Preparation method of high-compatibility magnesium-based biocomposite material

A composite material and compatibility technology, applied in the field of magnesium alloy materials, can solve the problems that the compatibility of magnesium alloy materials cannot effectively meet the performance of implant materials, so as to enhance free energy and hydrophilicity, and reduce tensile stress , Improve the effect of compatibility performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

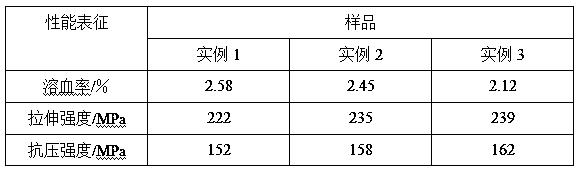

Examples

Embodiment Construction

[0022] In terms of parts by weight, weigh 10-15 parts of polytrimethylene fumarate, 10-15 parts of 200-mesh hydroxyapatite, 6-8 parts of N-methylpyrrolidone, and 1-2 parts of benzoyl peroxide , 3 to 5 parts of sodium chloride and 45 to 50 parts of 1,4-dioxane were placed in a three-necked flask, stirred and mixed and ultrasonically dispersed at 200 to 300W for 10 to 15 minutes, and then exchanged at 75 to 80°C After 3-5 hours of reaction, the cross-linking solution is obtained and the volume ratio is 1:1. The cross-linking solution and deionized water are stirred and mixed to obtain a mixed solution, and the mixed solution is placed at 55-60°C and rotated to evaporate to the volume of the mixed solution. 1 / 5 of 2-methacryloyloxyethylphosphorylcholine, 3-5 parts of methyl Add n-butyl acrylate, 1 to 2 parts of azobisisobutyronitrile and 45 to 50 parts of methanol, stir and mix and place in a water bath at 55 to 65°C for 15 to 20 hours to obtain a reaction solution with a volume ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com