Urea-solution pyrolysis system for flue-gas denitrification

A technology of solution heat and urea, which is applied in the field of energy saving and emission reduction, can solve the problems of pipeline equipment blockage, short urea pyrolysis time, and blocked pipelines, so as to reduce the blockage and damage of pipeline equipment, increase the unit reaction area, avoid blockage and damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

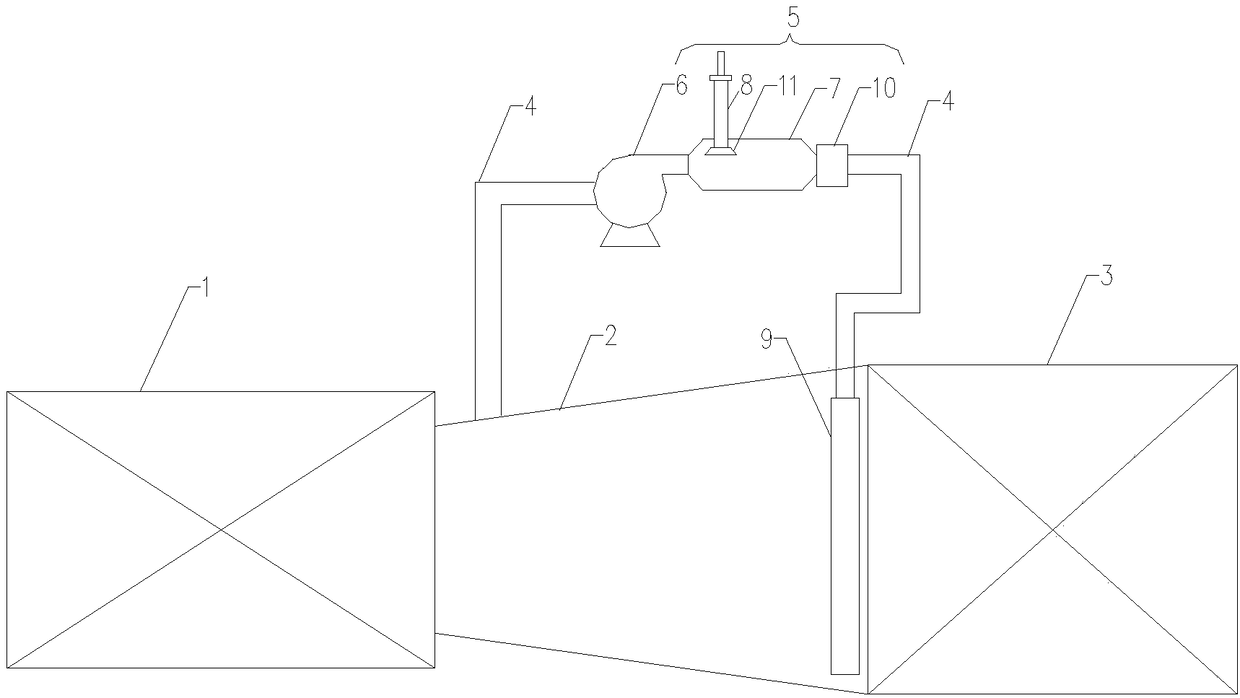

[0021] Embodiment 1 of the present invention: a kind of flue gas denitrification urea solution pyrolysis system, such as figure 1 As shown, it includes a gas turbine 1, a connecting flue 2, a waste heat boiler 3, an outlet flue 4 and a urea pyrolysis device 5, the gas turbine 1 and the waste heat boiler 3 are connected through a connecting flue 2, and the connecting flue 2 Both ends are externally connected with a lead-out flue 4, and the said lead-out flue 4 is provided with a urea pyrolysis device 5, wherein the urea pyrolysis device 5 includes a high-temperature blower fan 6, a diameter-expanding flue 7 and a urea spray gun 8, and the high-temperature The blower fan 6 is connected with the diameter-expanding flue 7, and the high-temperature fan 6 and the diameter-expanding flue 7 are arranged on the outlet flue 4, and the expanding-diameter flue 7 is also provided with a urea spray gun 8, in order to make the urea spray gun 8 The urea solution sprayed in can be more fully p...

Embodiment 2

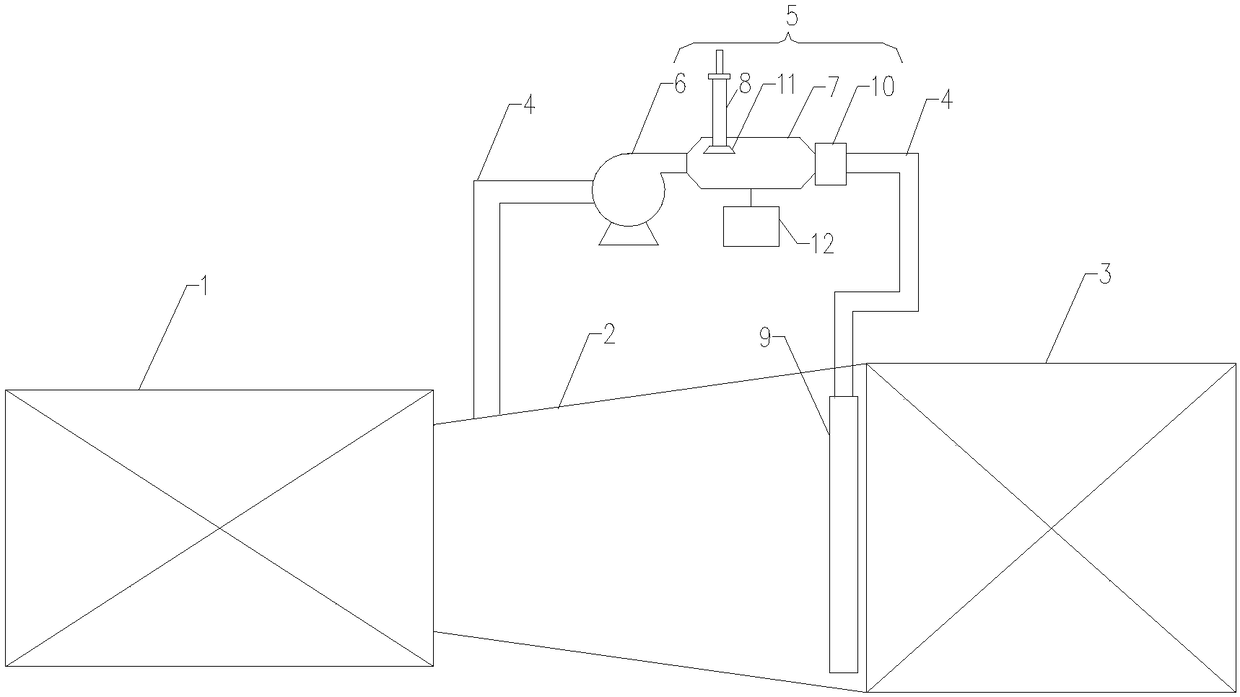

[0022] Embodiment 2: A kind of flue gas denitrification urea solution pyrolysis system, such as figure 2 As shown, it includes a gas turbine 1, a connecting flue 2, a waste heat boiler 3, an outlet flue 4 and a urea pyrolysis device 5, the gas turbine 1 and the waste heat boiler 3 are connected through a connecting flue 2, and the connecting flue 2 Both ends are externally connected with a lead-out flue 4, and the said lead-out flue 4 is provided with a urea pyrolysis device 5, wherein the urea pyrolysis device 5 includes a high-temperature blower fan 6, a diameter-expanding flue 7 and a urea spray gun 8, and the high-temperature The blower fan 6 is connected with the diameter-expanding flue 7, and the high-temperature fan 6 and the diameter-expanding flue 7 are arranged on the outlet flue 4, and the expanding-diameter flue 7 is also provided with a urea spray gun 8, in order to make the urea spray gun 8 The urea solution sprayed in can be more fully pyrolyzed to obtain ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com