Preparation method and application of composite modified straw active granule carbon adsorption material

A technology of composite modification and active particles, which is applied in the field of agricultural and forestry waste recycling and water treatment, can solve the problems of poor adsorption effect, easy slag drop, and difficult wave of modified straw biochar, so as to reduce eutrophication Phenomenon, the effect of improving the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

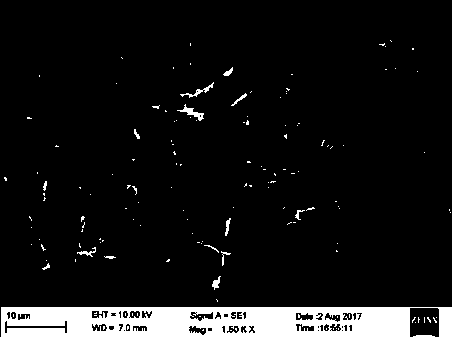

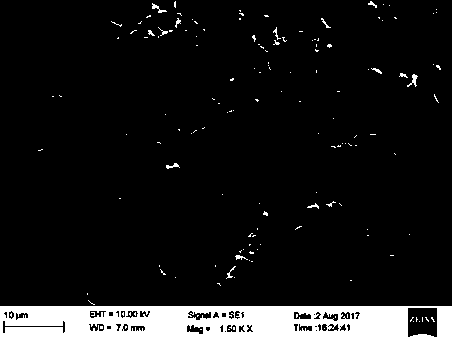

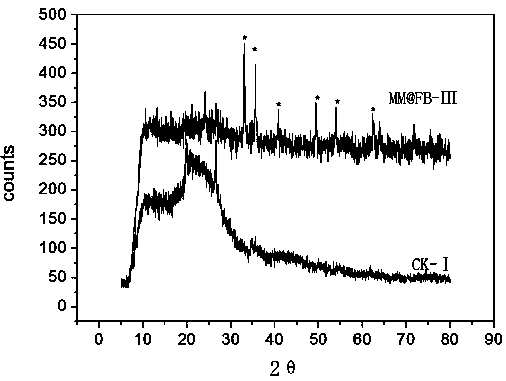

Image

Examples

Embodiment 1

[0036] Example 1 Preparation of composite modified straw activated granular carbon adsorption material

[0037] A) Preparation of straw granular carbon

[0038] 1) Straw composite particles: Premix 1000g rice straw powder with a particle size of 40~60 mesh, 1500g distilled water, 100g methylcellulose, 125g nano-montmorillonite and 125g negative ion powder in a high-speed mixer for 30 minutes, and then transfer the materials To the turntable granulator, the inclination angle of the turntable is set to 30°, and the rotation speed is 20rpm for granulation to obtain straw composite granules with a particle size range of 0.5-6mm.

[0039] 2) Preparation of straw granular carbon: put the straw granular carbon in a tube furnace for pyrolysis at a heating rate of 5°C / min, and pyrolyze at 350°C for 6h;

[0040] B) Preparation of composite modified straw activated granular carbon

[0041] 1) Put 200mL magnesium chloride solution with a molar concentration of 0.85mol / L and 100mL ferric...

Embodiment 2

[0046] A) Preparation of straw granular carbon

[0047] 1) Straw composite granules: Premix 1000g coconut shell powder, 500g distilled water, 800g methyl cellulose and 200g methyl hydroxyethyl cellulose with a particle size of 40~60 mesh in a high-speed mixer for 5 minutes, and then transfer the materials to Turntable granulator, the inclination angle of the turntable is set to 60°, and the rotating speed is 60rpm for granulation to obtain straw composite granules with a particle size range of 0.5-6mm.

[0048] 2) Preparation of straw granular carbon: put the straw granular carbon in a tube furnace for pyrolysis at a heating rate of 10°C / min, and pyrolyze at 750°C for 1 hour;

[0049] B) Preparation of composite modified straw activated granular carbon

[0050] 1) Put 200mL magnesium chloride solution with a molar concentration of 0.55mol / L, 50mL ferric chloride solution with a molar concentration of 0.45mol / L, and 50mL aluminum chloride solution with a molar concentration of...

Embodiment 3

[0053] A) Preparation of straw granular carbon

[0054] 1) Straw composite particles: 1000g wheat straw powder with a particle size of 40~60 mesh, 800g distilled water, 400g methyl cellulose and 600g methyl hydroxyethyl cellulose, 150g nano-montmorillonite and 100g negative ion powder in a high-speed mixer The mixture was premixed for 15 minutes, and then the material was transferred to a turntable granulator. The inclination angle of the turntable was set at 45°, and the rotation speed was 40rpm for granulation to obtain straw composite granules with a particle size range of 0.5-6mm.

[0055] 2) Preparation of straw granular carbon: put the straw granular carbon in a tube furnace for pyrolysis at a heating rate of 8°C / min, and pyrolyze at 450°C for 4h;

[0056] B) Preparation of composite modified straw activated granular carbon

[0057] 1) Put 200mL magnesium chloride solution with a molar concentration of 0.55mol / L, 50mL ferric chloride solution with a molar concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com