Heat-conductive silicone rubber composite sheet

A heat-conducting silicone rubber and composite sheet technology, which is applied in the direction of rubber layered products, semiconductor devices, coatings, etc., can solve the problems of reducing the thermal conductivity of composite sheets, and achieve excellent durability, excellent electrical insulation and mechanical strength levels , the effect of excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] [Preparation of thermally conductive composite sheet]

[0068]

[0069] First, using a mixing device such as a kneader, a Banbury mixer, a planetary mixer, or a Shinagawa mixer, if necessary, with heating to a temperature of about 100° C. or higher, the component (a) The organopolysiloxane and the thermally conductive filler of component (c) are kneaded together. In this kneading step, if desired, reinforcing silica such as fumed silica or precipitated silica, silicone oil or silicone wetting agent, or a flame retardant such as platinum, titanium oxide or benzo The triazole is added and mixed, provided that such addition does not affect the thermal conductivity of the outer layer.

[0070] The homogeneous mixture obtained by the kneading step is cooled to room temperature, and then filtered through a filter or the like. Subsequently, predetermined amounts of the adhesion promoter of component (d) and the curing agent of component (b) are added to the mixture, and se...

Embodiment 1

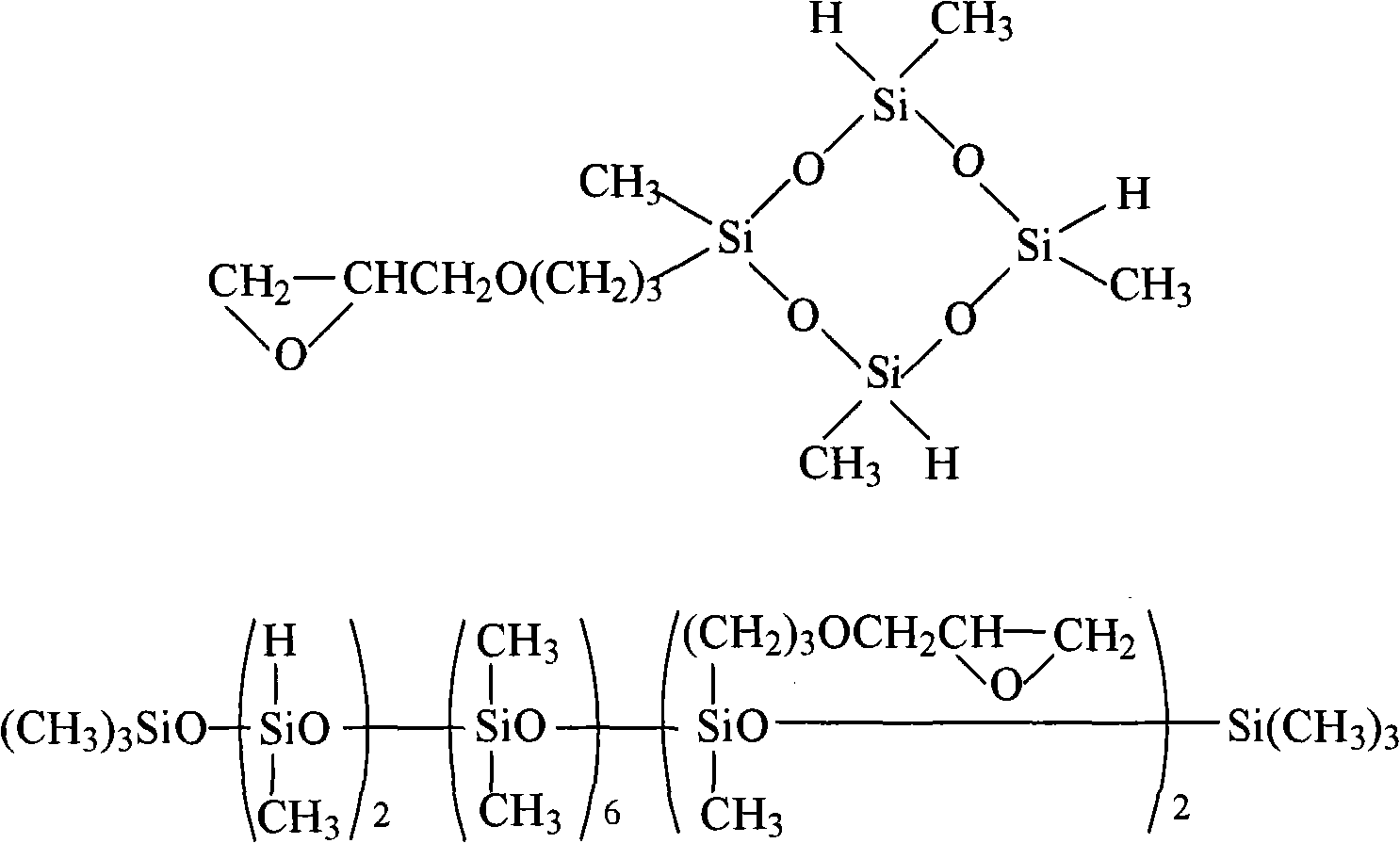

[0078] (a) 100 parts by mass of polydimethylsiloxane with an average degree of polymerization of 8000 whose both ends are capped with dimethylvinylsiloxy groups and (c) 750 parts by mass of polydimethylsiloxane with an average particle size of 4 μm The thermally conductive filler consisting of alumina powder was kneaded for 40 min at room temperature in a Banbury mixer. After filtering through a 100-mesh filter, 100 parts by mass of the mixture of (a)+(c) and (d) 1.0 parts by mass of an adhesion promoter composed of a silicon compound represented by the structural formula shown below:

[0079]

[0080] (b) 1.9 parts by mass of bis(2-methylbenzoyl) peroxide as an organic peroxide, and 0.4 parts by mass of colorant KE-color-R20 (product name, Shin-Etsu Chemical Co., Ltd.) were mixed, and then the resulting mixture was further kneaded using a two-roll mill to obtain a mixture.

[0081] Subsequently, 100 parts by mass of the mixture thus obtained was dissolved in 47 parts by m...

Embodiment 2

[0083] A thermally conductive silicone rubber composite sheet was prepared in the same manner as in Example 1, except that the amount of the silicon compound in component (d) was changed from 1.0 parts by mass to 0.5 parts by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com