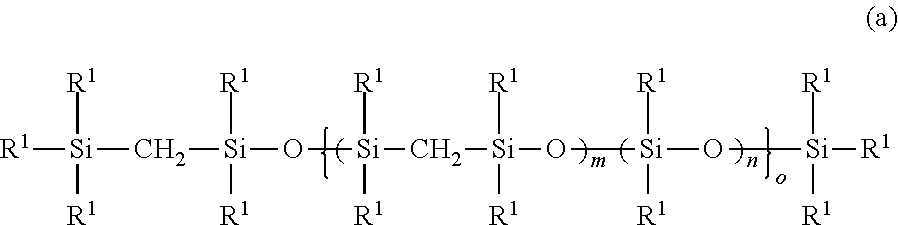

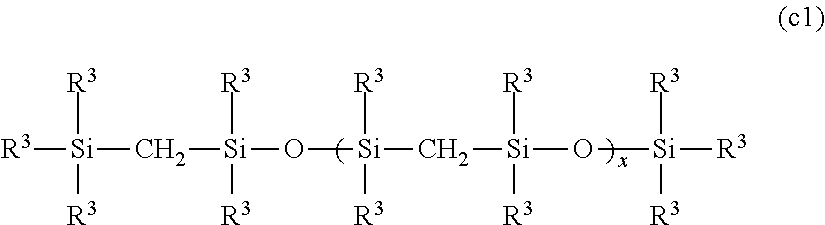

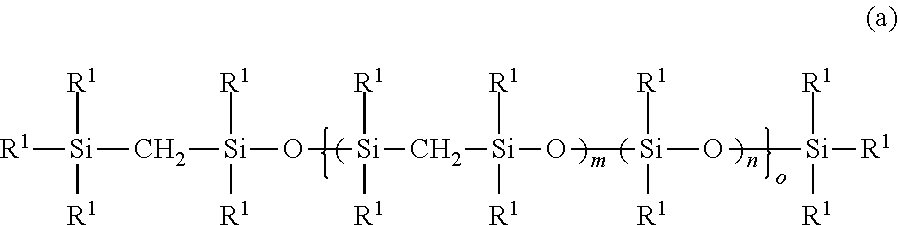

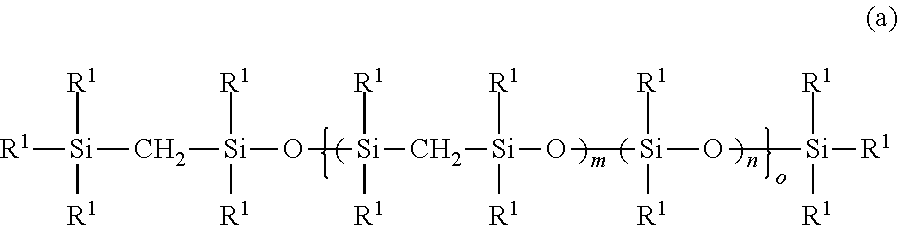

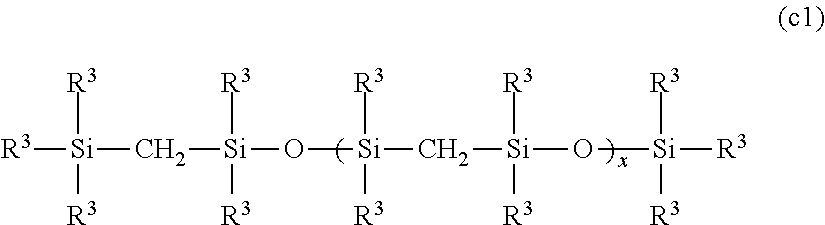

Addition reaction-curable organopolysilmethylenesiloxane copolymer composition

Disclosed is an addition reaction-curable organopolysilmethylenesiloxane copolymer composition including: (A) an organopolysilmethylenesiloxane copolymer represented by formula (a) shown below:which has in one molecule at least two alkenyl groups bonding to silicon atoms; (B) an organopolysiloxane represented by formula (b) shown below:R2aSiO(4-a) / 2 (b)which has in one molecule at least two alkenyl groups bonding to silicon atoms; (C) an organohydrogenpolysilmethylenesiloxane and / or organohydrogenpolysiloxane; and (D) a platinum group metal-based catalyst.The copolymer composition excels in heat resistance, electrical insulation, mechanical strength, and optical properties, and exhibits good water resistance, hydrolysis resistance and gas barrier properties under severe use conditions without suffering gas permeability and poor chemical resistance inherent in silicone rubber.

Owner:SHIN ETSU CHEM IND CO LTD

Production process of thermoplastic elastomer rail pad

ActiveCN103753754AAmazing resilienceExcellent toughnessCoatingsThermoplastic elastomerProduction drawing

The invention provides a production process of a thermoplastic elastomer rail pad, and belongs to the technical field of railway fittings. The production process comprises the following steps: (1) drying raw materials, namely, adding rubber to a dryer to dry for at least two hours under drying temperature of 110 to 130 DEG C; (2) injection molding, namely, performing injection molding through an injection molding machine, adding the dried raw material to a material barrel of the injection molding machine for heating, and then closing a die, injecting, maintaining the pressure, cooling, and opening the die to finish injection molding; (3) cutting nozzles, namely, moving the product subjected to injection molding from a die cavity, and removing burr through a nozzle cutting machine so as to meet the requirements of a production drawing and product technology; and (4) examining and testing, namely, warehousing qualified thermoplastic elastomer rail pads. With the adoption of the production process, the produced thermoplastic elastomer rail pad is stable in structure, small in plastic change, and small in elastic deformation under heavy load, reaches 300 to 500kN / mm of static stiffness, has service life longer than that of a steel rail, realizes stable line and driving safety, and also enables the reduction of the cost of repair and maintenance.

Owner:浙江中元铁路配件有限公司

Phenolic resin molding material and resin sliding part

InactiveUS20070060701A1Outstanding dimensional accuracyOutstanding heat resistanceSynthetic resin layered productsPHENOL LIQUIDFilling materials

A phenolic resin molding material, comprising blending 350 to 900 parts by mass of an inorganic filler with 100 parts by mass of a phenolic novolakin that a total content of a monomeric phenol and a dimeric phenol is 10% or less when measured by the area method of gel filtration chromatography and a degree of dispersion (Mw / Mn) of a weight-average molecular weight (Mw) and a number-average molecular weight (Mn) is 1.1 to 3.0 when measured by gel filtration chromatography, and excelling in moldability, heat resistance, dimensional accuracy and mechanical strength.

Owner:ASAHI YUKIZAI KOGYO CO LTD

Infrared radiation source

InactiveUS6943362B2FavorableOutstanding conductivityOptical radiation measurementDomestic stoves or rangesElectrical conductorElectrical connection

An infrared radiation source has a radiation-transparent, gas-tight tube made of electrically insulating material, in which a heat conductor made of carbon strip is arranged. The heat conductor has two ends, which are respectively electrically and mechanically connected to bushings made of molybdenum and / or tungsten and / or tantalum, and the bushings are respectively connected via current feed-through leads with electrical connections projecting from the tube. The two ends of the heat conductor are respectively connected to one of the bushings by a metallic solder, which contains at least one of the metals titanium, zirconium or hafnium.

Owner:HERAEUS NOBLELIGHT GMBH

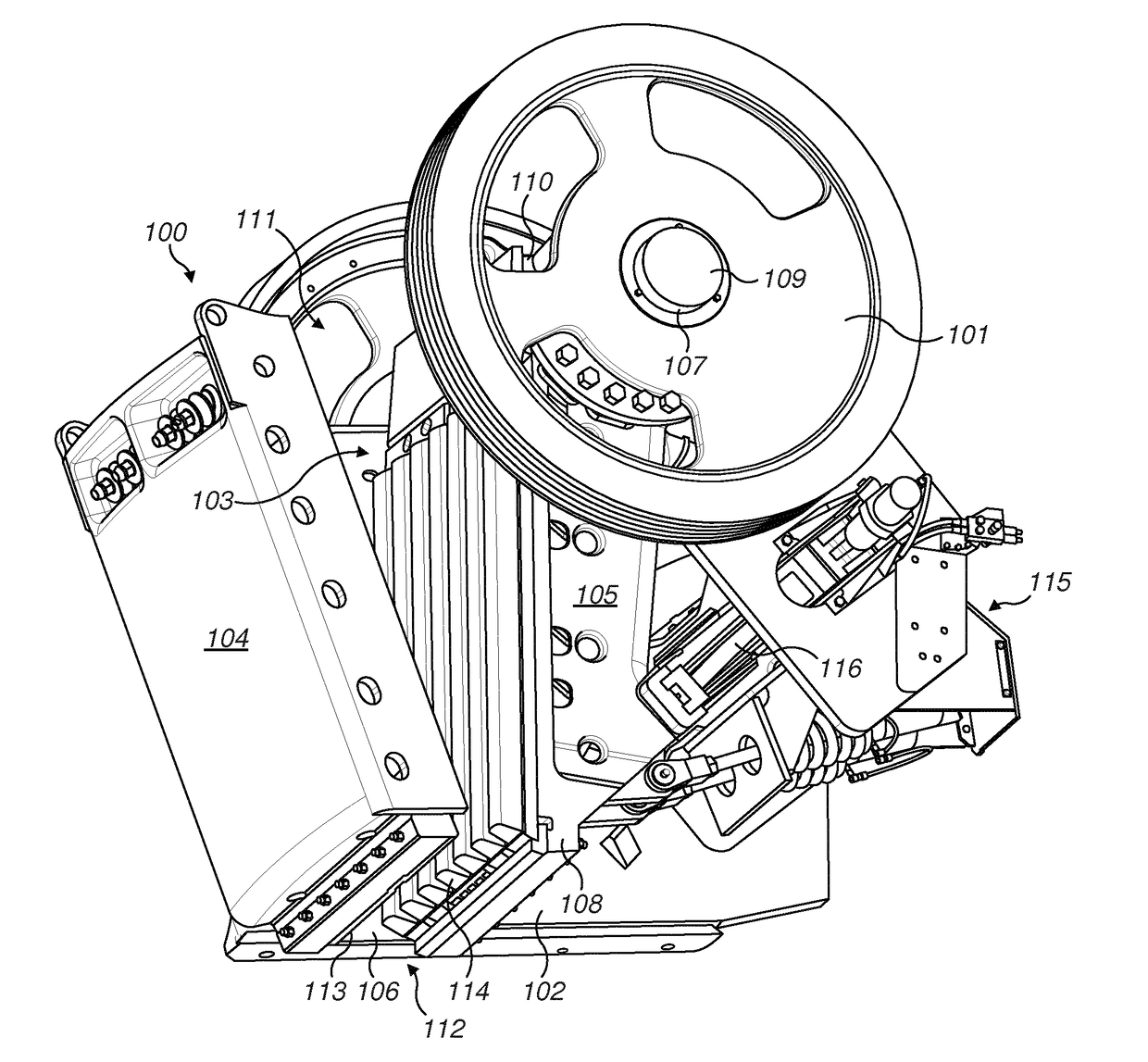

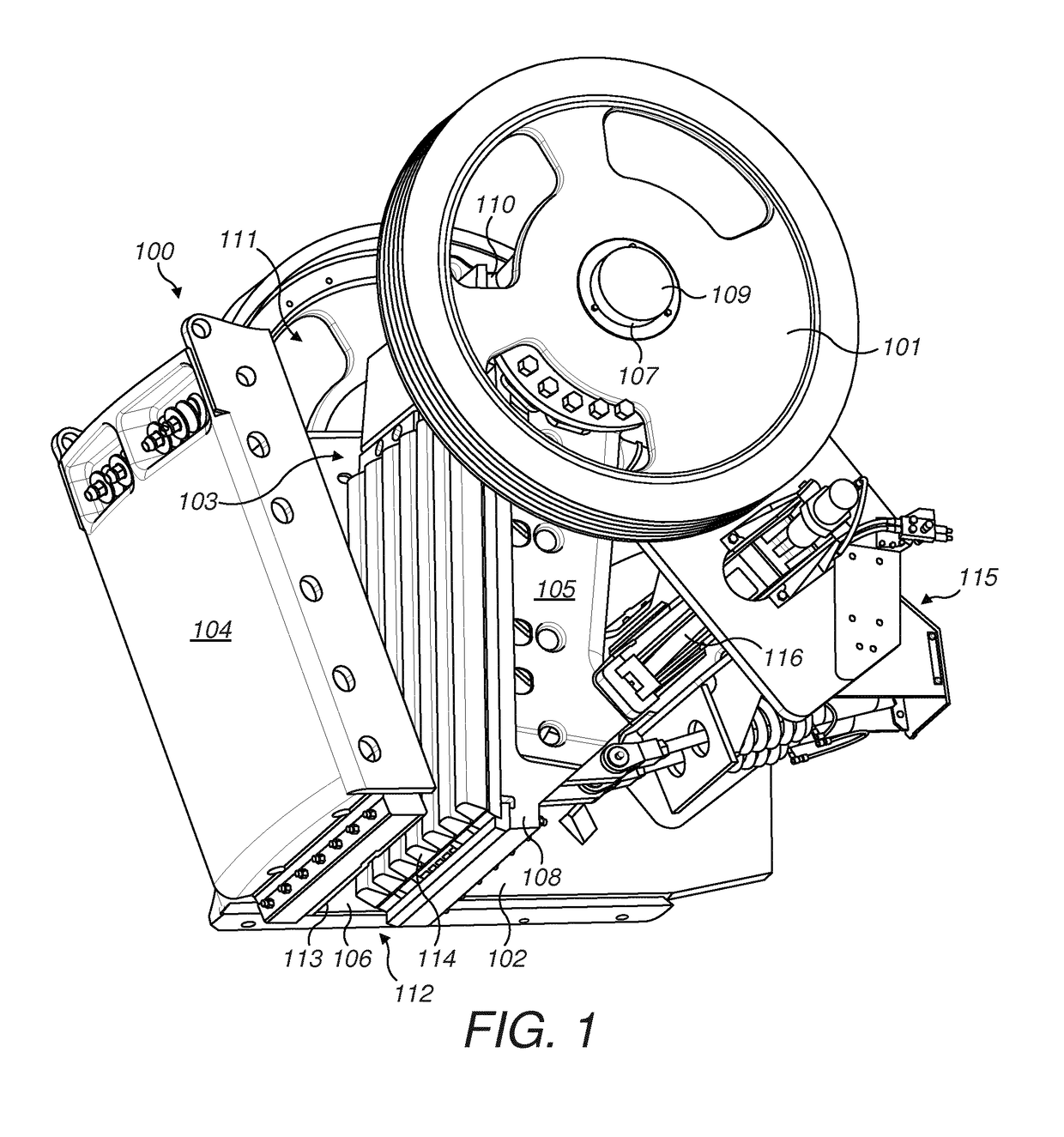

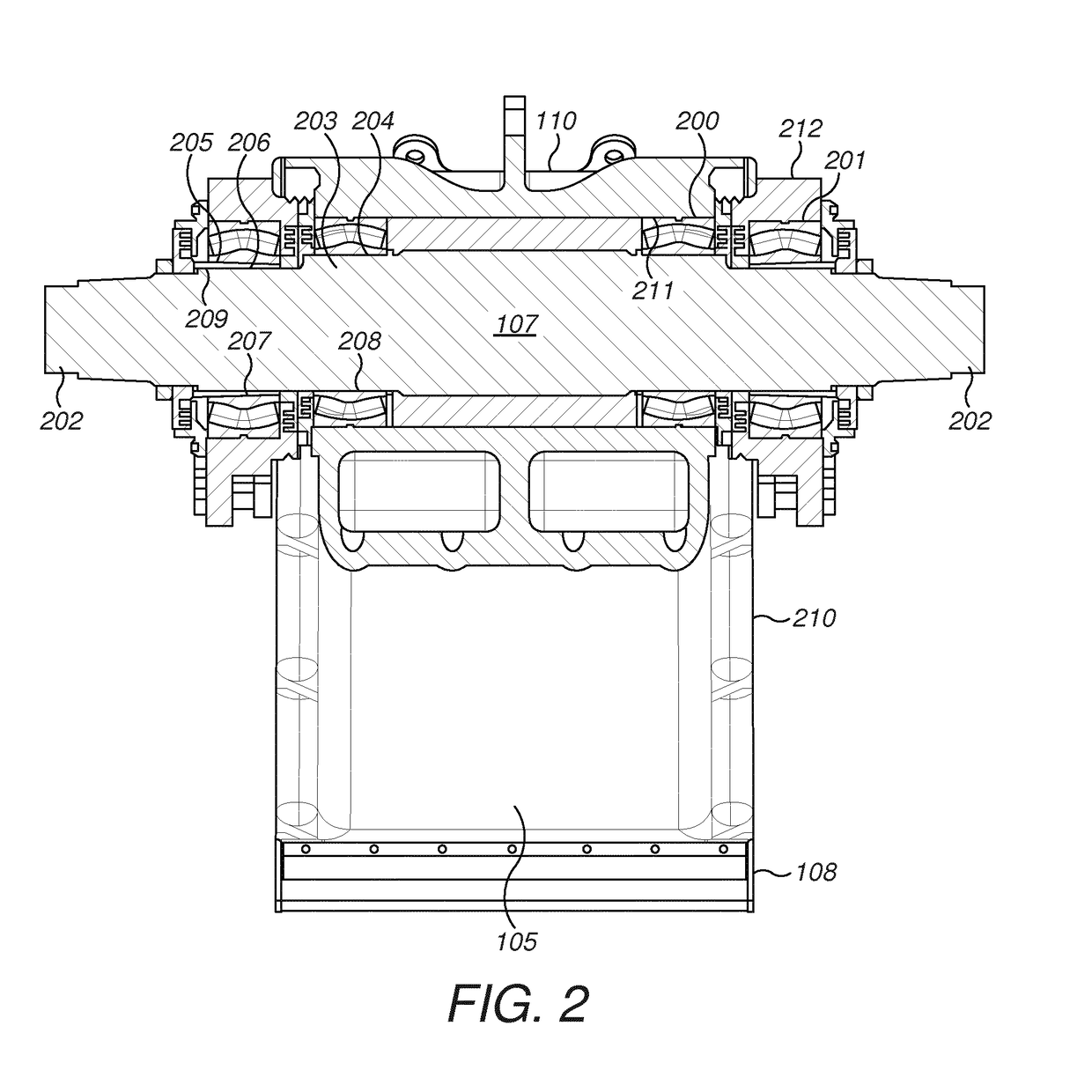

Eccentric crushing jaw mounting assembly

A mounting assembly arranged to mount a jaw at a jaw crusher includes a rotatable shaft having a jaw bearing mount region that is eccentric relative to a longitudinal axis of the shaft. A central axis of a jaw bearing that mounts the jaw at the crusher is off-set from a central axis of a frame bearing that mounts the shaft at the crusher by a distance in the range of 20 mm to 35 mm.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Electrothermal heater mat

ActiveUS10252806B2Lower resistanceEasily maskedDe-icing equipmentsOhmic-resistance heatingIce protection systemGround plane

Owner:GKN AEROSPACE SERVICES LTD

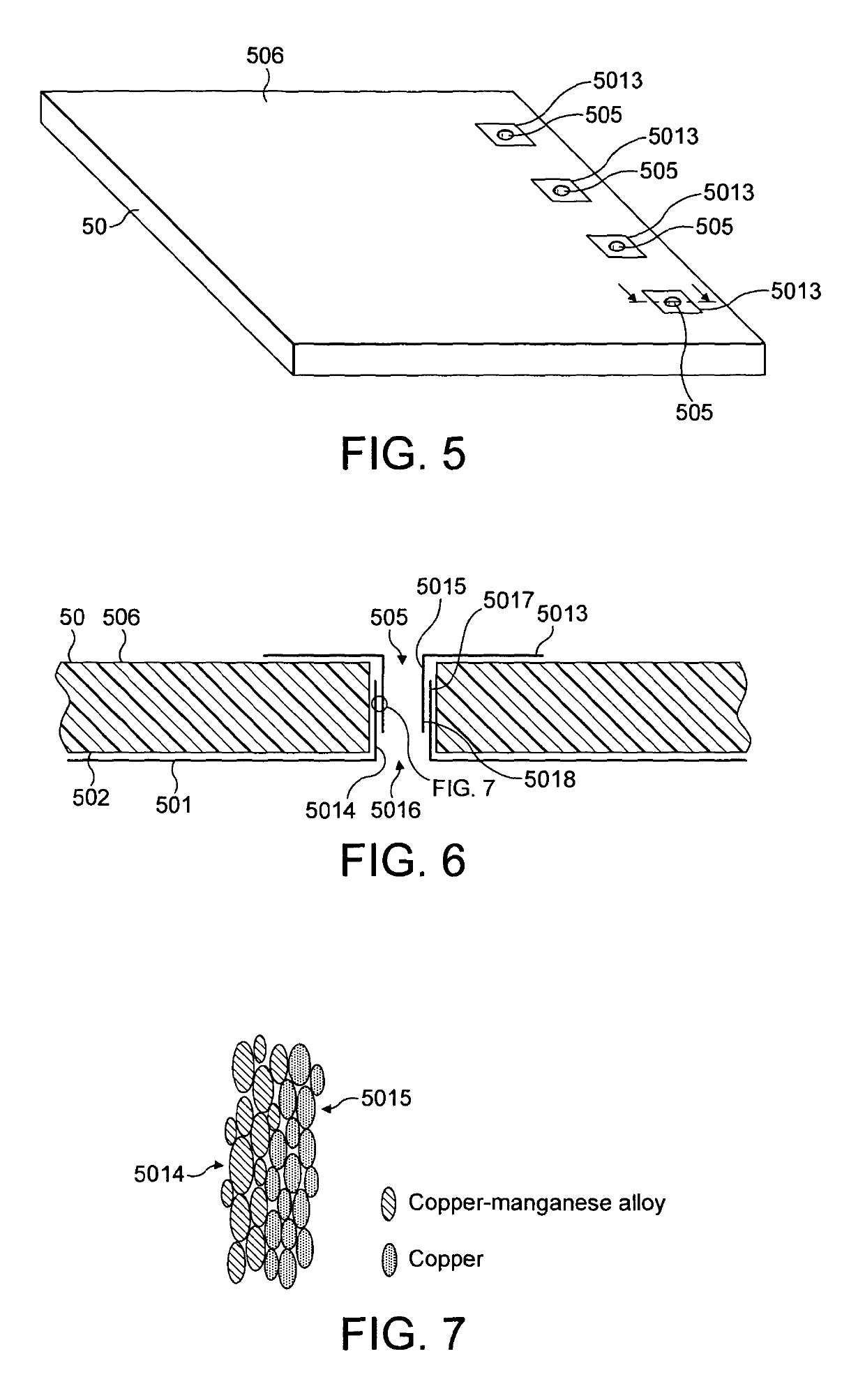

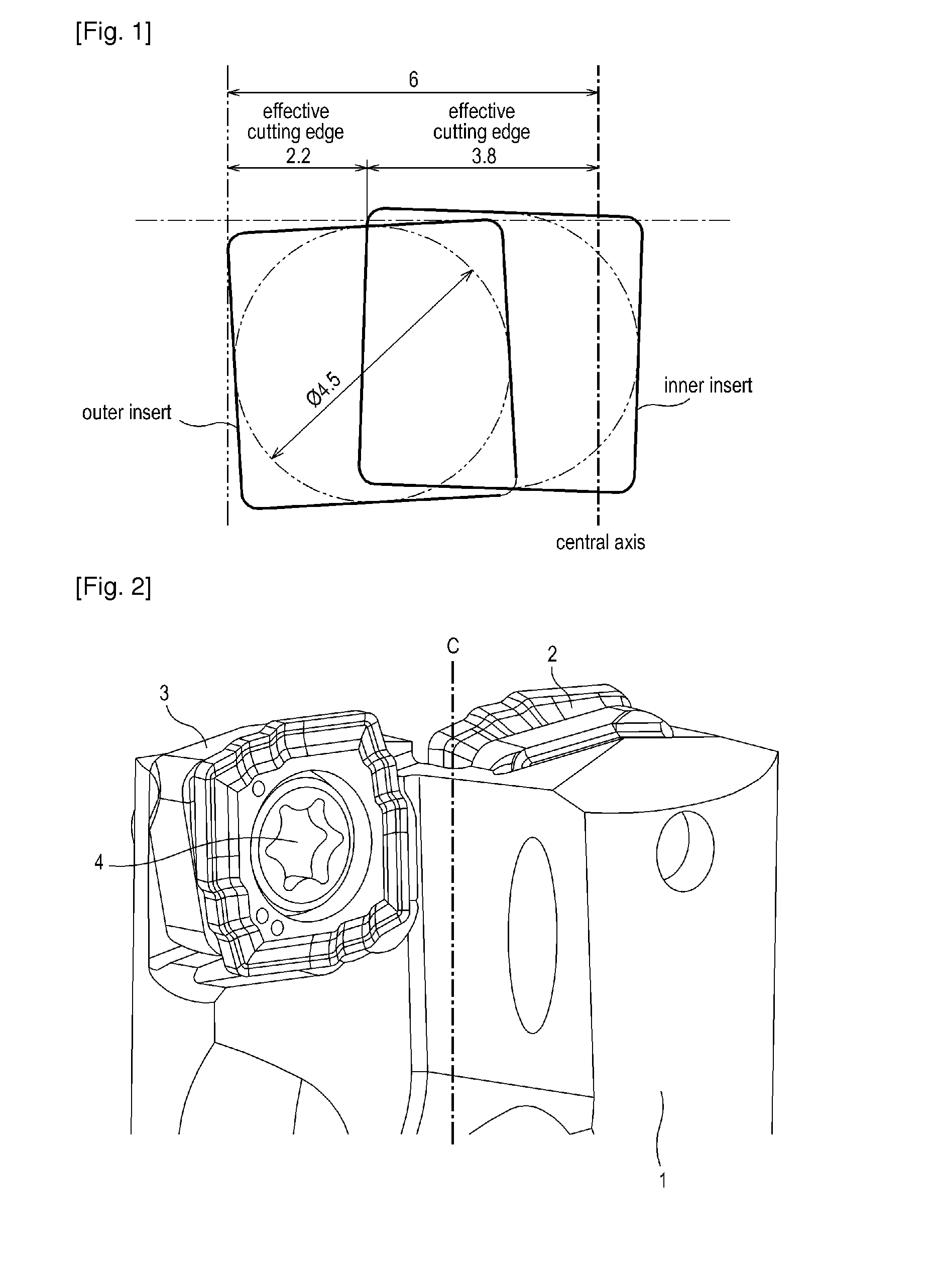

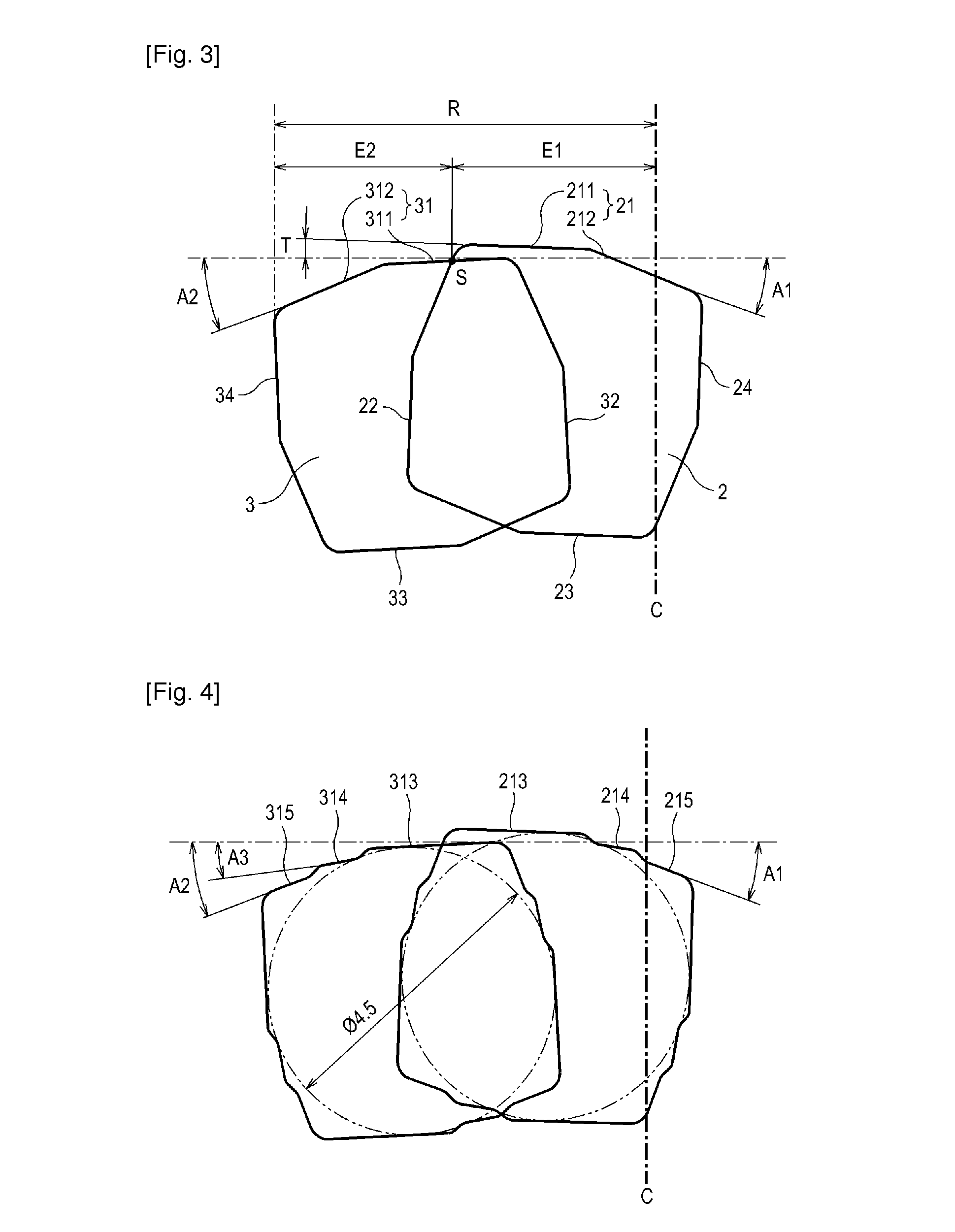

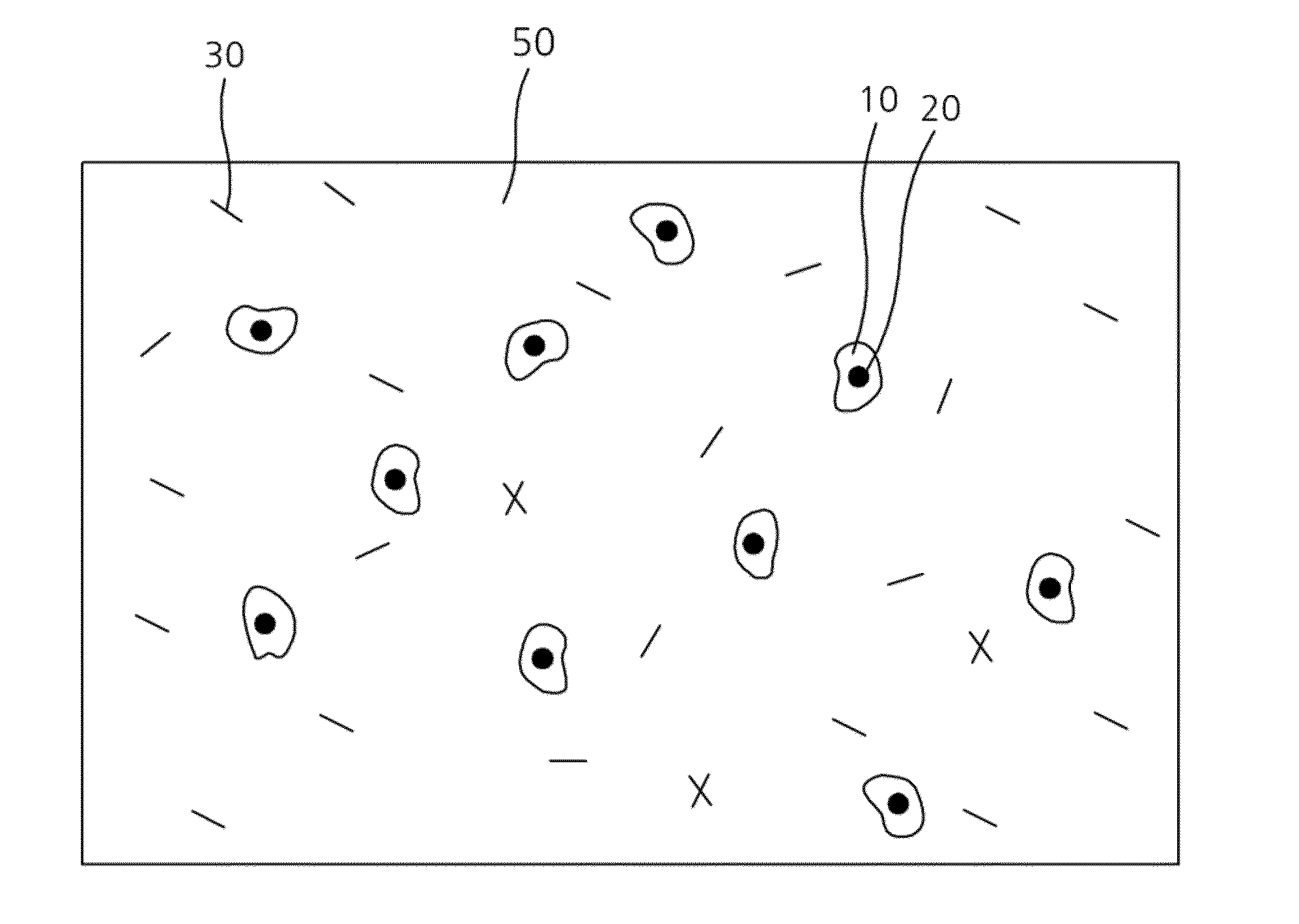

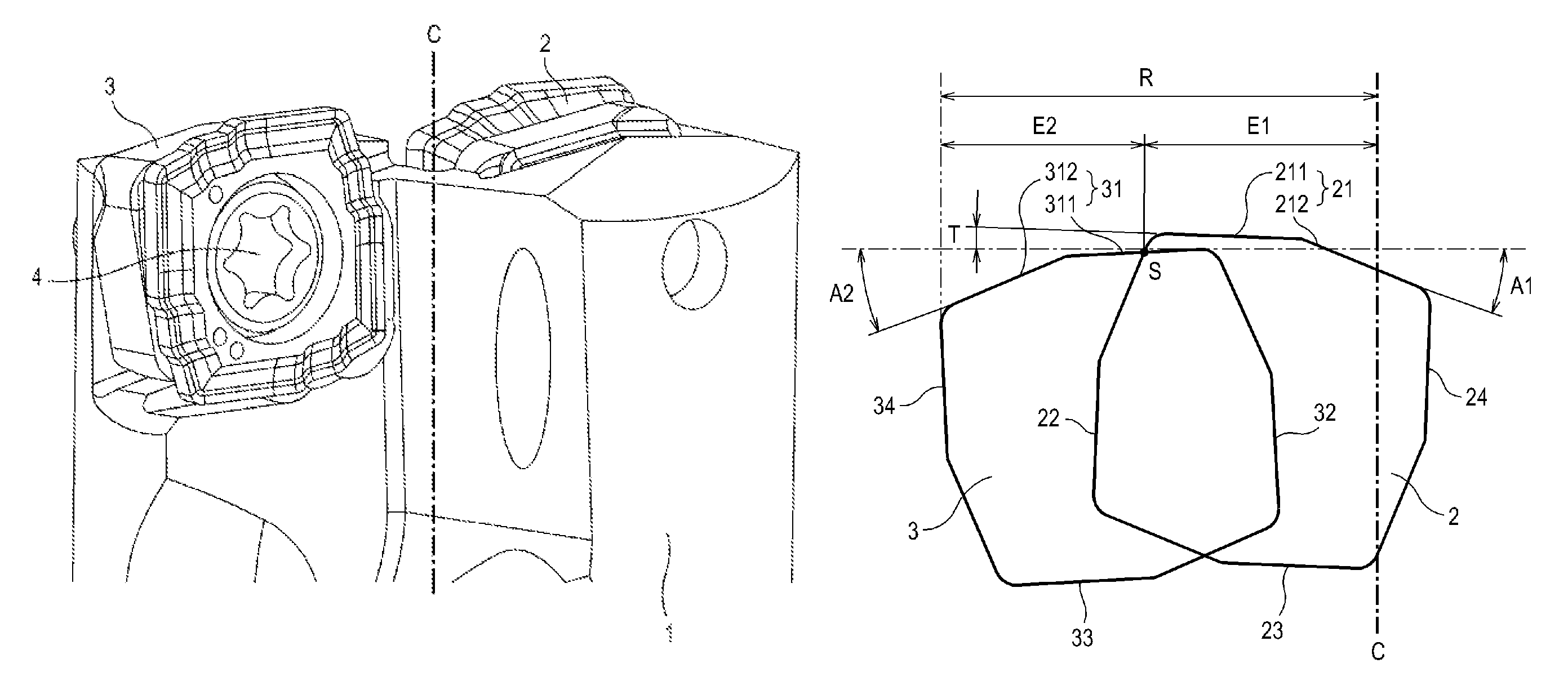

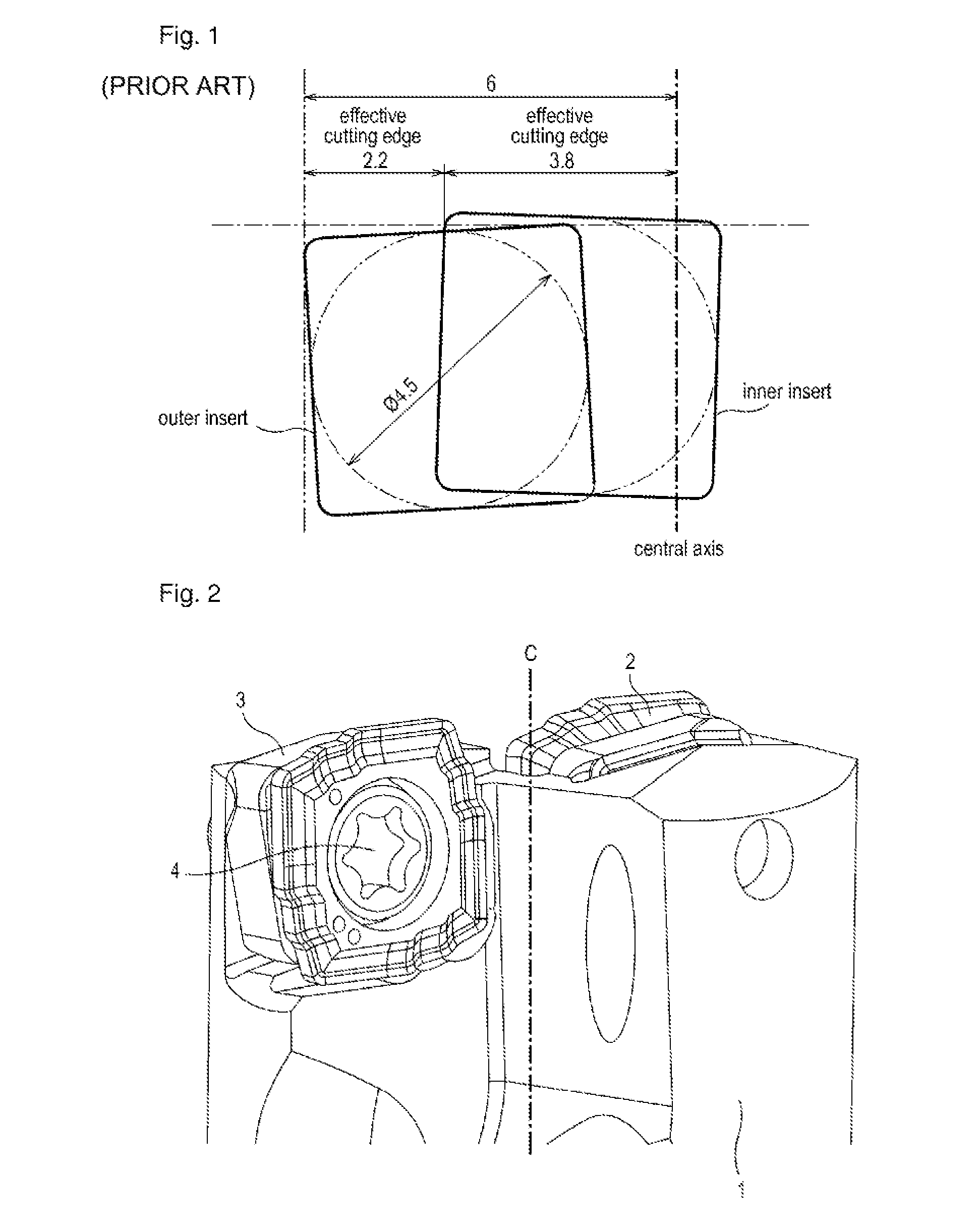

Drill tool

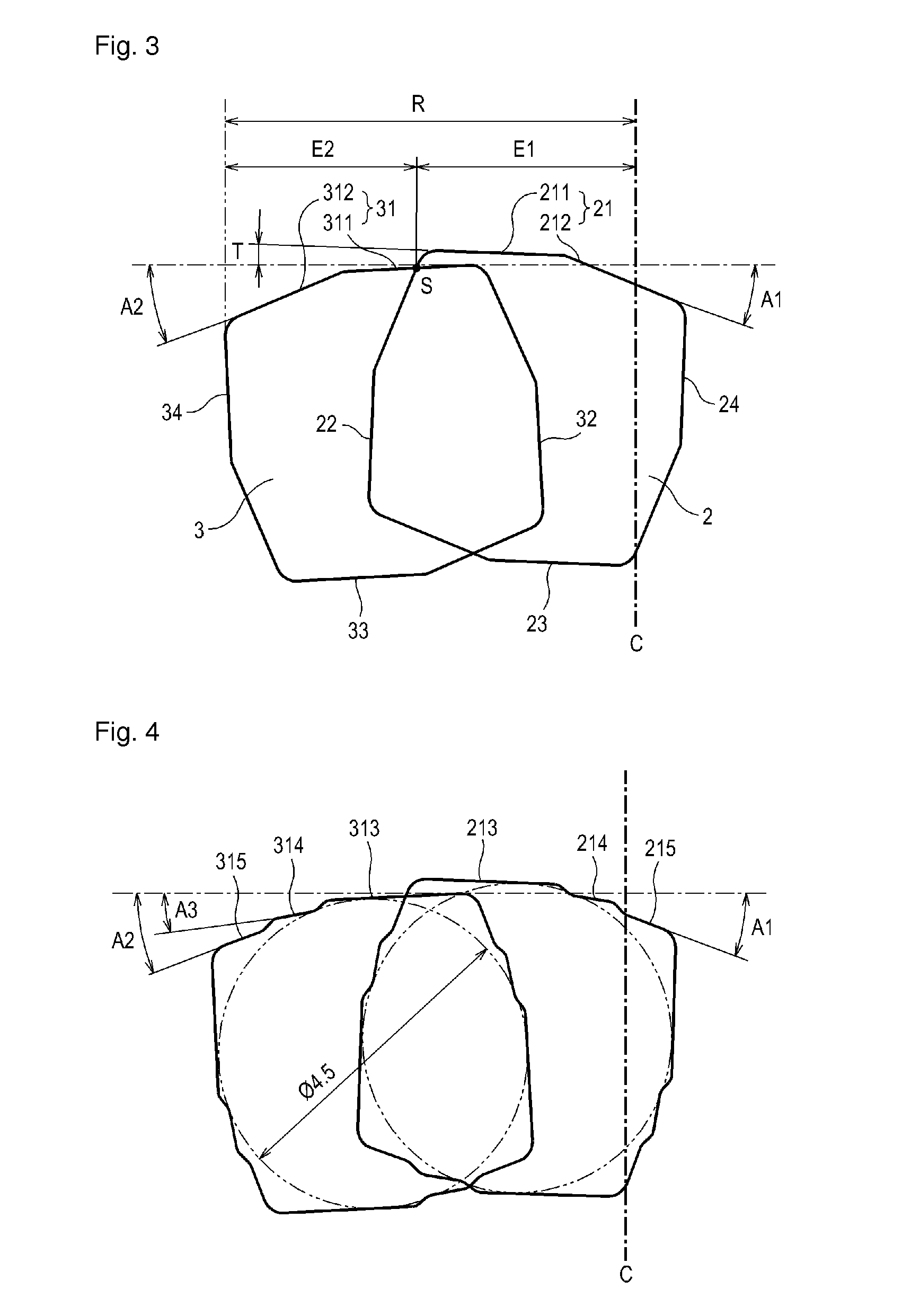

ActiveUS20140133931A1Outstanding strengthOutstanding durabilityWood turning toolsTransportation and packagingEngineeringDrill

A drill tool including a drill body having an inner insert and an outer insert at an end portion of the drill body. The distance from a central axis of the drill body to the outer insert is greater than the distance from the central axis to the inner insert. The cutting edges of the inner and outer inserts can be chamfered with the inner insert chambered at a radially inward portion and the outer insert chamfered at a radially outward portion. The inner insert and the outer insert can be mirror symmetric to one another. The inner insert and the outer insert are mounted to the drill body such that an effective cutting length of the inner insert equals an effective cutting length of the outer insert, the effective cutting lengths being measured in a direction perpendicular to the central axis.

Owner:TAEGUTEC

Titanium alloy with strength greater than 1400MPa

The invention belongs to the field of metal material technology, and relates to a titanium alloy with strength greater than 1400MPa. The titanium alloy provided by the invention consists of the following components by weight percentage: 9%-15% of molybdenum, 4%-8% of iron, 1%-5% of aluminum, no more than 0.08% of carbon, no more than 0.05% of nitrogen, no more than 0.015% of hydrogen, no more than 0.15% of oxygen and the balance of titanium. The titanium alloy of the invention has outstanding strength performance, tensile strength more than 1400 MPa, and good coupling of the strength-plasticity-toughness. The titanium alloy is not easy to crack during the forging process, easy for forming and low in processing cost, can be used as a key bearing component in aviation, also can be widely popularized and used in the fields of aerospace, weapons and other civilian usage, and has significant economic benefits.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Composite and Molded Product Thereof

InactiveUS20140361223A1Outstanding conductivityOutstanding mechanical strengthShielding materialsOther chemical processesPolymer scienceOrganic chemistry

A composite of the present invention comprises: about 10 wt % to about 84 wt % of (A) a thermoplastic resin; about 5 wt % to about 35 wt % of (B) a first filler; about 1 wt % to about 20 wt % of (C) a second filler; and about 10 wt % to about 60 wt % of (D) a third filler, wherein the third filler (D) is a conductive filler, and the melting points of the thermoplastic resin (A), the first filler (B) and the second filler (C) satisfy the following relation 1:Tma−30° C.>Tmb,Tma+500° C.<Tmc [Relation 1](wherein, Tma is the melting point (° C.) of the (A) thermoplastic resin, Tmb is the melting point (° C.) of the (B) first filler, and Tmc is the melting point (° C.) of the (C) second filler).

Owner:CHEIL IND INC

Fuel cell separator precursor, and fuel cell separator

ActiveUS20200365914A1Outstanding strengthEasy transferFinal product manufactureFuel cellsFuel cellsPhysical chemistry

Provided is a fuel cell separator precursor that is obtained by impregnating a porous sheet, which contains a conductive filler, with a resin composition that contains a thermoplastic resin and a conductive filler.

Owner:HISSHINBO HOLDINGS INC

Pearlitic steel rail with high strength and toughness and producing method thereof

InactiveUS20160060736A1High strengthImprove toughnessFurnace typesHeat treatment furnacesChemical compositionHigh intensity

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

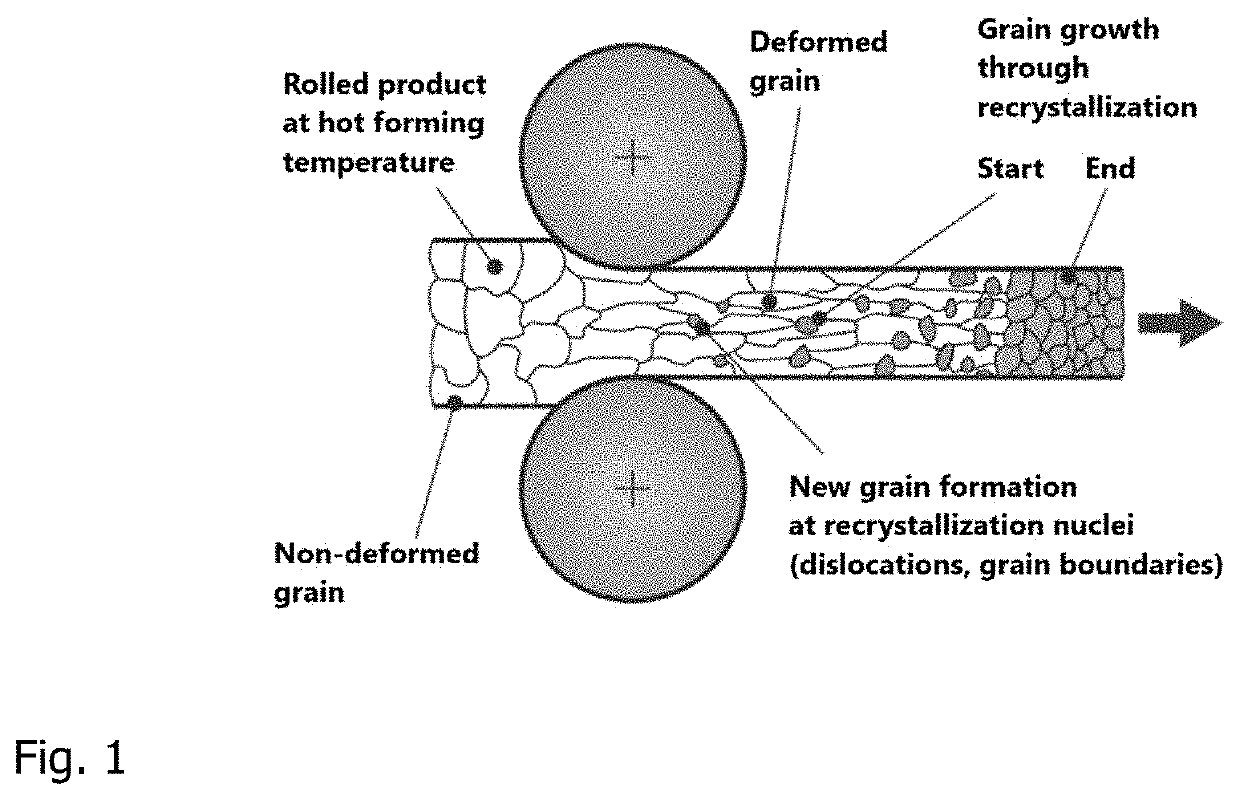

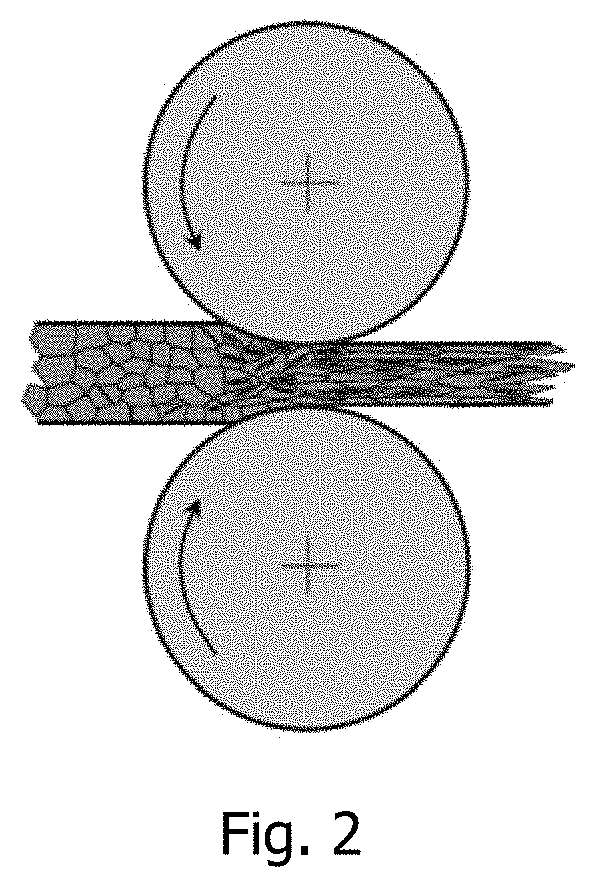

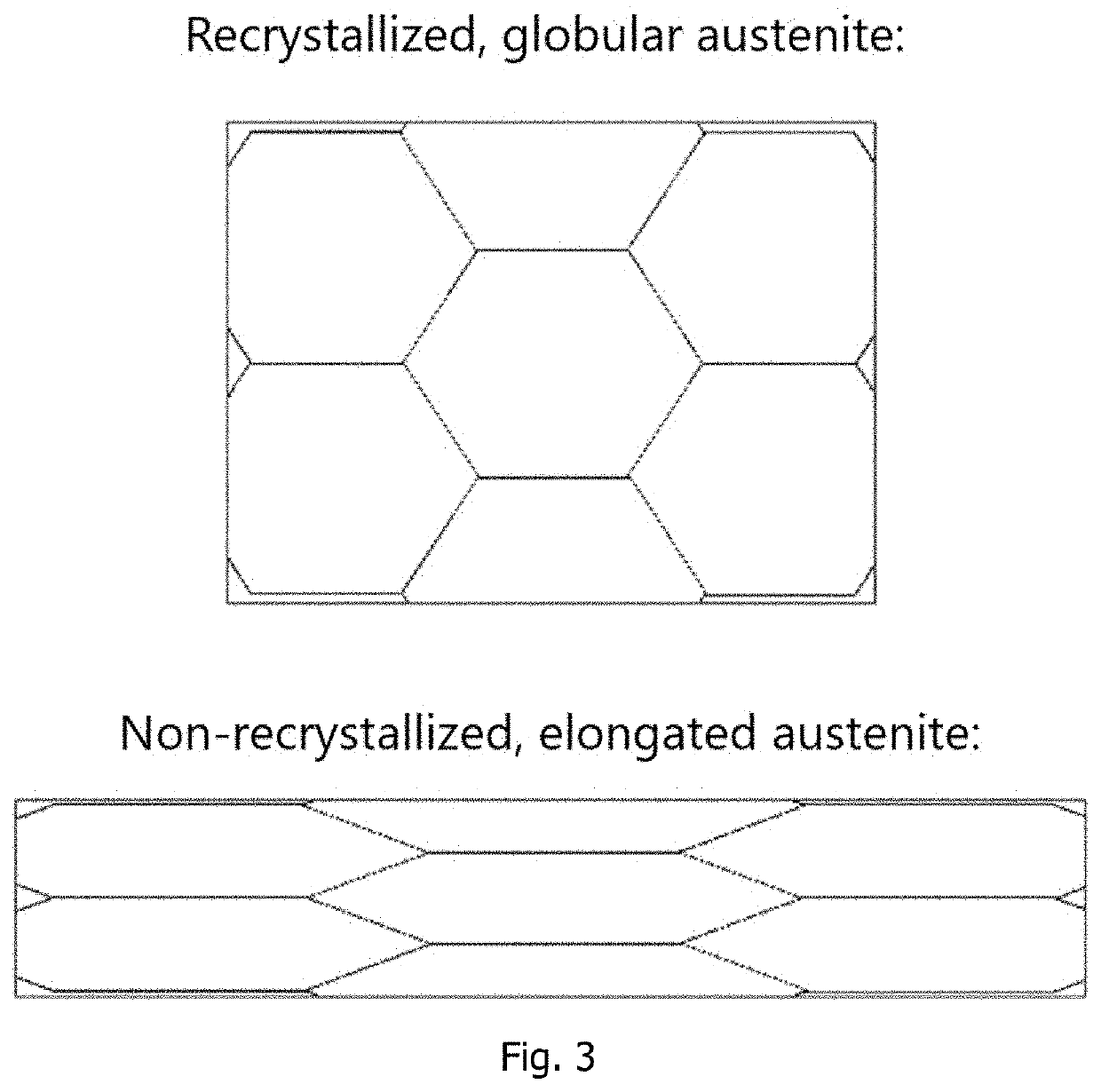

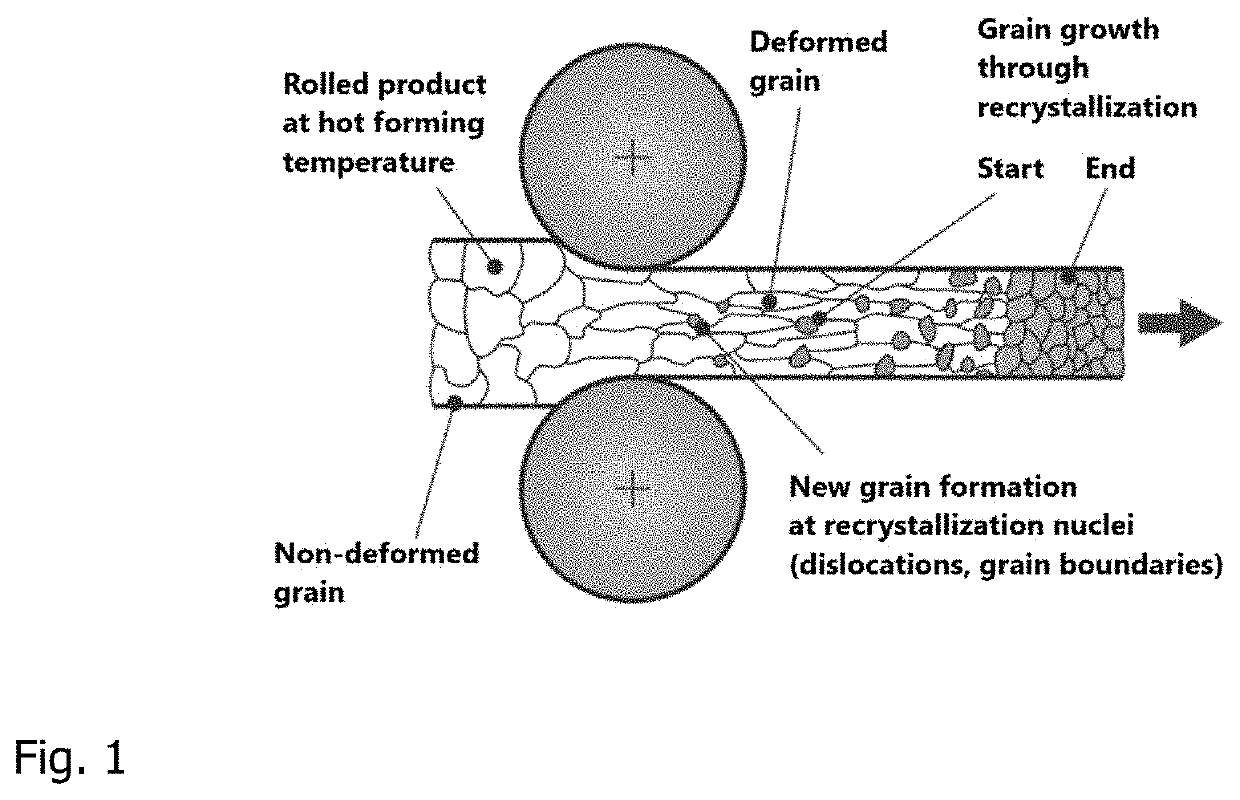

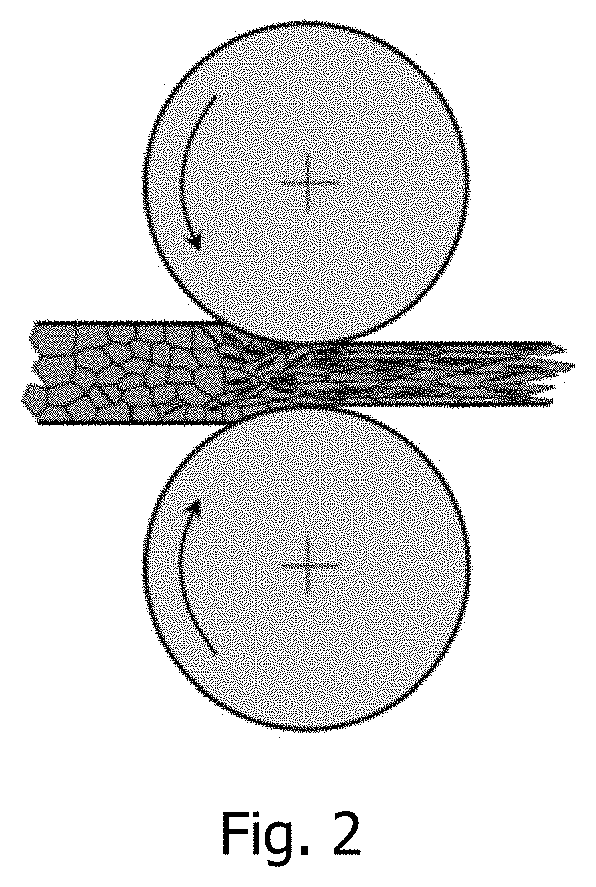

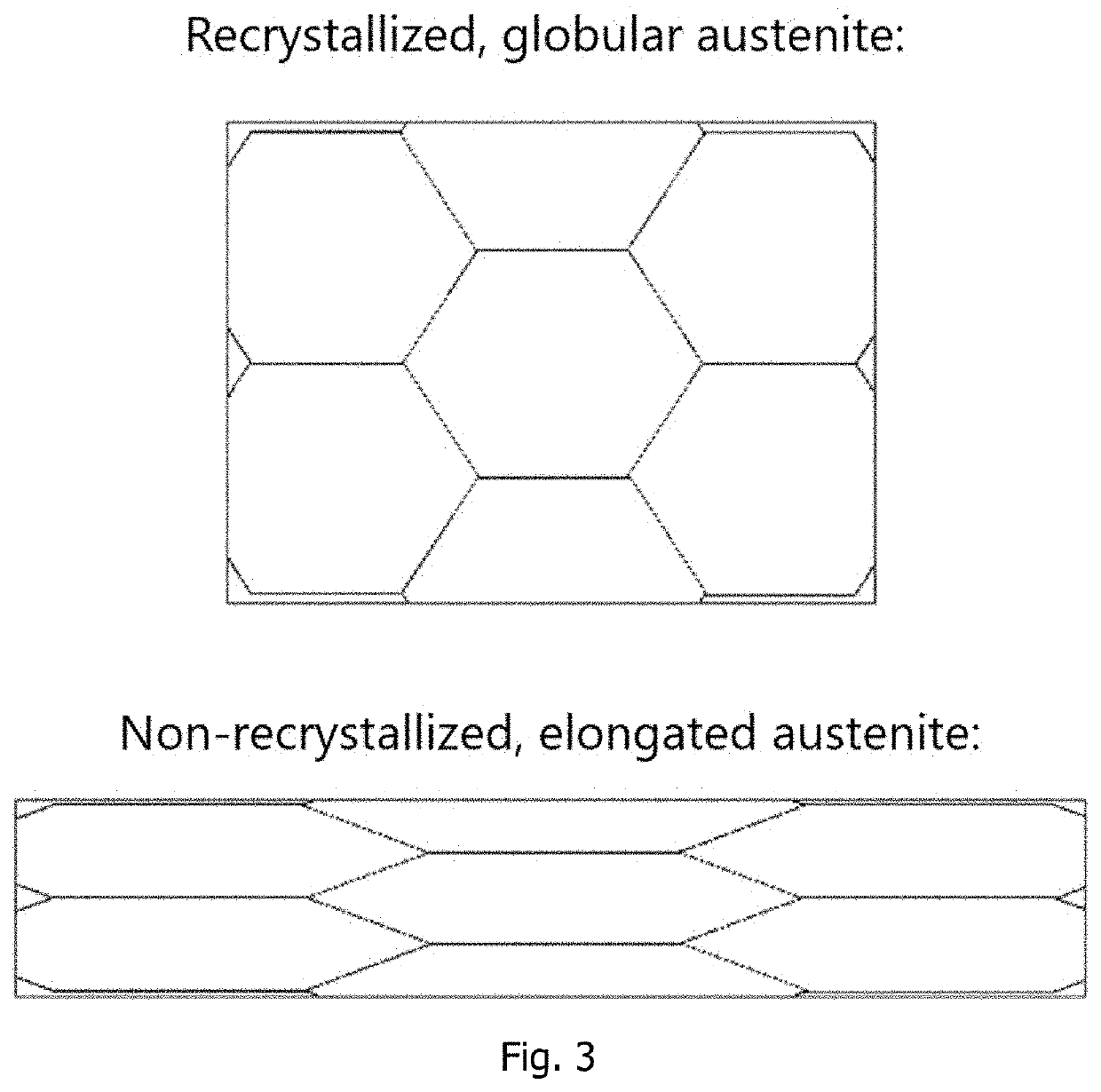

Method for Producing Conventionally Hot-Rolled Profiled Strip Products

PendingUS20220145414A1Improve propertiesEasy to processFurnace typesIncreasing energy efficiencyIngotMechanical property

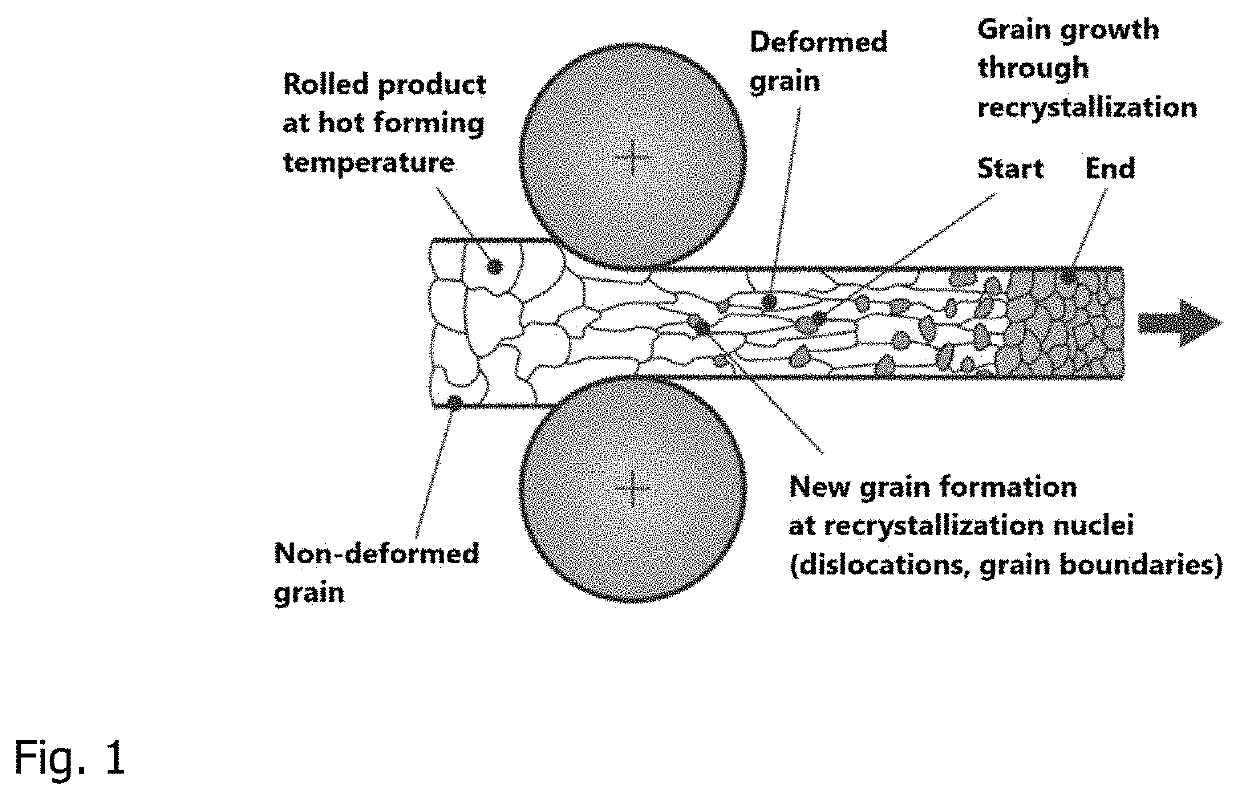

The invention relates to a method for producing hot-rolled hot strip products in which a steel alloy is melted; the melted steel alloy is cast into slab ingots and after being heated to a temperature above Ac3, the slab ingots are hot rolled until they reach a desired degree of deformation and a desired strip thickness; the rolling is performed above the recrystallization temperature of the alloy; after the rolling, the strip is cooled to room temperature and for hardening purposes, is briefly heated to a temperature >Ac3 and cooled again, characterized in that the heating takes place with a temperature increase of more than 5 K / s, more than 10 K / s, more than 50 K / s, or more than 100 K / s and is kept at a desired target temperature for a period of 0.5 to 60 s before cooling to yield improved mechanical properties. and then a cooling takes place;

Owner:VOESTALPINE STAHL GMBH

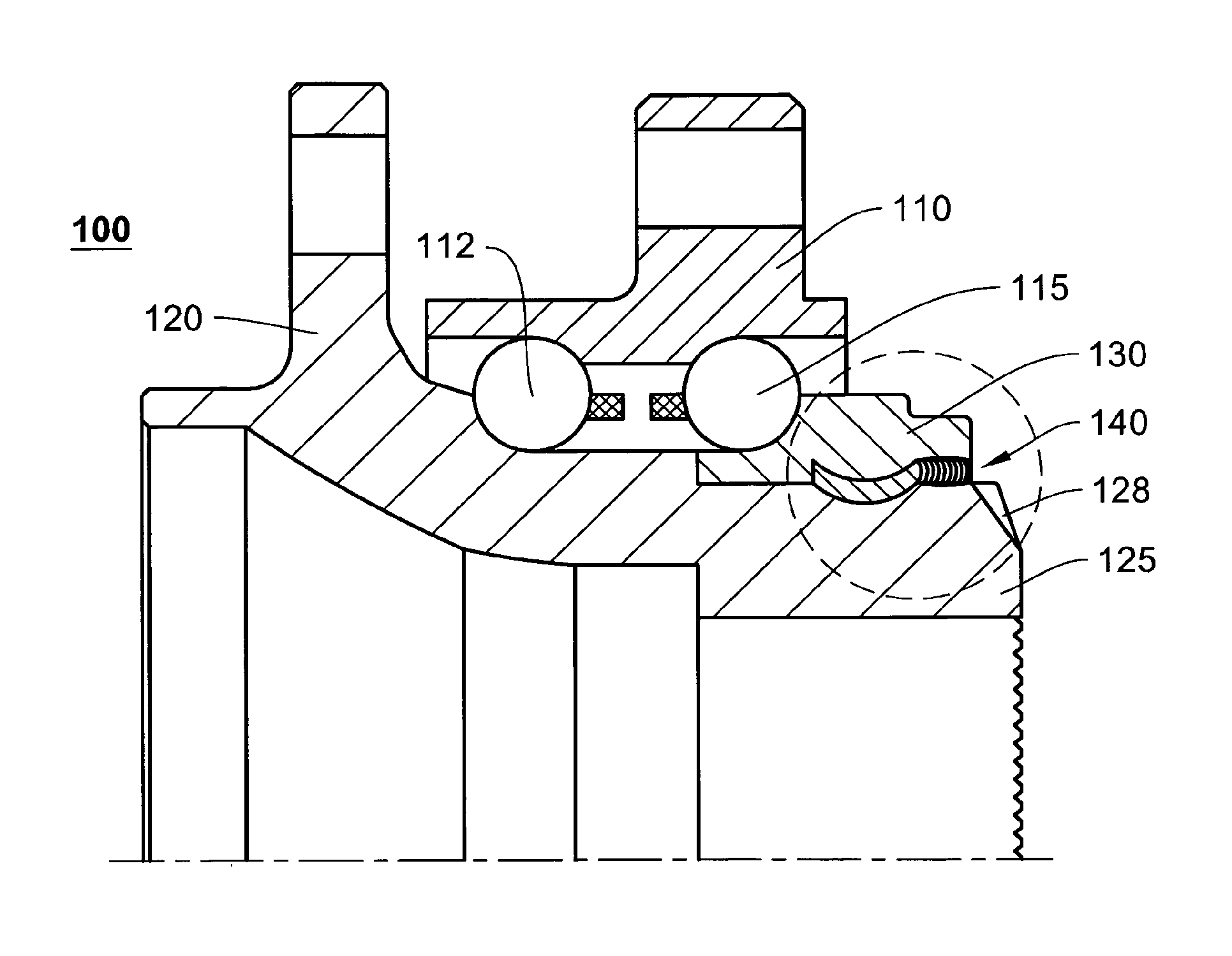

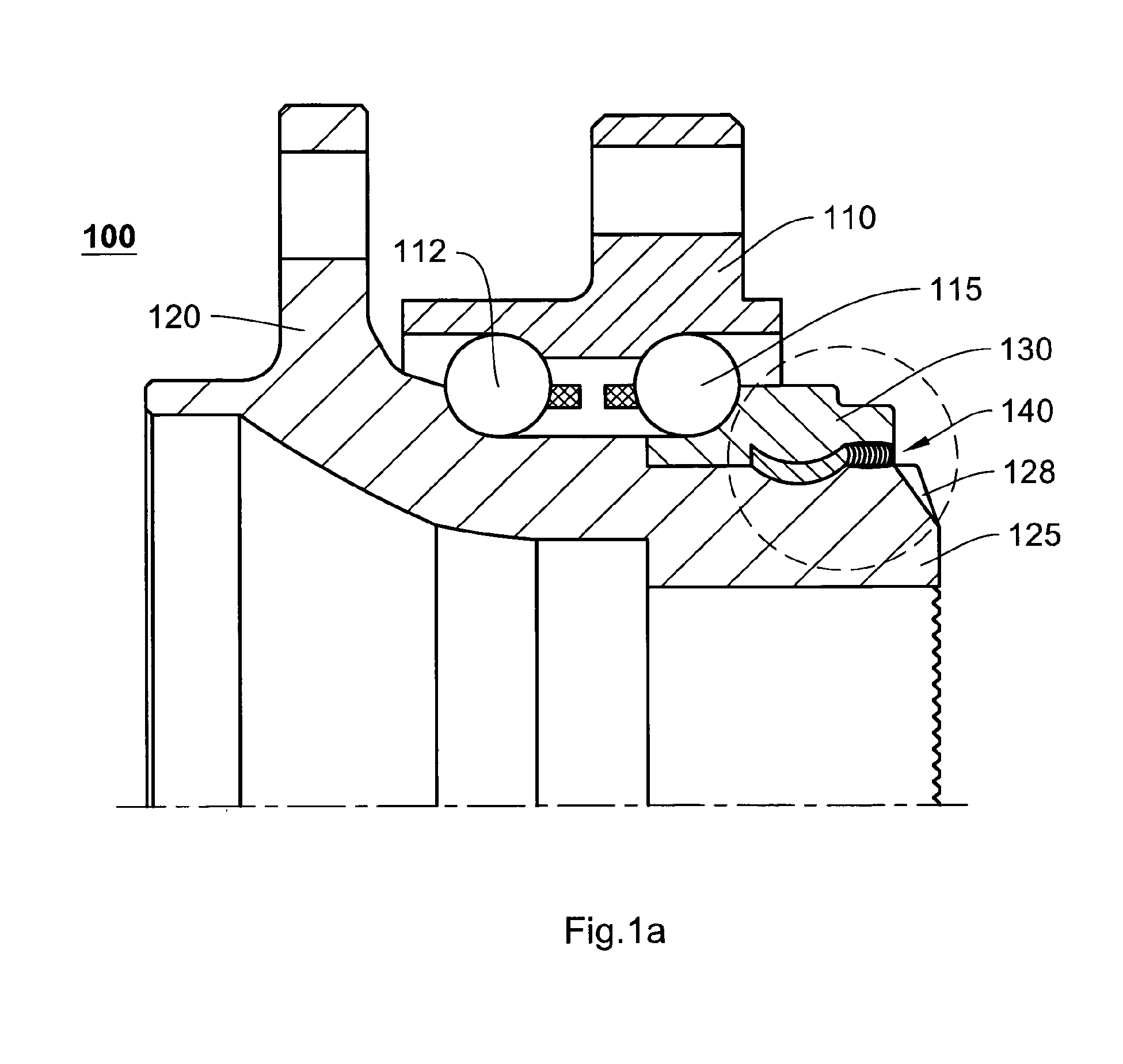

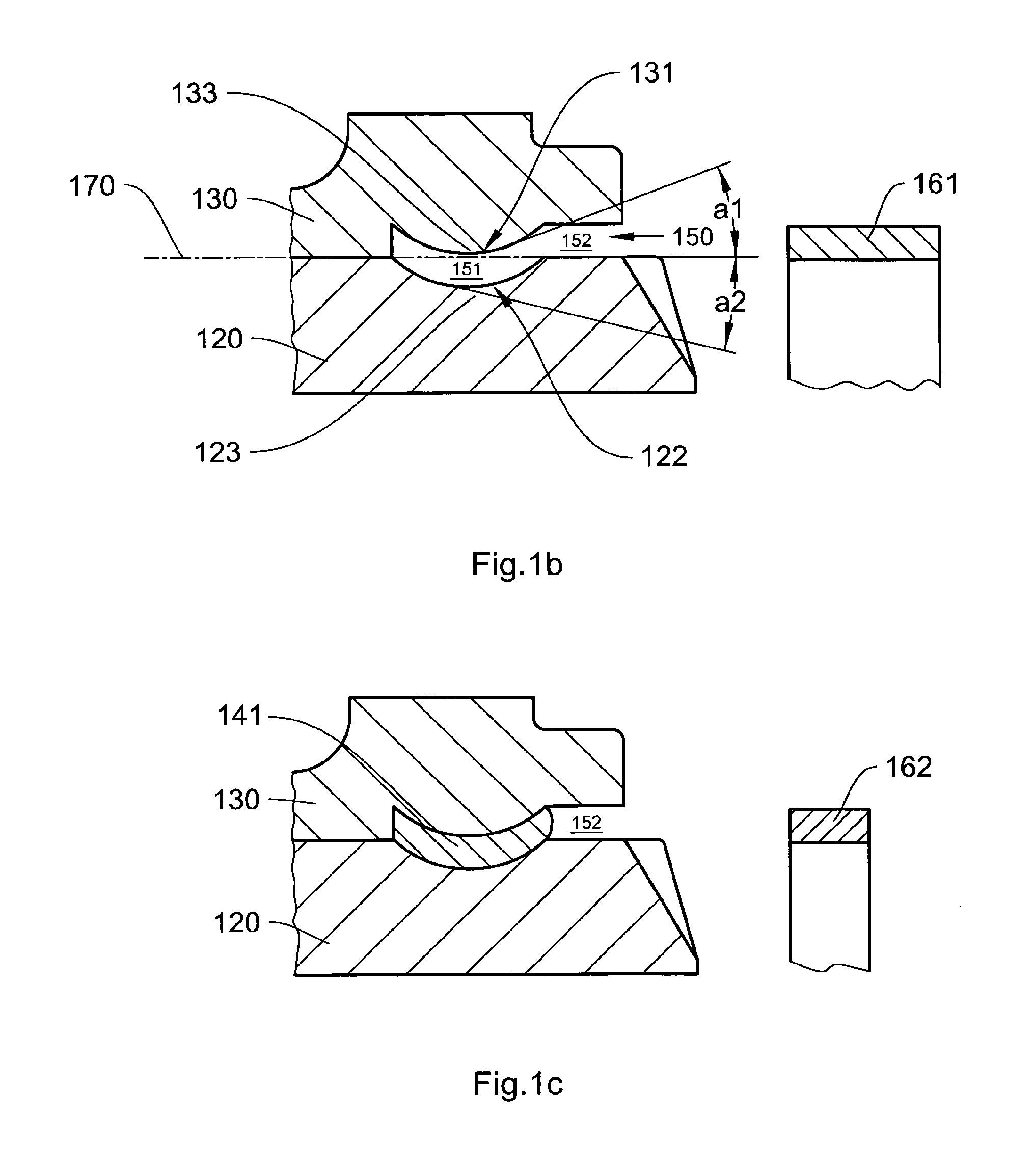

Assembly comprising a radially intermediate joint

InactiveUS20140193191A1High strengthExcellent shear strengthRolling contact bearingsBearing assemblyBiomedical engineeringMetallic materials

The present invention resides in an assembly comprising a first component (130) joined to a second component (120) by means of an intermediate joint. The first component has a first joining surface arranged coaxially and in spaced juxtaposition around a second joining surface of the second component, such that a radial gap is defined between the first and second joining surfaces. Furthermore, at least one of the first and second joining surfaces comprises a circumferential groove. The intermediate joint is formed by metal material that substantially fills the radial gap, whereby a first portion (141) of the intermediate joint comprises metal material that has been plastically deformed to fill the circumferential groove. According to the invention, the intermediate joint comprises a second portion (142), formed by metal material that has been welded or brazed to the first joining surface and to the second joining surface.

Owner:SKF BV

Zirconia sintered body having high linear light transmittance

PendingUS20220153649A1Outstanding strengthConveniently producedTooth crownsArtificial teethFluorescenceTransmittance

A zirconia sintered body may excel in translucency, strength, and linear light transmittance with no use of an HIP device, and a zirconia molded body and a zirconia pre-sintered body from which such a zirconia sintered body can be obtained. A zirconia molded body may include zirconia particles with 2.0 to 9.0 mol % yttria, an average primary particle diameter of 60 nm or less, and 0.5 mass % or less zirconia particles having a particle diameter >100 nm, wherein the zirconia molded body has ΔL*(W−B) of 5+ through a thickness of 1.5 mm. A zirconia pre-sintered body may include 2.0 to 9.0 mol % yttria, and have a ΔL*(W−B) of 5+ through a thickness of 1.5 mm. A zirconia sintered body may include: a fluorescent agent; 2.0 to 9.0 mol % yttria, and have a linear light transmittance of 1% or more through a thickness of 1.0 mm.

Owner:KURARAY NORITAKE DENTAL

Method for Producing Thermo-Mechanically Produced Profiled Hot-Rolled Strip Products

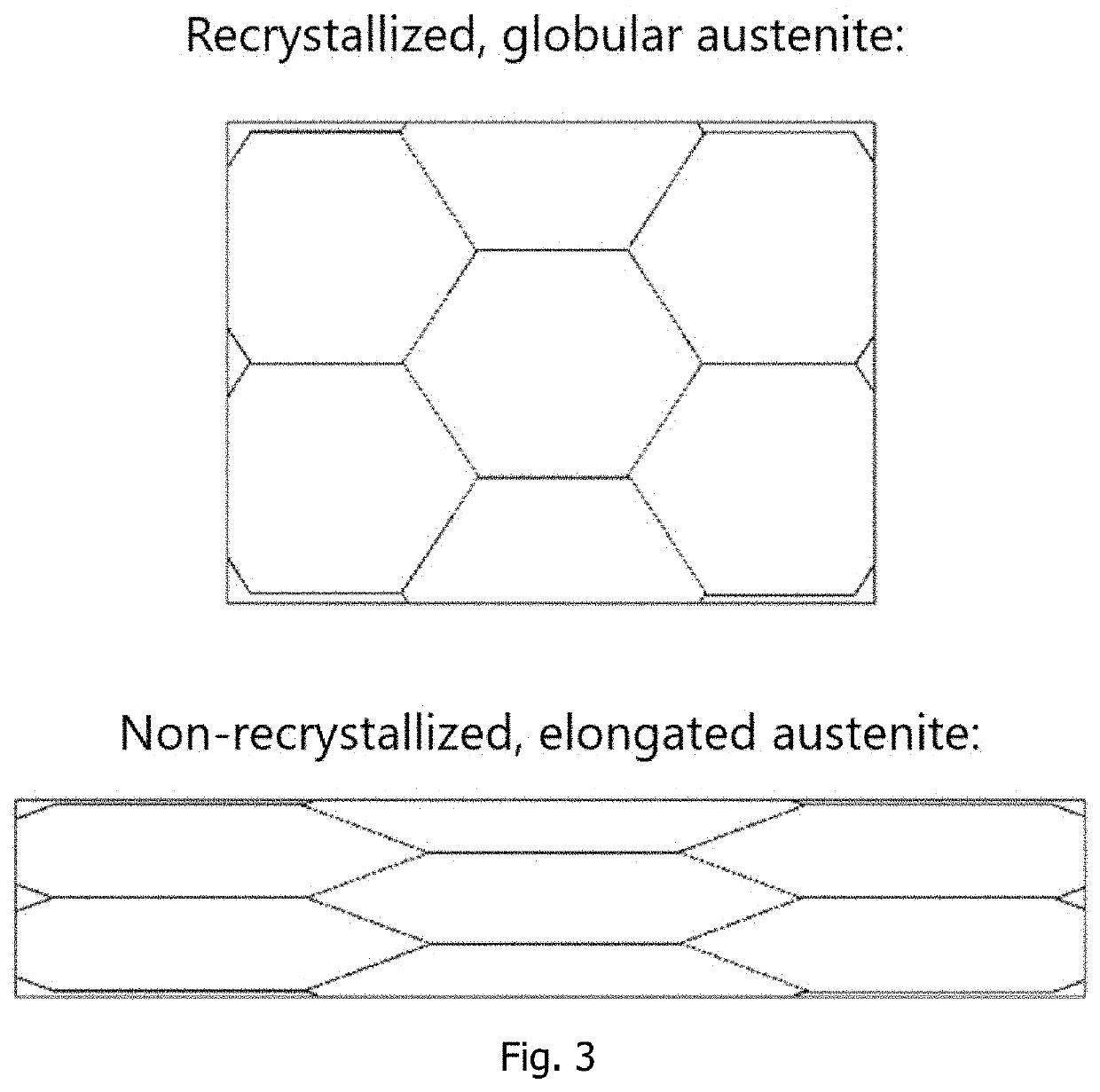

PendingUS20220010404A1Outstanding strengthOutstanding toughnessFurnace typesIncreasing energy efficiencyIngotRe crystallization

A method for producing thermomechanically produced hot strip products in which a steel alloy is melted; the steel alloy is adjusted so that a recrystallization during the hot rolling is suppressed; the final rolling temperature is greater than 800° C.; the melted steel alloy is cast into slab ingots and after being heated to a temperature above Ac3, the slab ingots are hot rolled until they reach a desired degree of deformation and a desired strip thickness; after the rolling, the strip is cooled to room temperature and for hardening purposes, is briefly heated to a temperature>Ac3 and cooled again, characterized in that the heating takes place with a temperature increase of more than 5 K / s, more than 10 K / s, with more than 50 K / s, or more than 100 K / s and is kept at a desired target temperature for a period of 0.5 to 60 s before cooling to yield improved mechanical properties. The hot strip products thus produced have a crystal structure that is up to 90% martensite, with the remainder being comprised of austenite and bainite.

Owner:VOESTALPINE STAHL GMBH

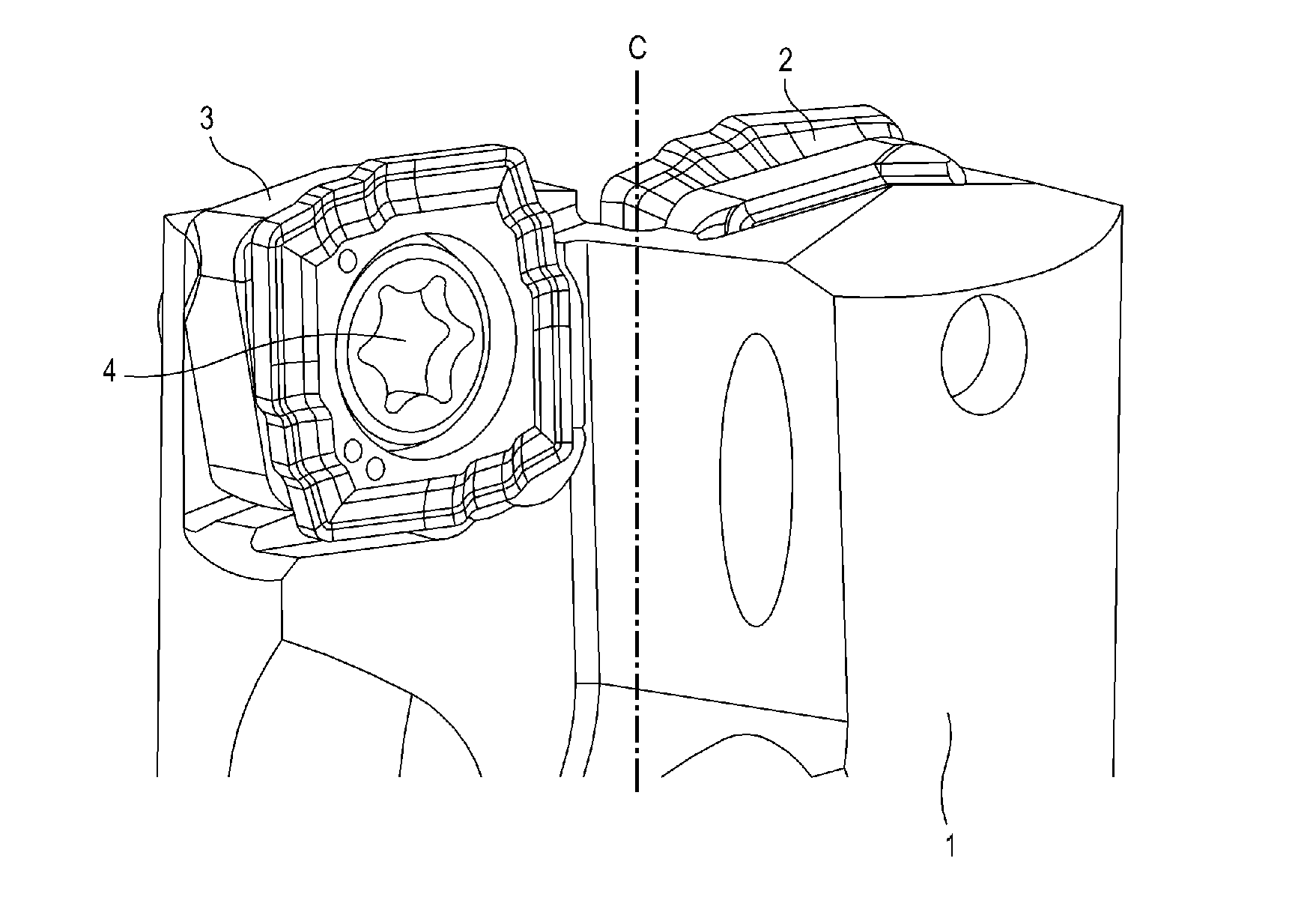

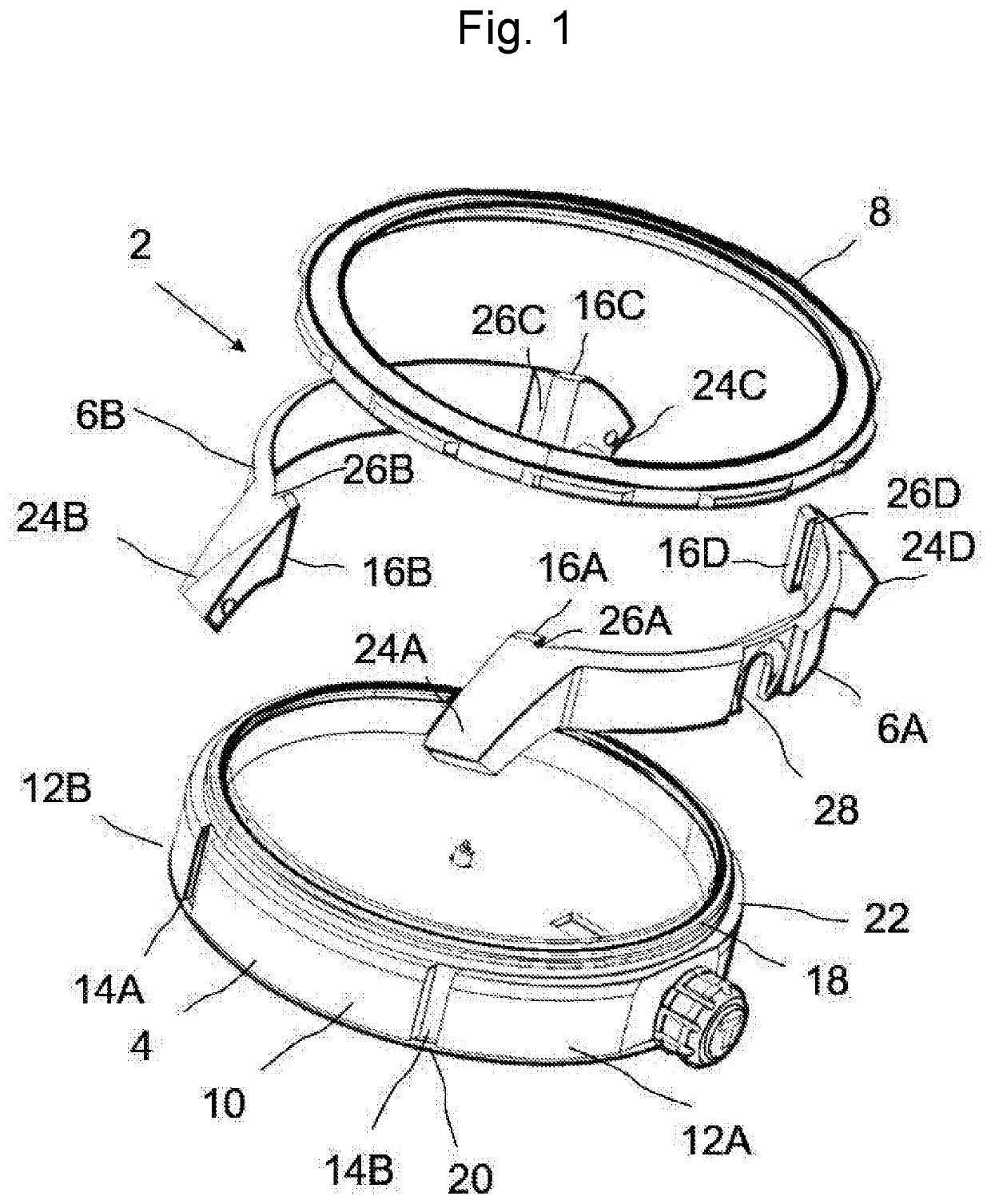

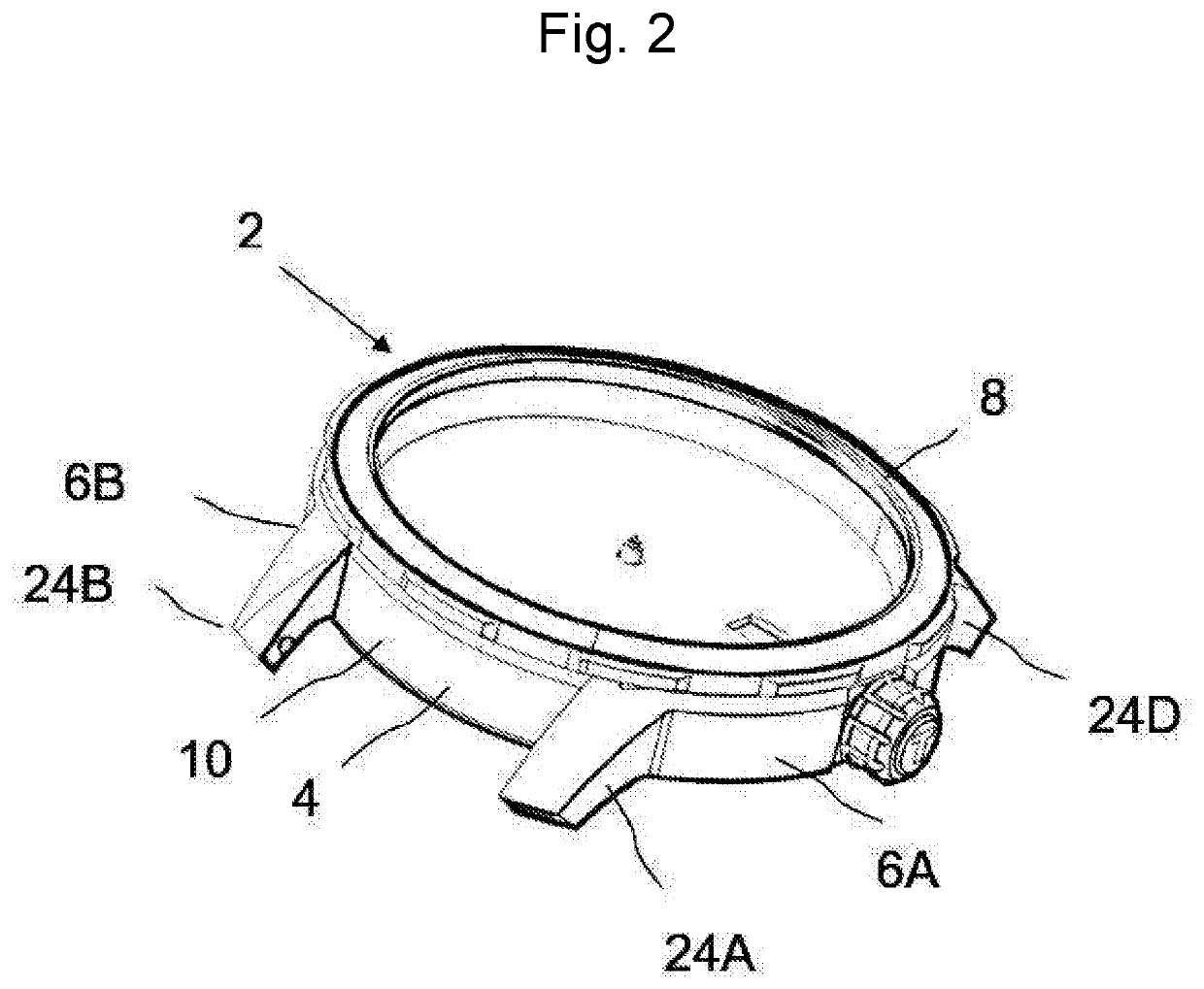

Timepiece with attached horns

ActiveUS20200397100A1Simple stepsOutstanding strengthClockwork casesBraceletsStructural engineeringLower face

A watch case (2) for wristwatches including: a middle part (4) including a side wall (10) having two sides (12A, 12B); two separate side members (6A, 6B) arranged on either side of the middle part (4), each side member (6A, 6B) extending beyond the space occupied by the middle part (4) in the longitudinal direction of the watch band and having a median portion of complementary shape to the corresponding side (12A, 12B) of the middle part (4), each side member (6A, 6B) being slidably and removably attached to the middle part (4); a bezel (8) secured to the middle part (4) on an upper face of the middle part (4); a back cover (20) fixed on a lower face of the middle part (4); characterized in that each side member (6A, 6B) is blocked in translation in the direction of sliding on the middle part (4) by the bezel (8).

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Method for Producing Thermo-Mechanically Produced Hot-Rolled Strip Products

PendingUS20220018008A1Improve propertiesEasy to processIncreasing energy efficiencyFurnace typesIngotMaterials science

The invention relates to a method for producing thermomechanically produced hot strip products in which a steel alloy is melted; the steel alloy is adjusted so that a recrystallization during the hot rolling is suppressed; the final rolling temperature is greater than 800° C.; the melted steel alloy is cast into slab ingots and after being heated to a temperature above Ac3, the slab ingots are hot rolled until they reach a desired degree of deformation and a desired strip thickness; after the rolling, the strip is cooled to room temperature and for hardening purposes, is briefly heated to a temperature >Ac3 and cooled again, characterized in that the heating takes place with a temperature increase of more than 5 K / s, more than 10 K / s, more than 50 K / s, or more than 100 K / s, and is kept at a desired target temperature for a period of 0.5 to 60 s before cooling to yield improved mechanical properties.

Owner:VOESTALPINE STAHL GMBH

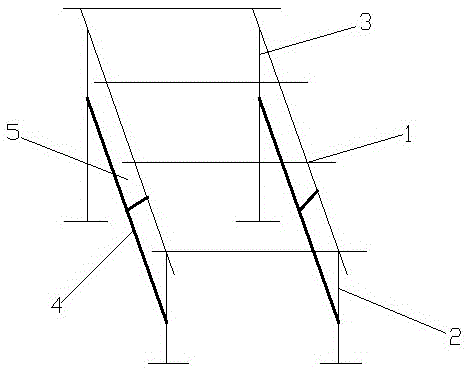

High-strength photovoltaic module bracket

InactiveCN105490623AReasonable structural designEasy to installPhotovoltaic supportsPhotovoltaic energy generationEngineeringUltimate tensile strength

The invention discloses a high-strength photovoltaic module bracket. The bracket comprises a supporting frame, front supporting rods, back supporting rods and related connection fittings, wherein the supporting frame is mounted at the upper parts of the front and back supporting rods and is arranged in an inclined state; reinforced rods are added between the front supporting rods and the back supporting rods; one ends of the reinforced rods are hinged with the front supporting rods while the other ends of the reinforced rods are connected with the back supporting rods by bolts; the reinforced rods are fixedly connected with the supporting frame by adopting connecting rods; and the connecting rods are connected with the reinforced rods and the supporting frame by bolts. The invention discloses the high-strength photovoltaic module bracket; the bracket is reasonable in structural design, convenient to mount, moderate in preparation cost, and particularly excellent in strength performance; the stress transfer between the front supporting rods an the back supporting rods is realized through the structure of added reinforced rods and the connecting rods, so that the supporting frame is more stable, and overall strength and stability of the supporting frame is effectively improved.

Owner:CHANGSHU GAOJIA ENERGY TECH

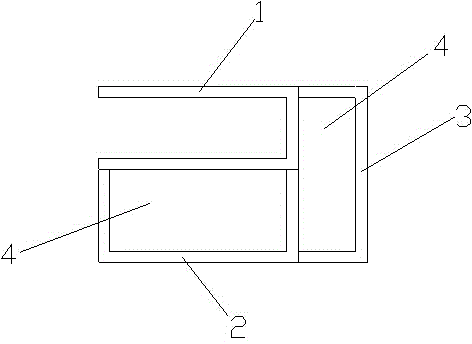

Solar module frame

InactiveCN104935244AEasy to useExtended service lifePhotovoltaicsPhotovoltaic energy generationMultiple frameEngineering

The invention discloses a solar module frame which is composed of multiple frame rods connected end to end. Each frame rod includes a clamp slot body and support bodies; the support bodies include a lower support body and a right support body; the clamp slot body is fixedly connected with the lower support body and the right support body through a welding process; and the lower support body and the clamp slot body form an independent hollow abdominal cavity structure, and the right support body and the clamp slot body form an independent hollow abdominal cavity structure. The invention provides a solar module frame which is unique in design and moderate in preparation cost. The support body structures are additionally arranged in the right and lower parts of the clamp slot body of each frame rod body, which greatly improves the stability of connection between the frame rods, enables the frame to have outstanding strength performance, and makes the solar module frame have better using performance and longer service life.

Owner:CHANGSHU DONGNENG PHOTOVOLTAIC TECH

Drill tool

ActiveUS9221108B2Raise the ratioOutstanding durabilityTransportation and packagingCutting insertsEngineeringDrill

A drill tool including a drill body having an inner insert and an outer insert at an end portion of the drill body. The distance from a central axis of the drill body to the outer insert is greater than the distance from the central axis to the inner insert. The cutting edges of the inner and outer inserts can be chamfered with the inner insert chambered at a radially inward portion and the outer insert chamfered at a radially outward portion. The inner insert and the outer insert can be mirror symmetric to one another. The inner insert and the outer insert are mounted to the drill body such that an effective cutting length of the inner insert equals an effective cutting length of the outer insert, the effective cutting lengths being measured in a direction perpendicular to the central axis.

Owner:TAEGUTEC

Addition reaction-curable organopolysilmethylenesiloxane copolymer composition

Owner:SHIN ETSU CHEM IND CO LTD

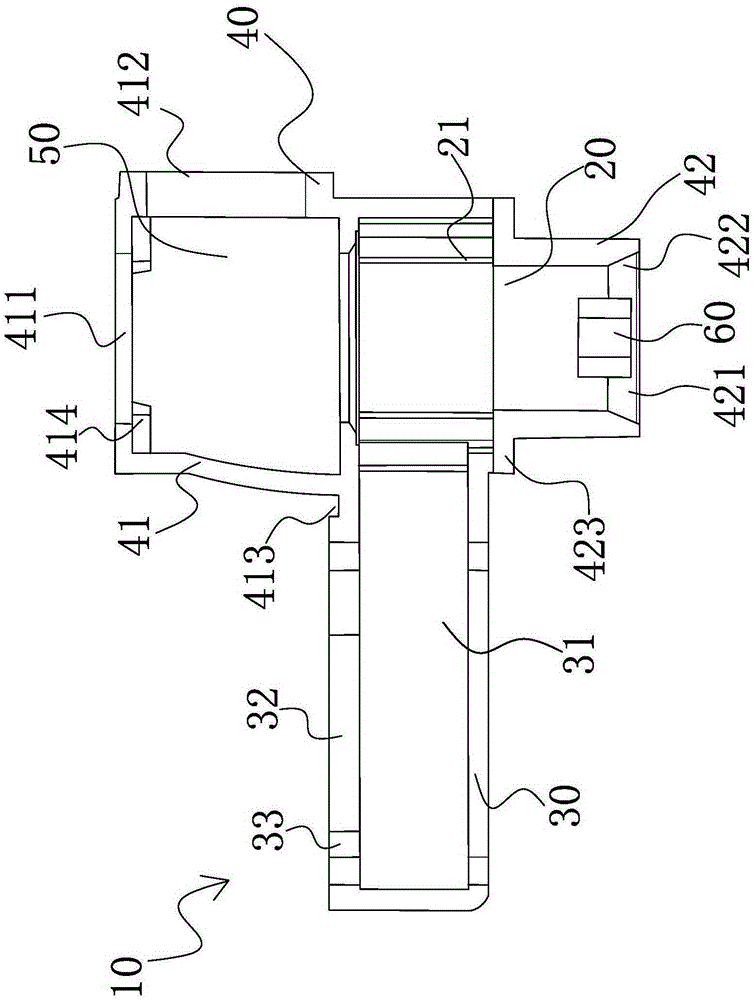

Electromagnetic valve suitable for air blower

InactiveCN105351566ASimple structureGood effectOperating means/releasing devices for valvesMultiple way valvesEngineeringAir blower

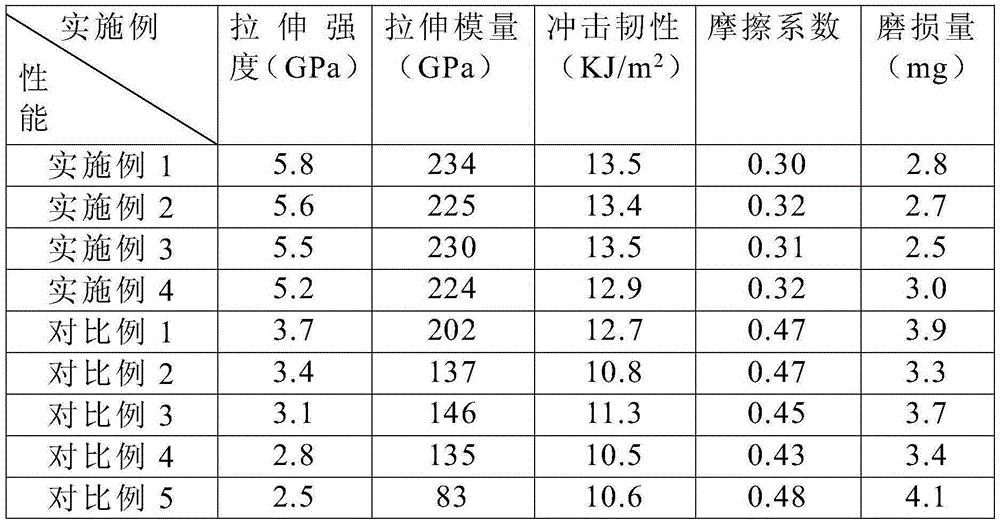

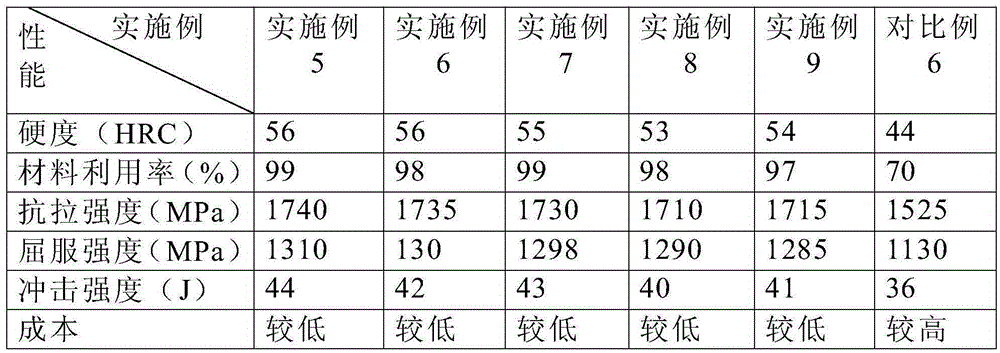

The invention relates to an electromagnetic valve suitable for an air blower. The electromagnetic valve suitable for the air blower comprises an electromagnetic valve body and a piston, wherein the cross section of the electromagnetic valve body is in a T shape, and the piston is inserted in the electromagnetic valve body. The electromagnetic valve body comprises an air inlet base and an air outlet base. An air inlet cavity and an air inlet are dug in the air inlet base. The air outlet base comprises a first air outlet piece and a second air outlet piece. Air outlet cavities are dug in the middle of the first air outlet piece and the middle of the second air outlet piece. An installation opening is formed in the upper end face of the first air outlet piece. A first air outlet is formed in the side face of the first air outlet piece. The lower end face of the first air outlet piece is fixedly connected with the upper end face of the second air outlet piece. A second air outlet is formed in the lower end face of the first air outlet piece. Electromagnets are inserted in the installation opening and the second air outlet respectively. The piston is installed in the air outlet cavities and can move in the air outlet cavities. The piston is made of composite materials. The electromagnetic valve suitable for the air blower is simple in structure and is integrally arranged; the piston, an air inlet base body and an air outlet base body are made of specific materials, the comprehensive performance of the electromagnetic valve is improved, and the service life of the electromagnetic valve is prolonged.

Owner:NINGBO SHENGHONG MACHINERY EQUIP

Hard capsule prepared through electrostatic spinning and preparation method of hard capsule

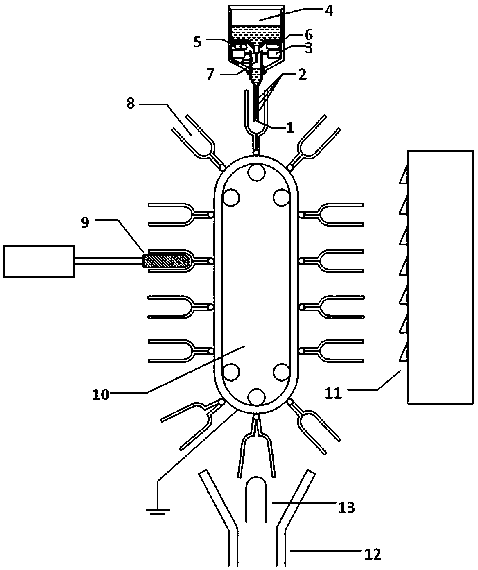

InactiveCN108210474AEasy to adjustEasy to controlFilament/thread formingCapsule deliveryFiberHard Capsule

The invention relates to a hard capsule prepared through electrostatic spinning and a preparation method of the hard capsule. The capsule is woven from nanoscale collagen fibers in an electrostatic spinning manner and has higher intensity and tenacity than the common wrapping and dipping capsule under the same thickness; in addition, the specific surface area of a material is greatly increased; the capsule has higher guest molecule inclusion capacity and faster digestion property; moreover, due to the specificity of a preparation technology, the multilayer and multistage capsule made from a composite can be prepared very conveniently; the wall thickness of the capsule is simple and easy to control; defective products hardly appear in a preparation process; the product quality is stabler and more controllable; the capsule is prepared by using a specific electrostatic spinning capsule blank-making machine and the matched preparation technology; a production process is fully automatic, safe and efficient; modules of equipment can be replaced according to different production requirements.

Owner:HUNAN ER KANG PHARMA

Zirconia molded body and pre-sintered body capable of being sintered in short time

PendingUS20220135486A1Outstanding strengthEasy to makeArtificial teethDentistry preparationsPolymer scienceFluorescence

A zirconia sintered body may excel in translucency, strength, in linear light transmittance, and can be produced by short-time sintering without an HIP device, and be used in zirconia molded bodies and pre-sintered bodies from which such a zirconia sintered body can be obtained. A zirconia molded body with zirconia particles and 2.0 to 9.0 mol % yttria, having an average primary particle diameter less than 60 nm, and a monoclinic crystal system in a fraction of ≥55%. The zirconia molded body may have ≥1% undissolved yttria. A zirconia pre-sintered body may have such zirconia particles, wherein the zirconia pre-sintered body has ΔL*(W−B) of ≥5 through a thickness of 1.5 mm. A zirconia sintered body may have a fluorescent agent and 2.0 to 9.0 mol % yttria, and a crystal grain size of ≤180 nm.

Owner:KURARAY NORITAKE DENTAL

Process for producing a fibrous bundle via a spinning nozzle

ActiveUS9834864B2Little adhesionImprove efficiencySpinnerette packsArtificial filament washing/dryingNanofiberSingle fiber

A spinning nozzle which has a perforated part in which ejection holes have been arranged in a density as high as 600-1,200 holes / mm2. This process for producing a fibrous bundle comprises ejecting a spinning dope having a viscosity as measured at 50° C. of 30-200 P from the ejection holes of the spinning nozzle to produce a fibrous bundle. This fibrous bundle has a single-fiber fineness of 0.005-0.01 dtex. By the wet-process direct spinning, a mass of nanofibers which are stably uniform and continuous can be produced at a high efficiency.

Owner:MITSUBISHI CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com