Alkylation reaction product separation device and separation method

A technology of alkylation reaction and separation method, which is applied in the separation device and field of separation of alkylation reaction products, can solve the problems of obvious influence on selectivity, achieve obvious energy saving effect, reduce total energy consumption, and simple equipment and process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The alkylation reaction product comes from the isobutane and butene alkylation reaction unit of the solid acid alkylation technology. The solid acid alkylation catalyst used is a solid acid catalyst containing Y-type molecular sieve, produced by Catalyst Changling Branch of China Petroleum & Chemical Corporation, and the catalyst brand is AIB-2. The C4 fraction of the raw material for the alkylation reaction was obtained from Beijing Yanshan Branch of China Petrochemical Corporation, and its composition is shown in Table 1; the external alkene ratio is 25:1.

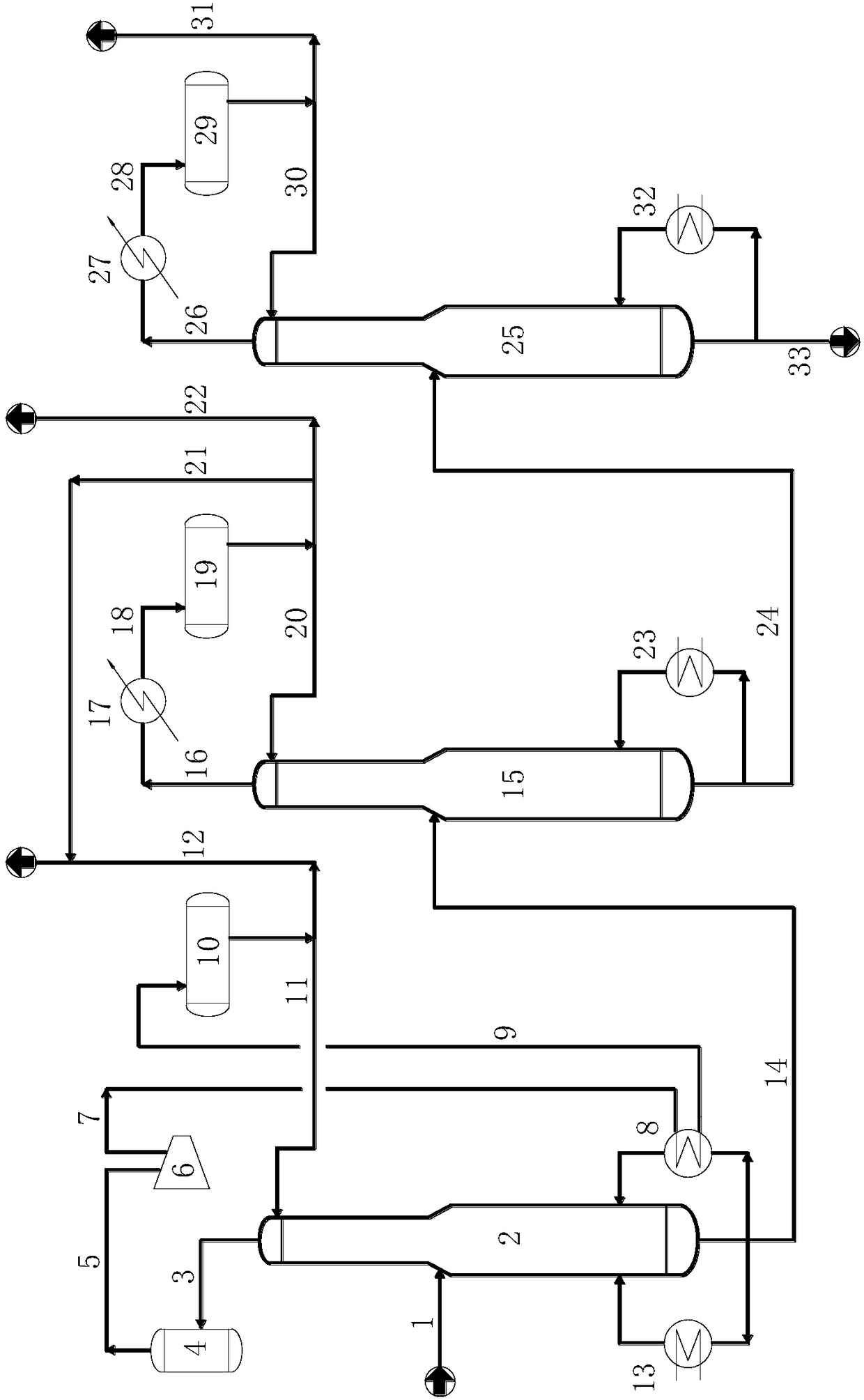

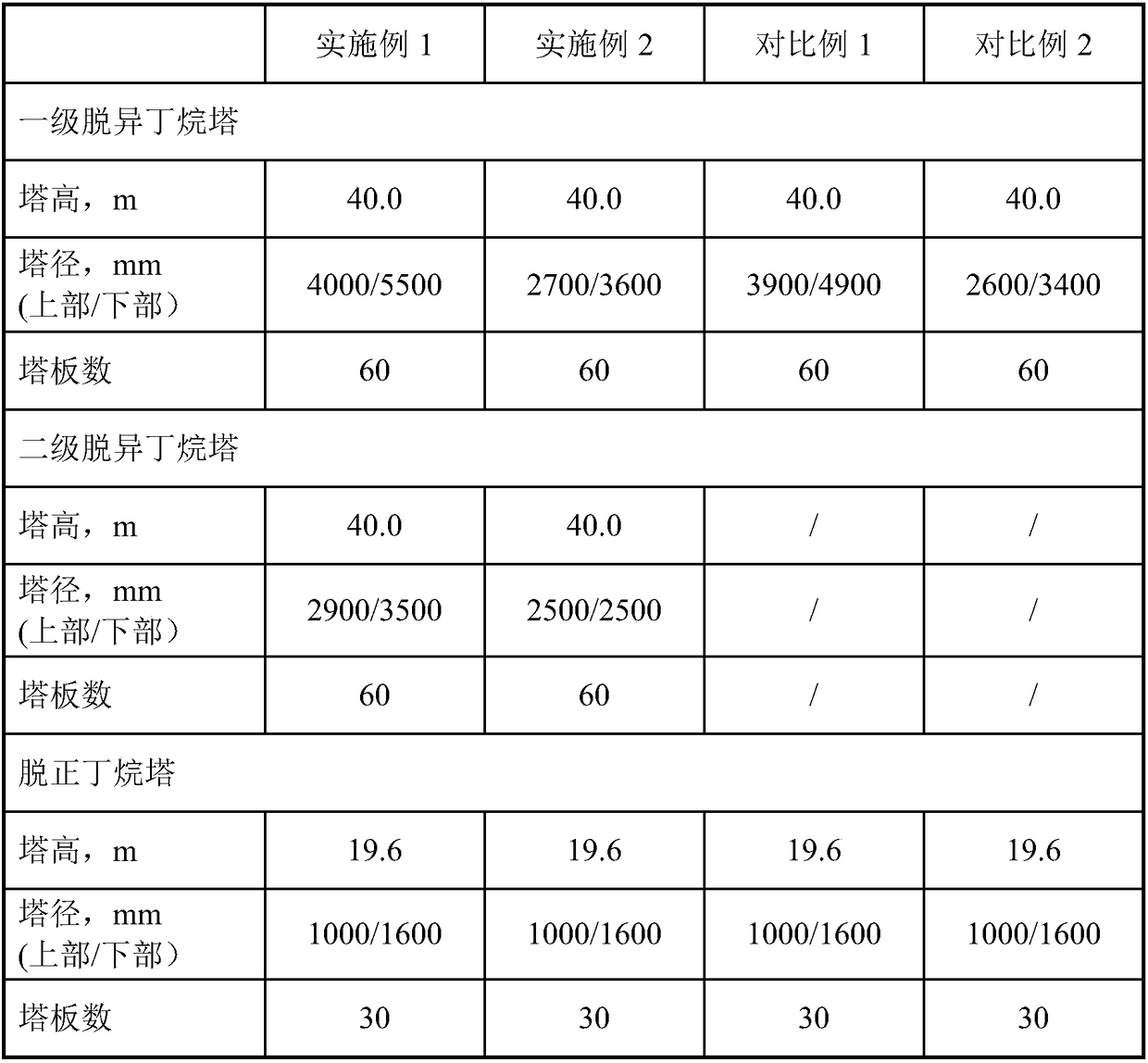

[0063] Alkylation reaction products were separated using an attached figure 1 In the alkylation reaction product separation device shown, the first fractionation tower is a first-stage de-isobutanizer, the second fractionation tower is a second-stage de-isobutanizer, and the third fractionation tower is a de-n-butanizer. The main structural parameters of the alkylation reaction product separation device are shown...

Embodiment 2

[0065] The alkylation reaction product comes from the isobutane and butene alkylation reaction unit of sulfuric acid alkylation technology. The catalyst is commercially available concentrated sulfuric acid having a concentration of 99.2% by mass. The C4 fraction of the raw material for the alkylation reaction is the same as that in Example 1, and the ratio of the external alkanes used in the sulfuric acid alkylation technology is 11:1, wherein the external alkanes provided by the primary de-isobutanizer and the secondary de-isobutanizer The ene ratio is 8:1.

[0066] Alkylation reaction products were separated using an attached figure 1 In the alkylation reaction product separation device shown, the first fractionation tower is a first-stage de-isobutanizer, the second fractionation tower is a second-stage de-isobutanizer, and the third fractionation tower is a de-n-butanizer. The main structural parameters of the alkylation reaction product separation device are shown in Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com